An ultrasonic plastic welding machine for auto parts processing

An auto parts, ultrasonic technology, applied in cleaning methods and utensils, chemical instruments and methods, dust removal, etc., can solve problems such as difficult to discharge, easy to accumulate disease, affect the health of workers, etc., to reduce ionizing radiation and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

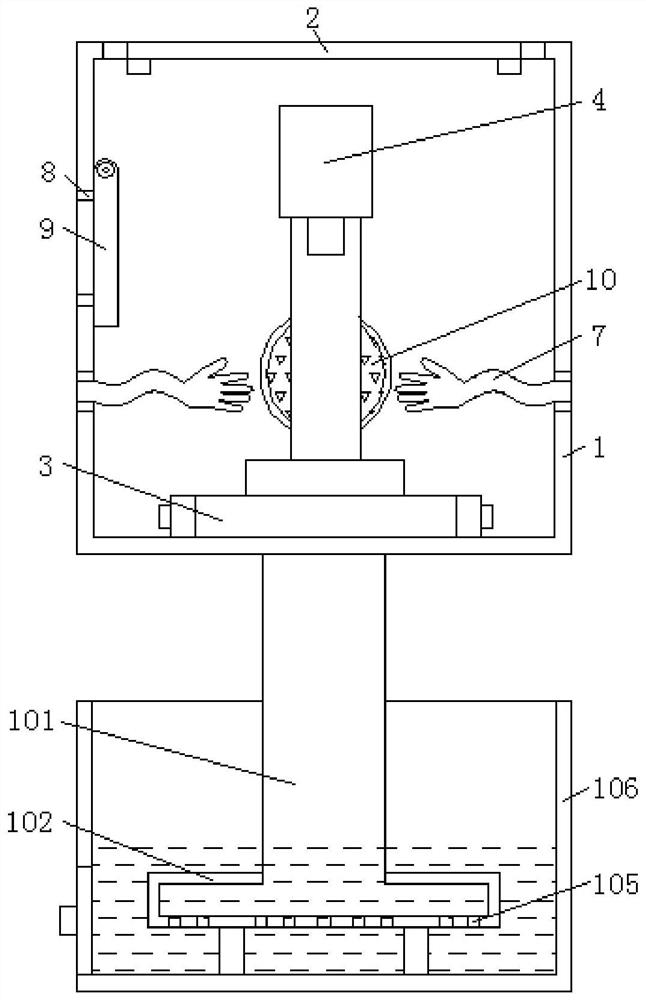

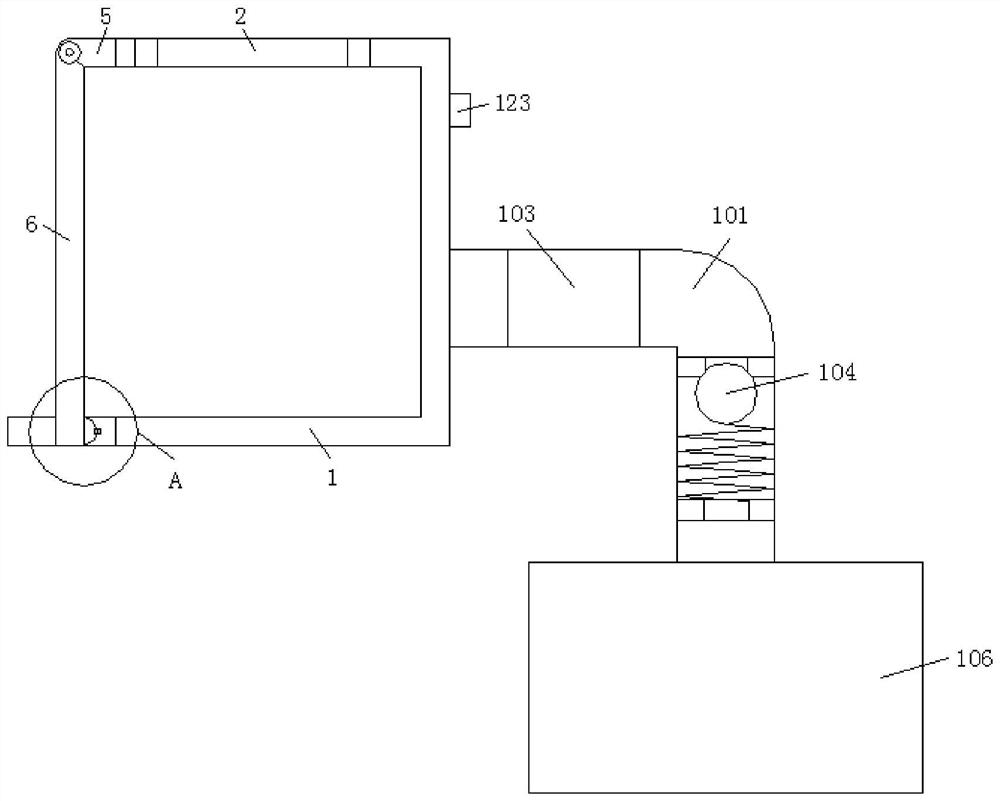

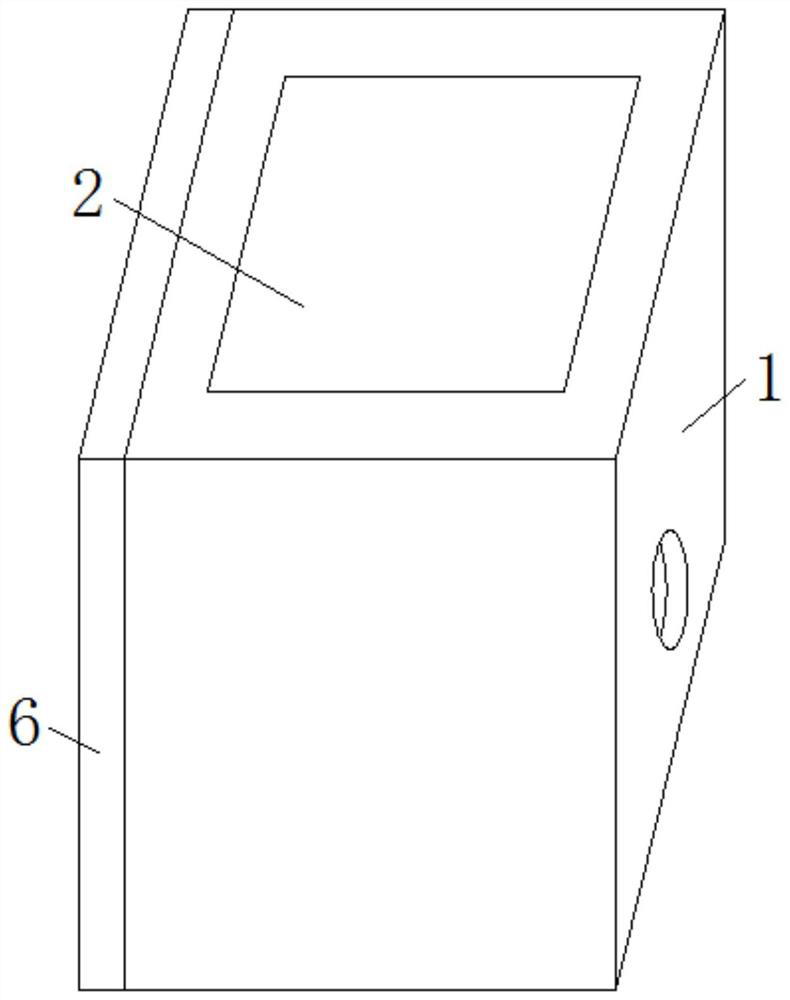

[0038] An ultrasonic plastic welding machine for auto parts processing, such as Figure 1-3 As shown, including the main body box 1, the inner top wall of the main body box 1 is provided with an observation port, and the inner wall of the observation port is fixedly connected with a first isolation ring, and the inner wall of the first isolation ring is connected with the inner top wall of the main body case 1 and the main body case 1 respectively. The upper surface is fixedly connected, the inner wall of the first isolation ring is fixedly connected with the observation board 2 , and the lower surface of the observation board 2 is fixedly connected with a supplementary light.

[0039] The inner bottom wall of the main body box 1 is fixedly connected with a fixed block, and the surfaces of a plurality of fixed blocks are fixedly connected with a base 3 by bolts. The surface of the column is fixedly connected with an ultrasonic generator 4, and the lower surface of the ultra-wi...

Embodiment 2

[0044] An ultrasonic plastic welding machine for auto parts processing, such as Figure 1-3 As shown, including the main body box 1, the inner top wall of the main body box 1 is provided with an observation port, and the inner wall of the observation port is fixedly connected with a first isolation ring, and the inner wall of the first isolation ring is connected with the inner top wall of the main body case 1 and the main body case 1 respectively. The upper surface is fixedly connected, the inner wall of the first isolation ring is fixedly connected with the observation board 2 , and the lower surface of the observation board 2 is fixedly connected with a supplementary light.

[0045] The inner bottom wall of the main body box 1 is fixedly connected with a fixed block, and the surfaces of a plurality of fixed blocks are fixedly connected with a base 3 by bolts. The surface of the column is fixedly connected with an ultrasonic generator 4, and the lower surface of the ultra-wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com