Bookbinding machine

A binding machine and fuselage technology, applied in binding and other directions, can solve problems such as improper operation, low efficiency, and limb injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

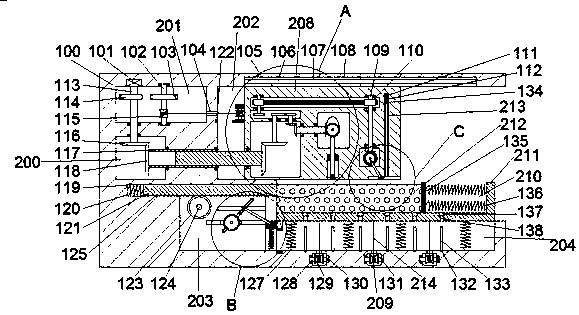

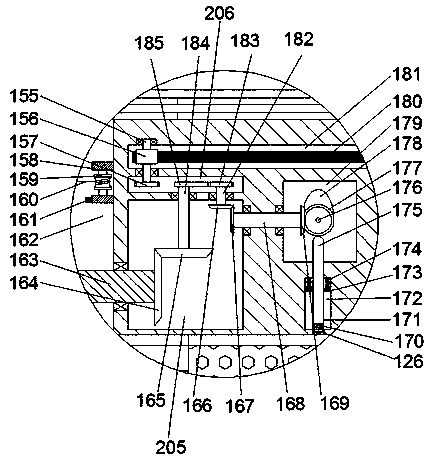

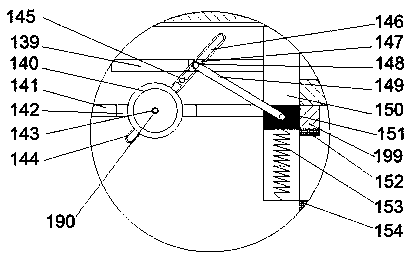

[0016] Such as Figure 1-Figure 4As shown, a binding machine of the present invention includes a body 100 and a first cavity 200 disposed in the left end wall of the body 100, and a second cavity 201 is disposed in the top wall of the first cavity 200 A first rotating shaft 113 is rotatably arranged between the second cavity 201 and the first cavity 200, and the top end of the first rotating shaft 113 in the second cavity 201 is fixedly arranged on the first rotating shaft 113. The first motor 101 in the top wall of the two cavities 201 is power-connected, the outer surface of the first rotating shaft 113 in the second cavity 201 is fixedly provided with a first sector gear 114, and the first sector gear 114 in the first cavity 200 is The end of the first rotating shaft 113 is fixedly provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com