Calcium sulfate opening master batch and preparation method thereof

A technology of opening masterbatch and calcium sulfate, which is applied in the field of agricultural film manufacturing, can solve the problems of easy expansion and broken strips, low production efficiency, low density of opening agent, etc.

Inactive Publication Date: 2019-01-18

NORTH HUAJIN CHEM IND CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Some anti-blocking agents have low density, easy to expand and break during production, and the production efficiency is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0015] Preparation of Calcium Sulfate Open Masterbatch:

[0016] Low-density polyethylene powder (LLDPE): 90kg

[0017] Commercially available calcium sulfate opening agent: 8kg

[0018] Compound antioxidant (B215): 0.1kg

[0019] Paraffin oil (150): 1.9kg

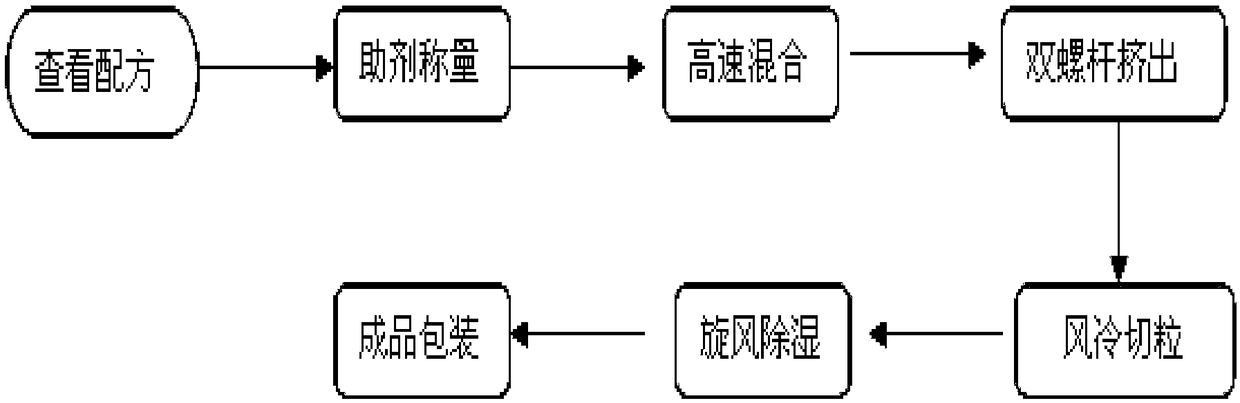

[0020] The above components are accurately weighed, put into a high-speed mixer for stirring, and granulated by a twin-screw extruder to produce a finished product.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of agricultural film manufacture and in particular relates to a calcium sulfate opening master batch and a preparation method thereof. The calcium sulfate opening master batch contains the following components in percentage by mass: 89-91% of linear low-density polyethylene powder (LLDPE), 7.9-8.1% of a commercially available calcium sulfate opening agent, 0.09-0.11% of a composite antioxidant and 1.9-2.1% of paroline. The preparation method comprises the following steps: accurately weighing various components by an electronic scale, adding the components into a high-speed mixing machine, closing the upper cover of a stock bin, and mixing at a high speed for 1-3 minutes; feeding into a twin-screw extruder after mixing completion, fully plastifying the materials by virtue of the pressure and shear force produced by screw rotation, uniformly mixing, performing mouth model molding, performing cutting molding by a dicing cutter, dehumidifying by a cycloneseparator, and thus producing the finished product. According to the product disclosed by the invention, the frictional resistance in the film production process can be effectively reduced, vesicle breath is reduced, the opening performance of the product is excellent, the design expectation is met, and the film production is met.

Description

technical field [0001] The invention belongs to the field of agricultural film manufacture, and in particular relates to a calcium sulfate open masterbatch and a preparation method thereof. Background technique [0002] In the production process of plastic film, in order to prevent the film products from sticking together and opening is difficult, it is necessary to add a certain amount of opening masterbatch. There are many types of opening masterbatches on the market, including the use of opening agents such as oils, minerals, talcum powder, and silicon dioxide. When using oils, minerals, talcum powder, silicon dioxide, etc. as the production of opening masterbatch, the micropowder with large mesh size is generally selected. The common problem is that the high amount of micropowder added has a certain impact on the transparency of the film. Some anti-blocking agents have low density, and are easy to expand and break during production, resulting in low production efficienc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/08C08L91/06C08K3/30C08J3/22C08J5/18

CPCC08J3/226C08J5/18C08J2423/08C08K2003/3045

Inventor 赵立功王伟范立成柳波胡云强王宇姜翠常晓颖

Owner NORTH HUAJIN CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com