Plant coke dry quenching furnace and coke dry quenching system

A CDQ technology for coke ovens and factories, applied in coke ovens, petroleum industry, coke cooling, etc., can solve the problems of waste of resources, air pollution, etc., and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be explained in detail in conjunction with the accompanying drawings and specific embodiments.

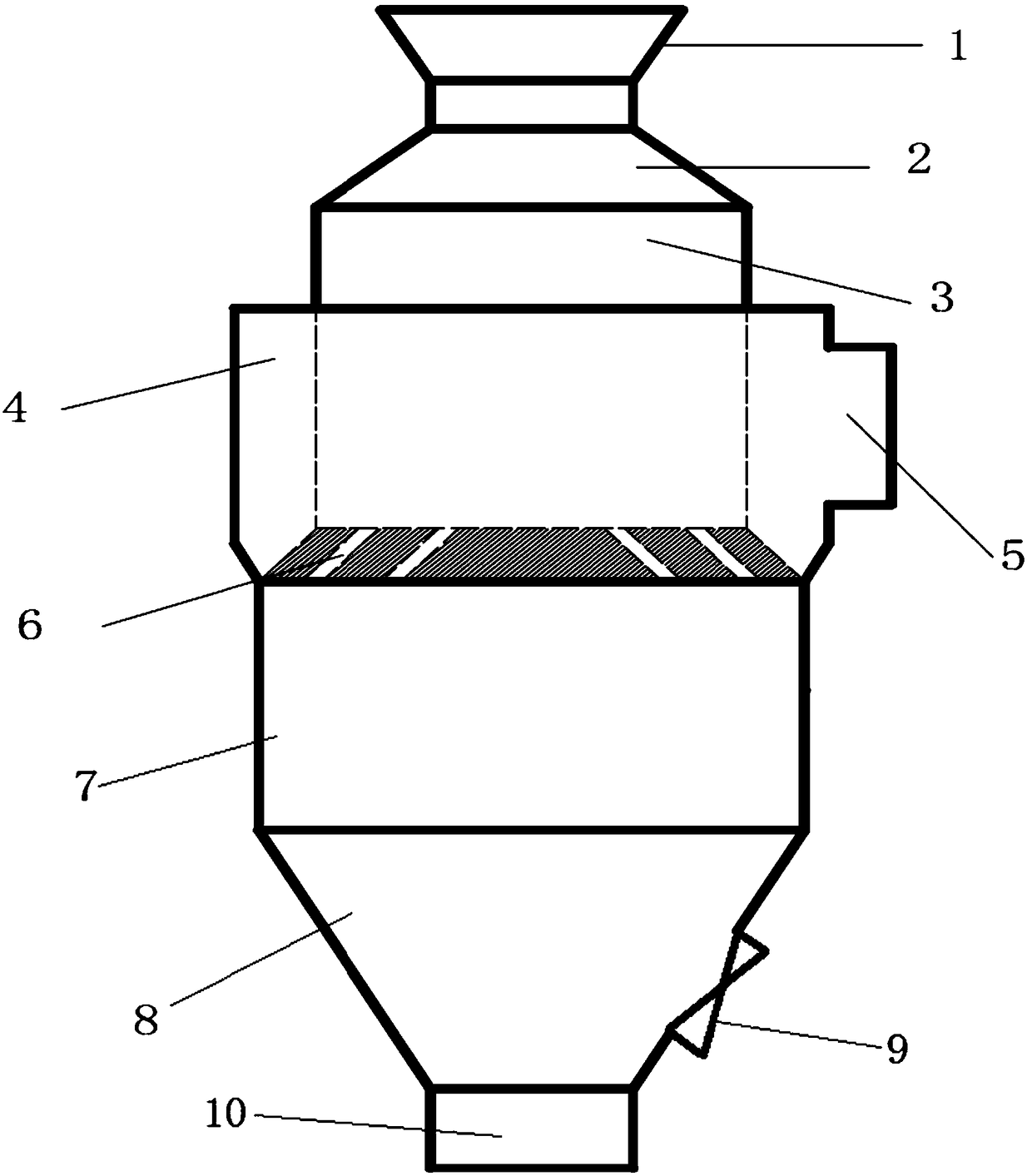

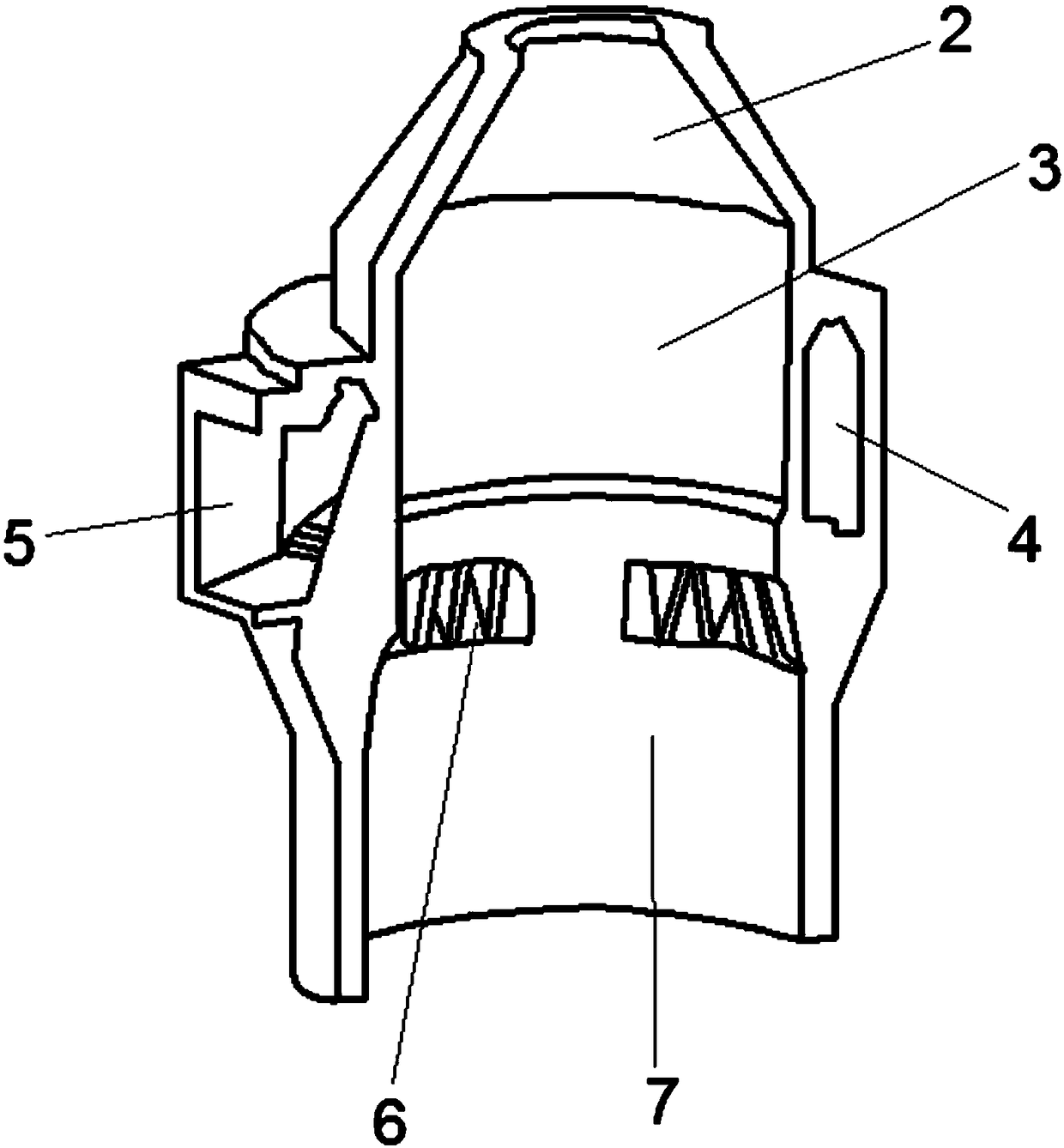

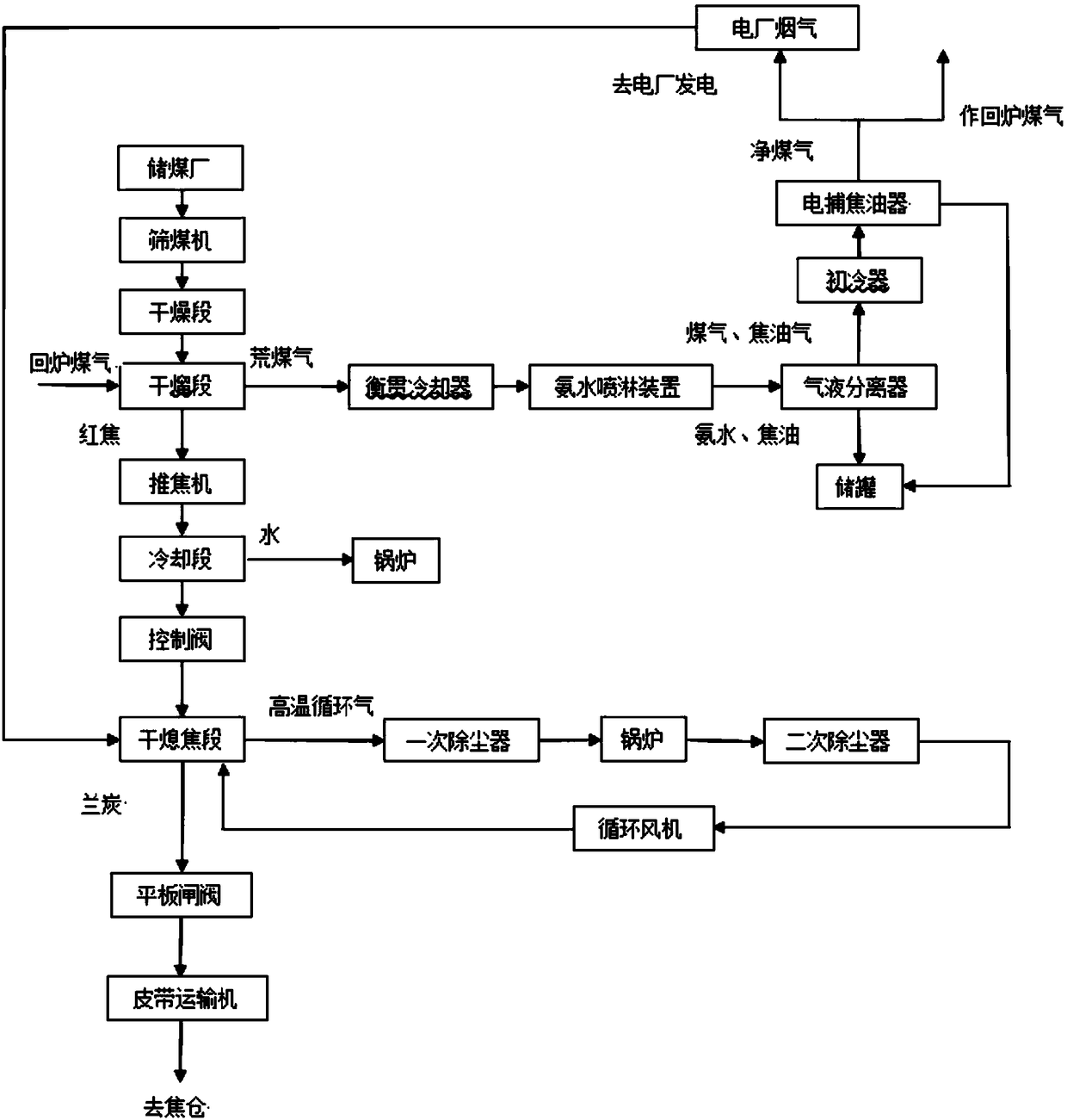

[0023] combine figure 1 and figure 2 As shown, it is the CDQ coke oven in the factory of the present invention, including furnace mouth 1, furnace roof 2, pre-storage chamber 3, annular gas channel 4, circulating gas cooling chamber 7, circulating gas distribution chamber 8 and coke discharge port 10, pre-storage chamber 3. Both the circulating gas cooling chamber 7 and the circulating gas distribution chamber 8 are cavity structures, and the pre-storage chamber 3 and the circulating gas cooling chamber 7 are cylindrical structures, and the circulating gas distribution chamber 8 is a conical structure. The upper end of the circulating gas cooling chamber 7 is fixedly connected to the lower end of the pre-storage chamber 3, and the lower end of the circulating gas cooling chamber 7 is fixedly connected to the upper end of the cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com