Water-saving washing tank for diesel engine exhaust gas

A technology for washing tanks and diesel engines, which is applied to exhaust devices, mechanical equipment, engine components, etc. It can solve the problems of high pressure of water-air mixture without sufficient separation, fast water consumption, and manual water replenishment, so as to avoid large-scale occupation and water consumption. Thorough separation and reduced mist generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

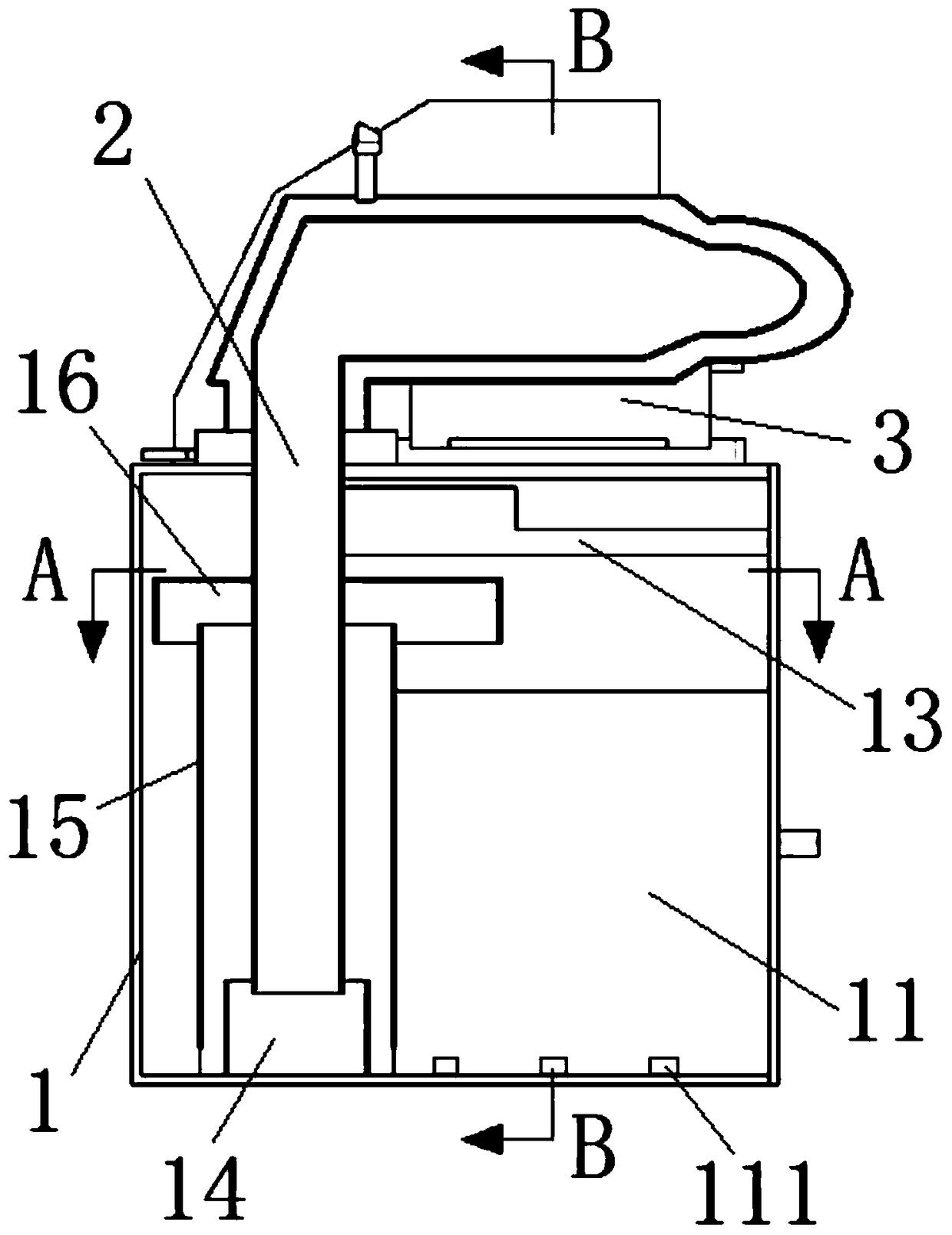

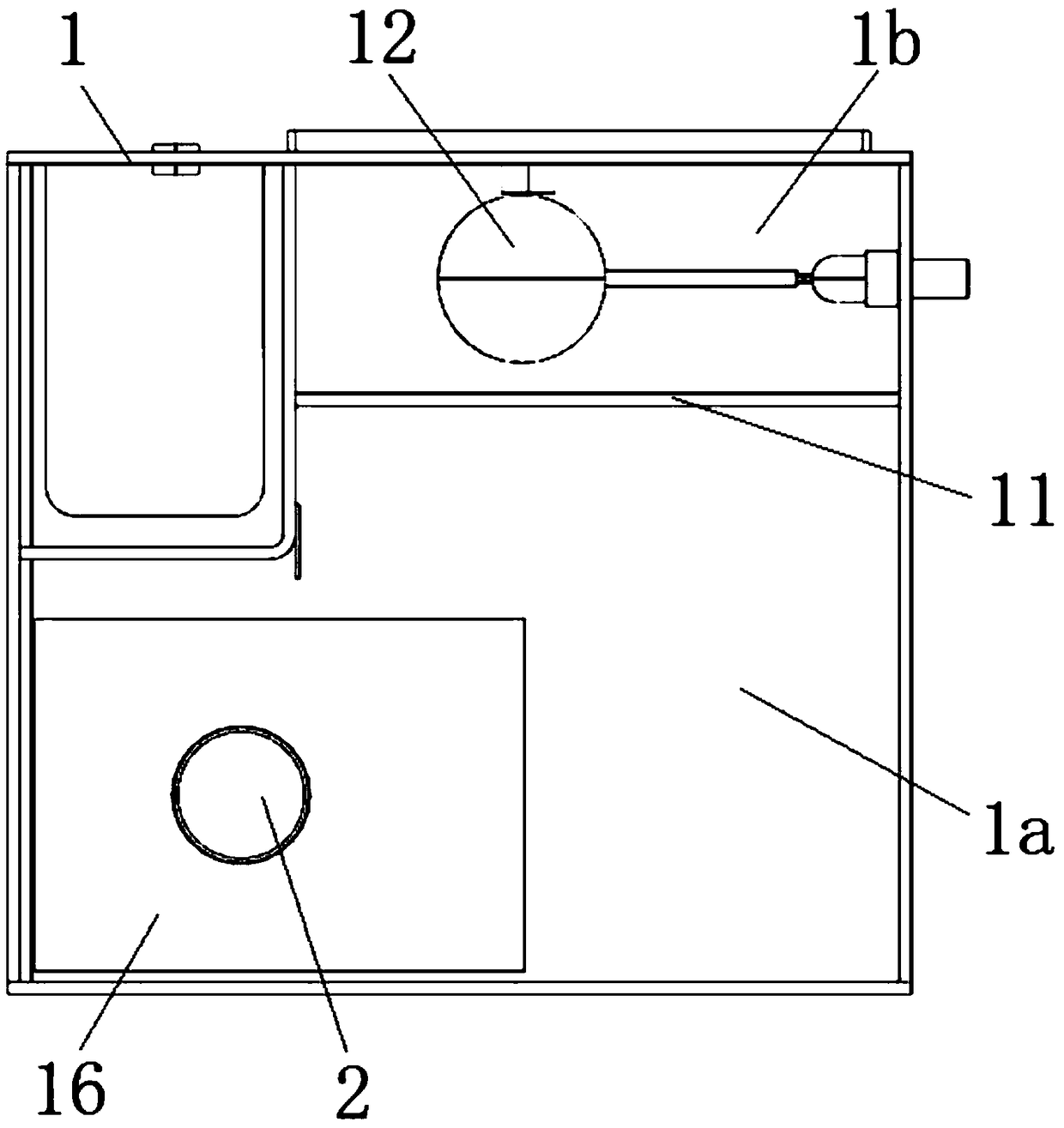

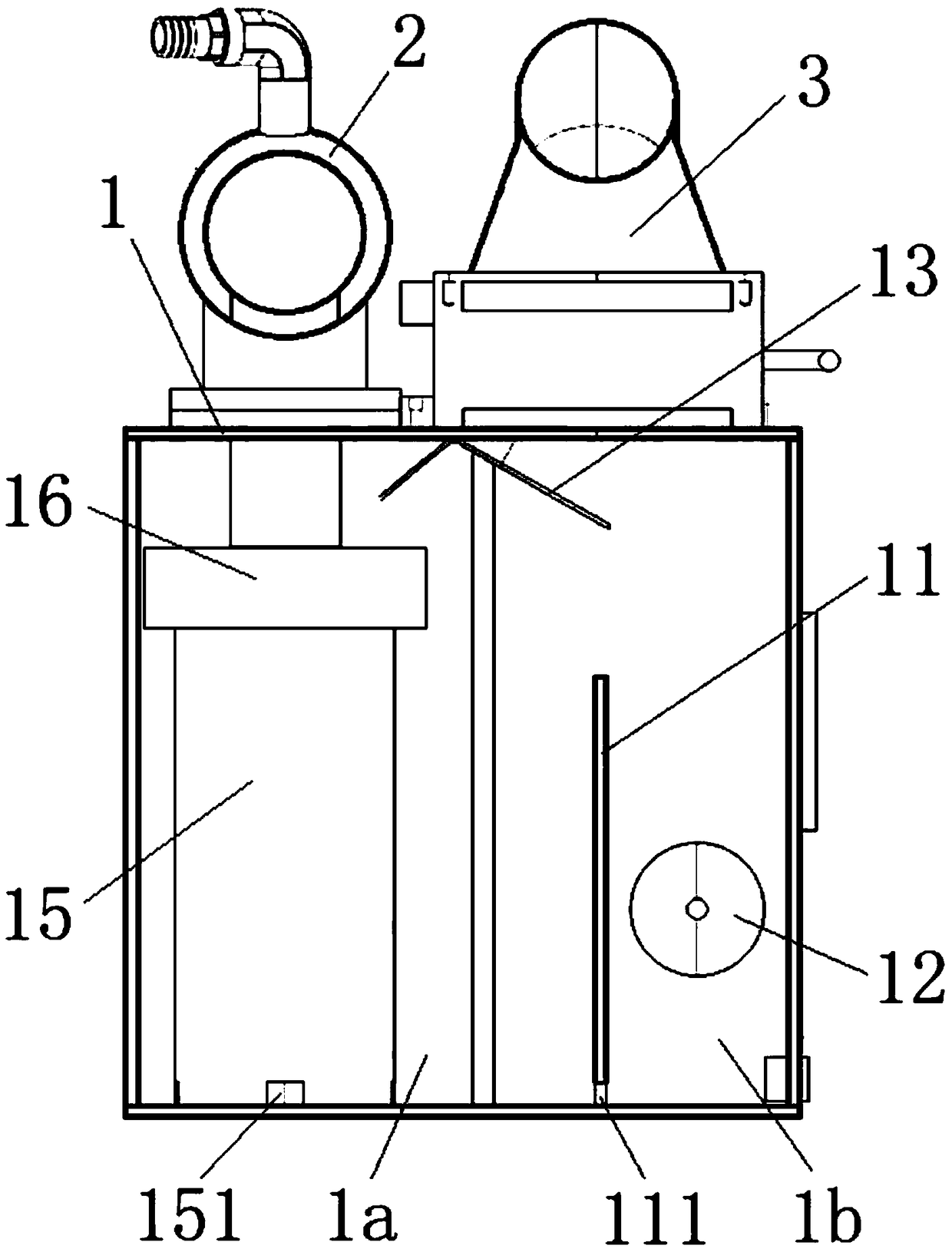

[0022] like Figure 1 to Figure 3 As shown, a diesel engine exhaust water washing box of the present invention includes a water washing box 1 divided into a water inlet chamber 1a and a replenishing water chamber 1b by a partition 11, an air intake pipe 2 inserted into the depth of the water inlet chamber 1a, and an access water washing box 1 The upper air outlet pipe 3 and the bottom of the partition 11 are provided with a water hole 111 for the water inlet chamber 1a and the water replenishment chamber 1b to pass through. The middle cylinder 14 and outer cylinder 15 at the bottom and the water shield 16 sleeved on the intake pipe 2, the diameter of the middle cylinder 14 is greater than the diameter of the intake pipe 2 and the highest position is higher than the lowest point of the intake pipe 2, the outer cylinder 15 Bottom is provided with drain hole 151, and the caliber of outer tube 15 is larger than the caliber of intermediate tube 14 and is higher than the upper edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com