Wood drying device

A wood drying and rotating shaft technology, which is applied in wood drying, dry solid materials, dry cargo handling, etc., can solve problems affecting processing efficiency and labor costs, improve automation and practicability, improve efficiency, and facilitate installation and maintenance The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] figure 1 It is an external schematic diagram of the overall structure of a wood drying device in the present invention;

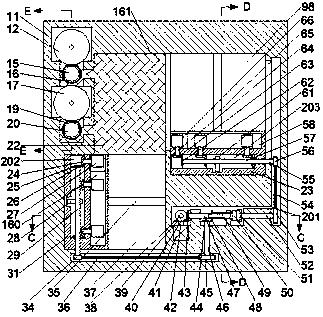

[0021] figure 2 Yes figure 1 Schematic diagram of the structure of A-A;

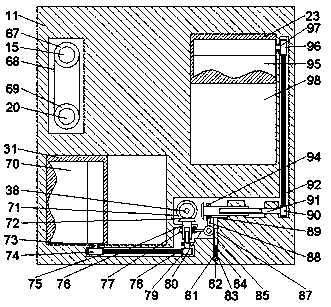

[0022] image 3 Yes figure 1 Schematic diagram of the structure of B-B;

[0023] Figure 4 Yes figure 2 Schematic diagram of the structure of C-C;

[0024] Figure 5 Yes figure 2 Schematic diagram of the structure of D-D;

[0025] Image 6 Yes figure 2 Schematic diagram of the structure of E-E;

[0026] Figure 7 Yes Image 6 Schematic diagrams of the structures of F–F.

[0027] like Figure 1-Figure 7As shown, a wood drying device of the present invention includes a fuselage 11 and a first cavity 201 is arranged in the fuselage 11, and a first rotating shaft 40 extending forward and backward is rotatably arranged in the first cavity 201. , the front end of the first rotating shaft 40 is power-connected with the motor 41 arranged in the front end wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com