A high-precision 3D printer

A 3D printer, high-precision technology, applied in the field of printers, can solve problems such as troublesome adjustment, unadjustable precision, and reduced printing accuracy of the printer, and achieve the effects of uniform and precise thickness, convenient height adjustment, and precise spacing control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

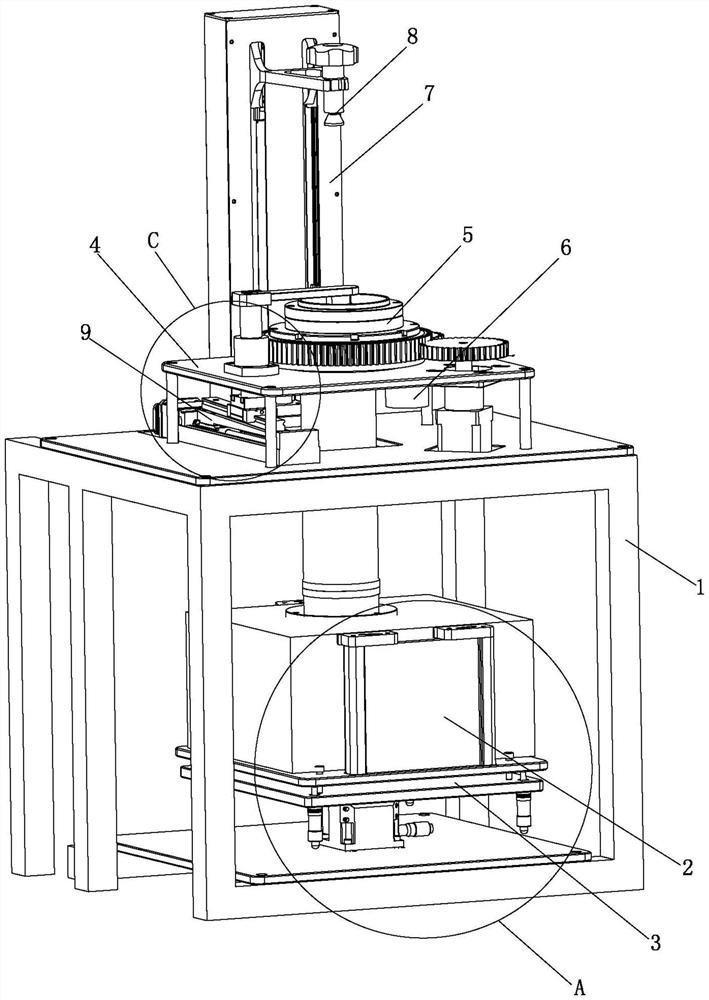

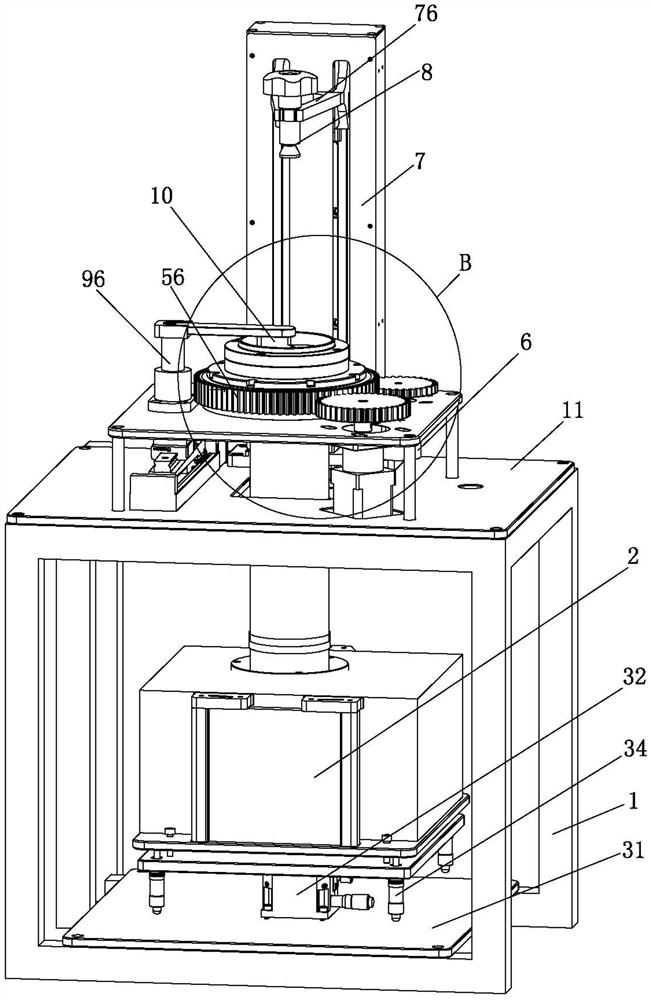

[0032] Please refer to the attached figure 1 To attach Figure 7 As shown, the present invention is a high-precision 3D printer, which consists of a frame 1, an optical machine 2, an optical-mechanical adjustment mechanism 3, a mounting plate 4, a material holding mechanism 5, an encoder 6, a Z-axis module 7, and a printing platform 8 and scraper height adjustment mechanism 9 and other parts.

[0033] Wherein, the optical machine 2 is installed on the frame 1 through the optical machine adjustment mechanism 3 , and the optical machine adjustment mechanism 3 can adjust the position of the optical machine 2 . The optical machine 2 is a commercially available high-precision optical machine, so details will not be repeated here.

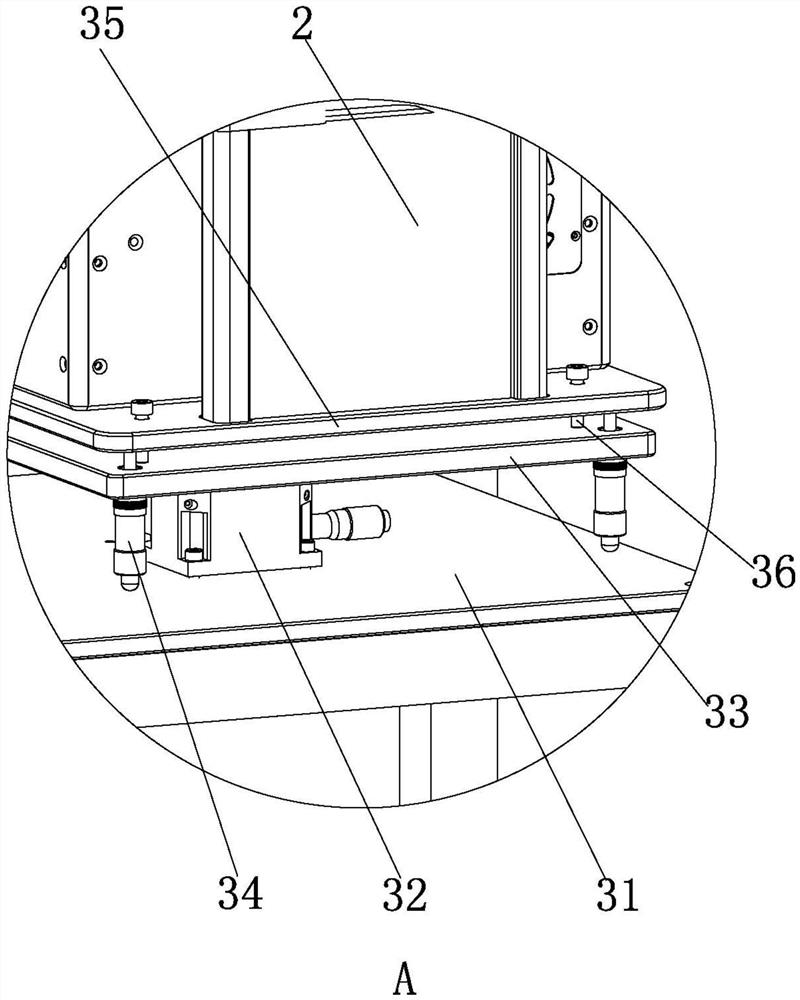

[0034] Specifically, the optical-mechanical adjustment mechanism 3 is composed of a bottom plate 31 , an optical-mechanical coarse adjustment seat 32 , a lower adjustment plate 33 , an optical-mechanical leveling differential nut 34 , and an upper adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com