Powder charging hole sealing method applied to top plate deep hole pre-splitting blasting

A technology for pre-split blasting and blasting holes, which is applied in the field of pre-split blasting and sealing of deep holes in the roof, can solve the problems of poor sealing effect, insufficient sealing resistance, low labor efficiency, etc. The effect of many times of use and improved economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

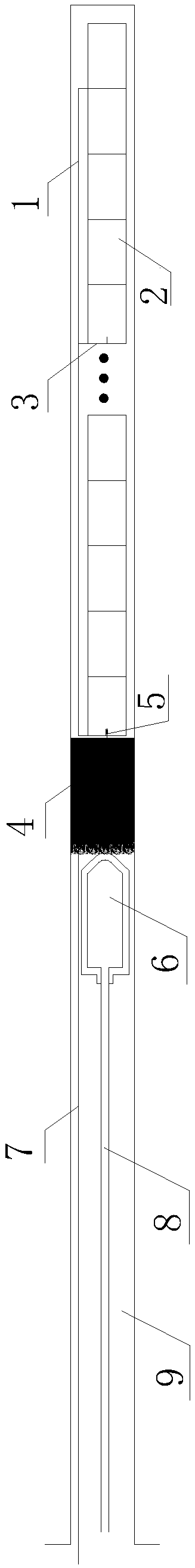

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] In this embodiment, the diameter of the pre-splitting blast hole 9 on the roof is 89 mm, and the hole depth is 35 m.

[0021] like figure 1 As shown, a charge sealing method for roof deep hole pre-splitting blasting includes a rubber sealer 6, a charge coil group, a charge coil 2, an anchoring agent 4 and a detonator, and each charge coil group consists of Composed of several drug rolls 2, the drug roll 2 is composed of a reel and explosives filled in the reel. One end of the reel is provided with a threaded inner hole, and the other end is provided with an external thread. The ends of several drug reels 2 are threaded. Holes and external threads are assembled and connected. Among them, the explosive is the second-grade coal mine-permitted water gel explosive, the electric detonator 5 is the coal mine-permissible millisecond delay electric detonator, and the rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com