Electrochemical oxygen sensor packaging tool and package protection method

An oxygen sensor, electrochemical technology, applied in the direction of scientific instruments, instruments, measuring devices, etc., can solve the problems of electrolyte leakage, complicated welding process, high cost of pins, etc., achieve smooth surface, good heat dissipation performance, easy to solve oozing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

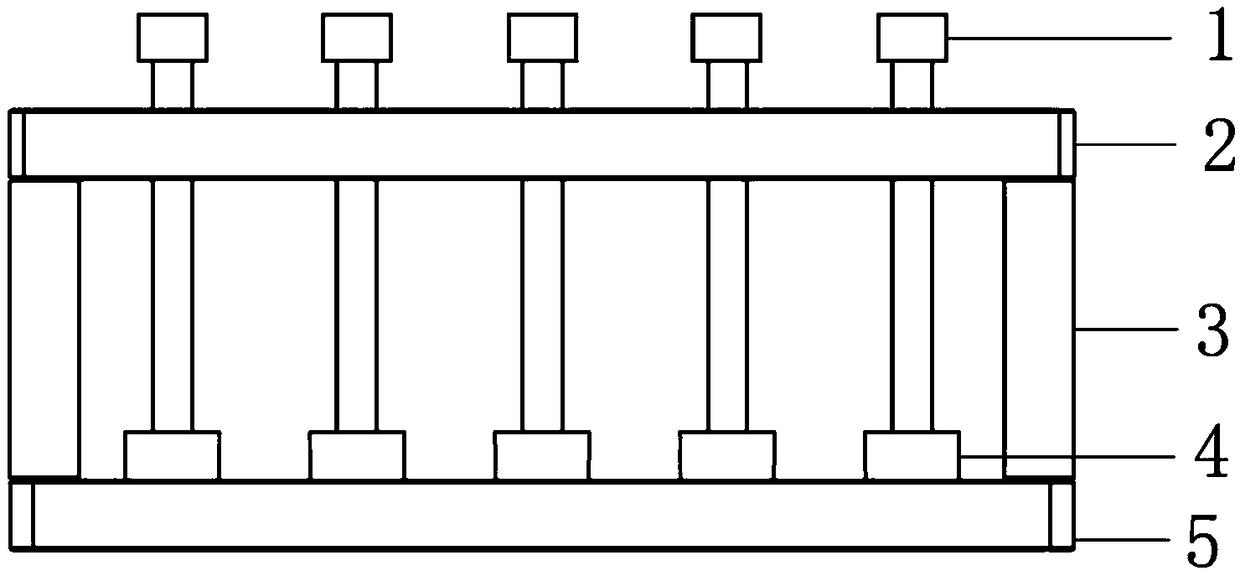

[0031] A tool for the packaging of electrochemical oxygen sensors, such as figure 1 As shown, the fixture includes a fixture body, a sensor fixing chamber 4 and an inner hexagonal screw 1; wherein, the fixture body is a box-like structure hollowed out in the middle, and the surface of the fixture upper cover 2 is provided with a threaded perforation , the bottom 5 of the tool is fixed with a sensor fixing chamber 4 and corresponds to the perforation position, and its two ends are provided with a tool fixing rod 3, which is used to connect and fix the upper cover 2 of the tool and the bottom 5 of the tool; the hexagon socket screw 1 can be pressed into the sensor fixing chamber 4 through the perforation of the upper cover 2 of the tool.

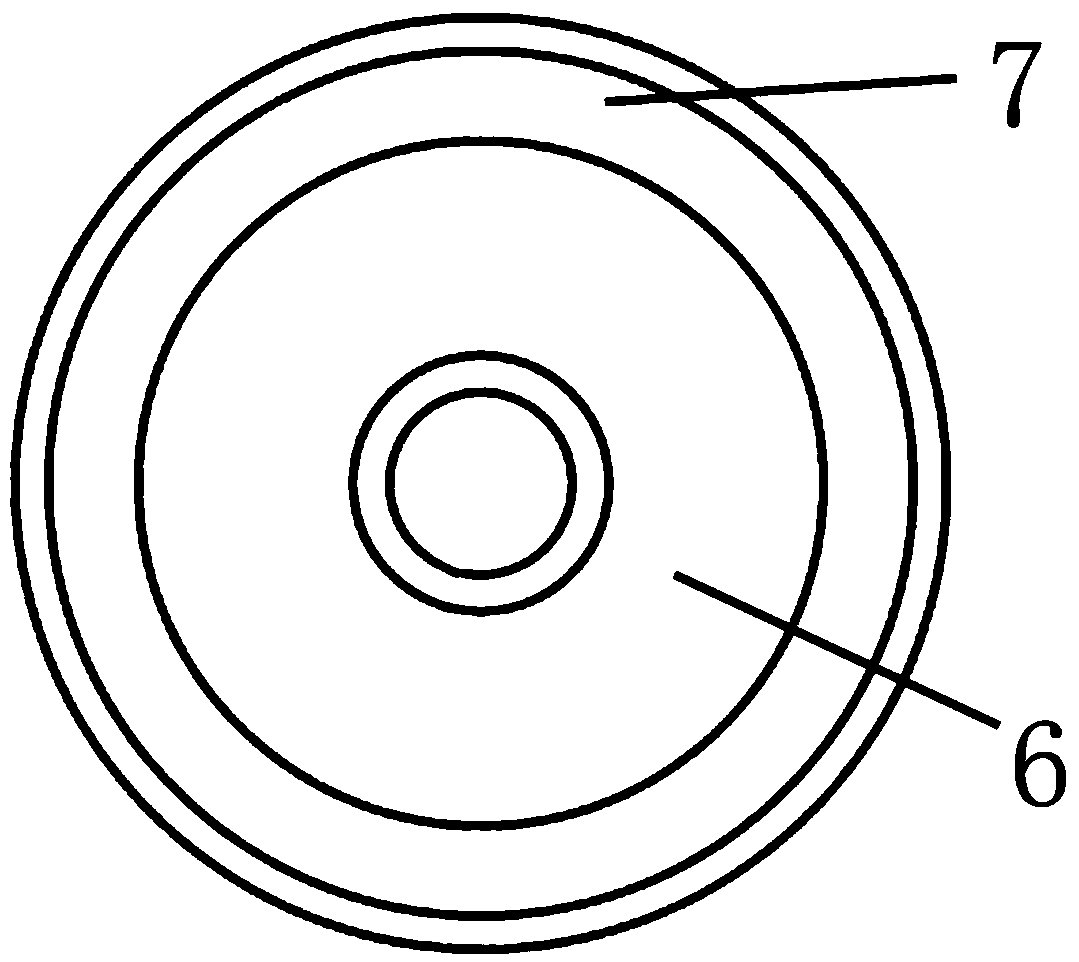

[0032] like figure 2 As shown, the upper cover of the electrochemical oxygen sensor is circular, and its center is located in a small groove at the center of the highest raised surface 6, and a sealing groove 7 is provided around its edge. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com