A new method of chemical process quality prediction

A chemical process and quality prediction technology, applied in the field of automation, can solve problems such as inability to deal with nonlinear processes and high modeling complexity, and achieve the effects of improving interpretation ability, strengthening prediction performance, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

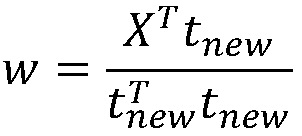

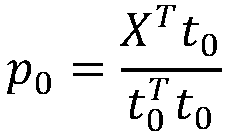

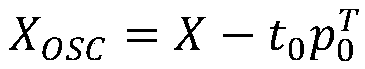

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with embodiment.

[0054] Take the Tennessee-Eastman process as an example:

[0055] The Tennessee-Eastman process consists of five parts: reactor, condenser, separator, compressor and stripper, and contains 12 operating variables and 41 measured variables. There are 21 failure variables.

[0056] Step 1. Collect sensor data in the chemical process, process it and establish a new process prediction model.

[0057] The specific steps are:

[0058] 1.1 The data in the chemical process is collected for offline modeling. The data is divided into two categories, process data X and quality data Y. There are a total of N samples.

[0059] X=[x 1 ,x 2 ,...x m ],x 1 ,x 2 …x m ∈R N×1

[0060] Y=[y 1 ,y 2 ,...y p ],y 1 ,y 2 ...y p ∈R N×1

[0061] where x 1 ,x 2 ,...x m etc. respectively represent the reactant concentration, pressure, temperature, valve opening and other variables in the Tenn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com