A water-cooled resistor with high voltage resistance

A water-cooled resistance and voltage technology, used in resistors, resistor parts, resistor shells/packaging shells/potting, etc., can solve problems such as unstable sealing, easy wear of porcelain tubes, and failure of resistance, and achieve good results. Good sealing effect and good sealing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

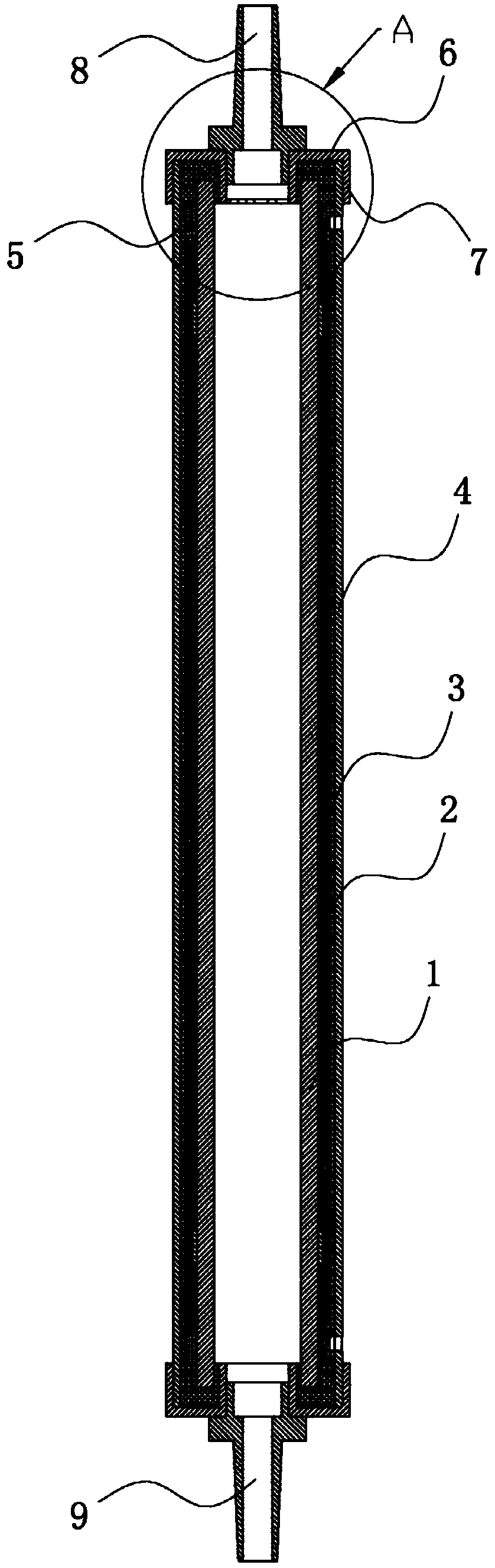

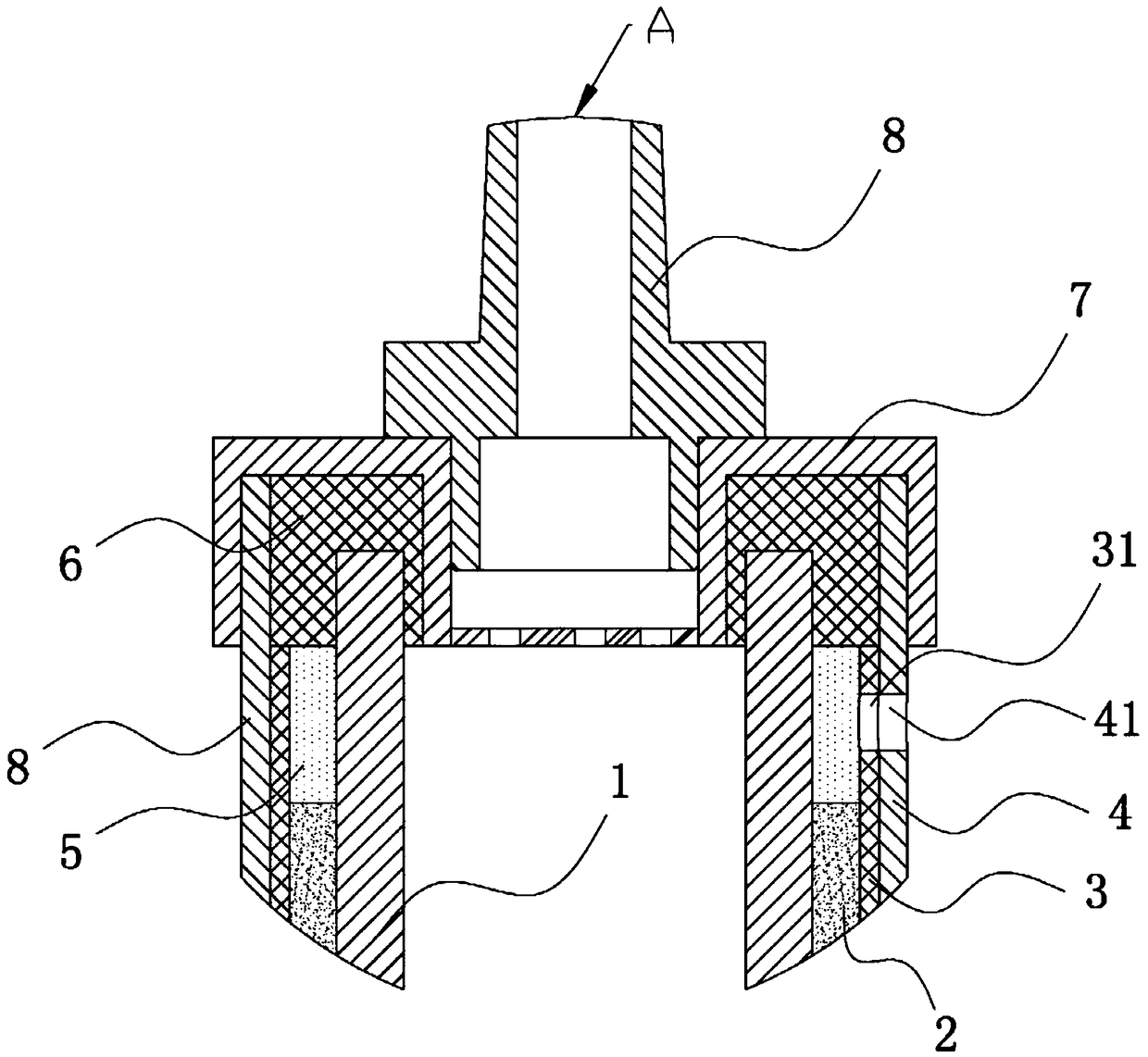

[0032] A water-cooled resistor with high voltage resistance in this embodiment, such as figure 1 and figure 2 As shown, it includes an alumina porcelain tube 1, the outer surface of the porcelain tube 1 is wound with a resistance wire not shown in the figure, and the outside of the porcelain tube 1 and the resistance wire is sequentially covered with a quartz sand material layer 2 (ie, a filler layer), a mica sleeve Tube 3 (that is, insulating sleeve) and metal tube 4, so that the resistance wire is isolated from the atmosphere, and it will not break down under high voltage conditions, which meets the requirements of high-voltage use environments, and the resistance wire is not easy to be oxidized, improving service life. Both ends of the metal tube 4 have outlet holes 41, the mica sleeve 3 has transition holes 31 aligned with the outlet holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com