Bipolar plate and preparation process thereof, single cell and proton exchange membrane fuel cell

A technology of proton exchange membrane and preparation process, which is applied in the field of fuel cells, can solve problems such as drainage restrictions, achieve the effects of preventing electrode flooding, facilitating industrial development, and improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

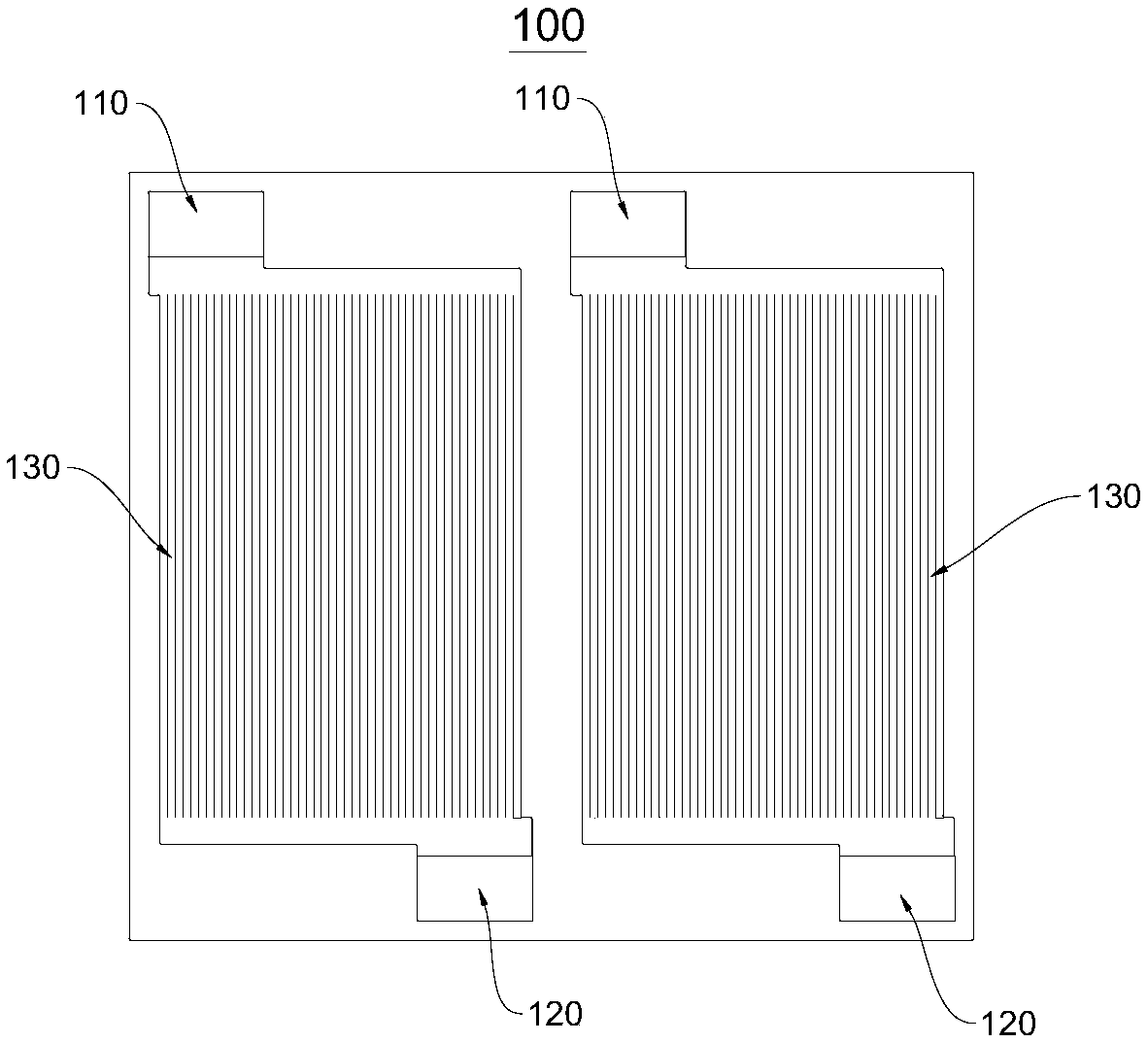

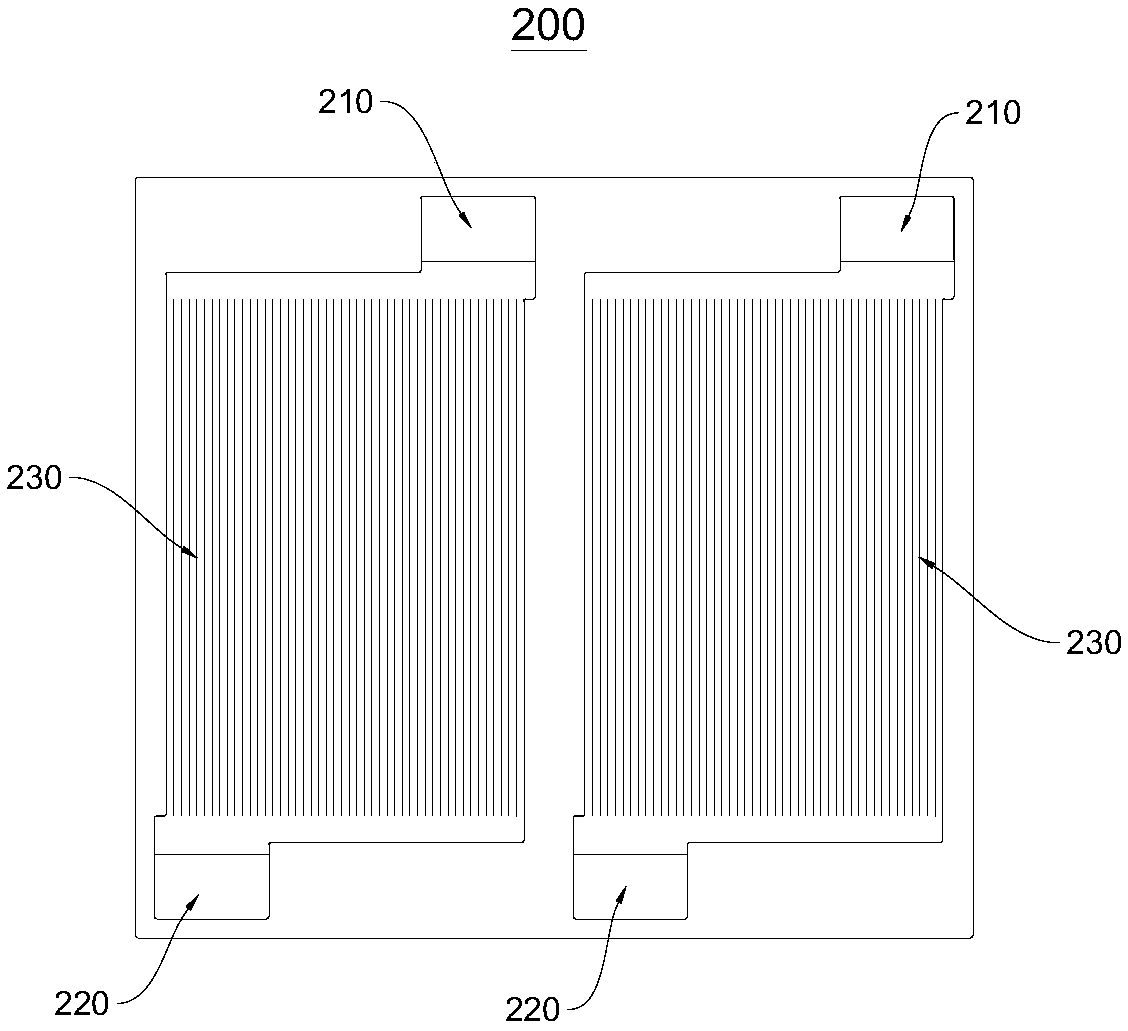

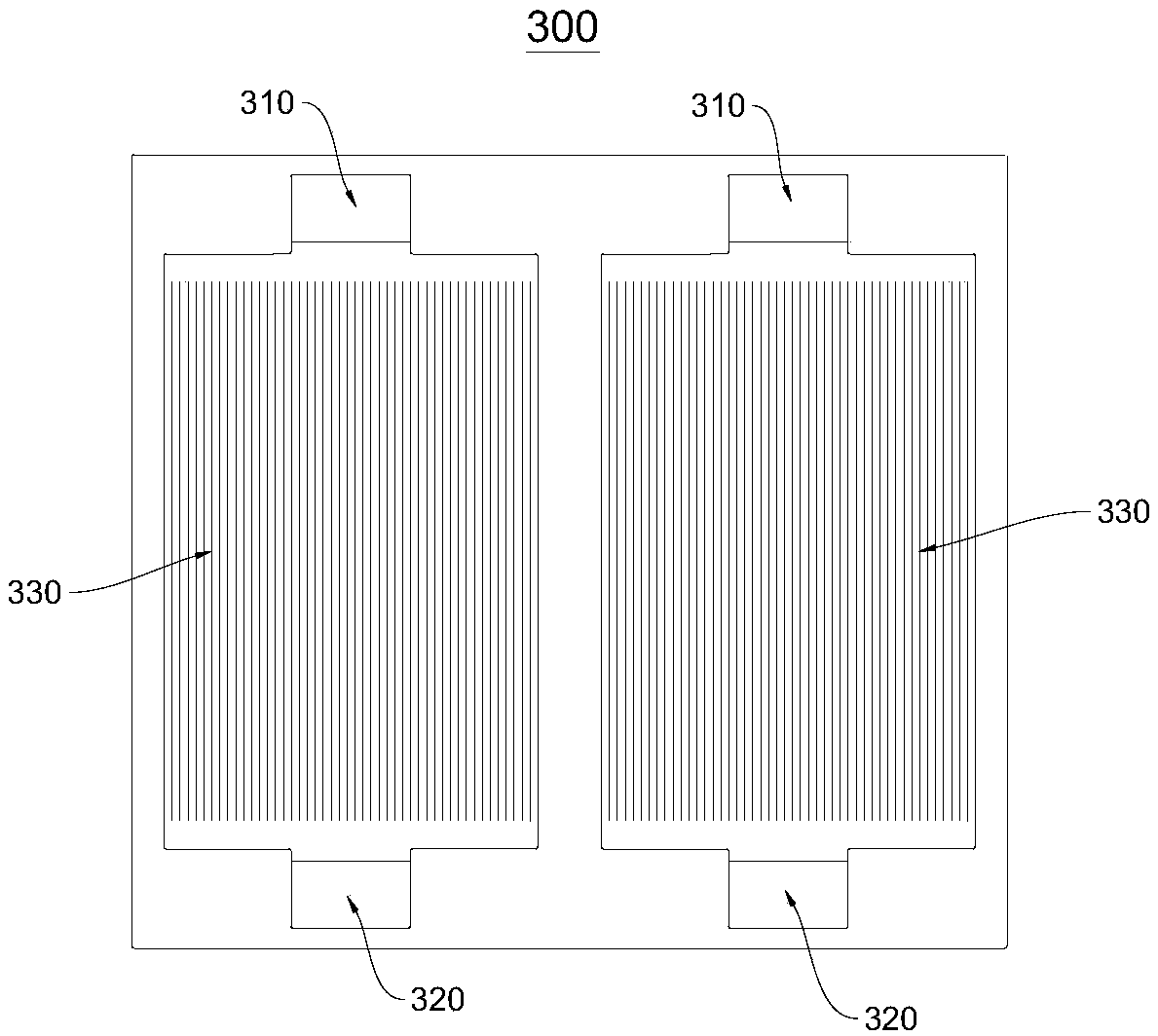

[0087] see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a bipolar plate and a manufacturing process thereof.

[0088] The bipolar plate includes a cathode plate 100 , an anode plate 200 and a cooling plate 300 .

[0089] The cathode plate 100, the anode plate 200 and the cooling plate 300 are all rectangular thin plates of titanium alloy with a thickness of 100 microns.

[0090] The cathode plate 100 is respectively provided with two oxidant inlets 110 and two oxidant outlets 120 , and the two oxidant inlets 110 and two oxidant outlets 120 are communicated with each other by an oxidant flow channel 130 . The cathode plate 100 includes two cathode structural units.

[0091] The anode plate 200 is respectively provided with two fuel gas inlets 210 and two fuel gas outlets 220 , and the two fuel gas inlets 210 and the two fuel gas outlets 220 are communicated by a fuel gas channel 230 correspondingly. The anode plate 200 includes two a...

Embodiment 2

[0097] see Figure 4 , see figure 1 and figure 2 , the embodiment of the present invention provides a bipolar plate and a manufacturing process thereof.

[0098] The bipolar plate includes a cathode plate 100 , an anode plate 200 and a cooling plate 300 .

[0099] The cathode plate 100, the anode plate 200 and the cooling plate 300 are all rectangular thin plates of titanium alloy with a thickness of 100 microns.

[0100] The cathode plate 100 is respectively provided with three oxidant inlets 110 and three oxidant outlets 120 , and the three oxidant inlets 110 and three oxidant outlets 120 are communicated with each other by the oxidant flow channels 130 . The cathode plate 100 includes three cathode structural units.

[0101] The anode plate 200 is respectively provided with three fuel gas inlets 210 and three fuel gas outlets 220 , and the three fuel gas inlets 210 and three fuel gas outlets 220 are communicated with each other by a fuel gas flow channel 230 . The ano...

Embodiment 3

[0107] see Figure 5 , the embodiment of the present invention provides a bipolar plate and a manufacturing process thereof.

[0108] The bipolar plate includes a cathode plate 100 , an anode plate 200 and a cooling plate 300 .

[0109] The cathode plate 100, the anode plate 200 and the cooling plate 300 are all rectangular thin plates of titanium alloy with a thickness of 100 microns.

[0110] The cathode plate 100 is respectively provided with four oxidant inlets 110 and four oxidant outlets 120 , and the four oxidant inlets 110 and four oxidant outlets 120 are communicated with each other by oxidant flow channels 130 . The cathode plate 100 includes four cathode structural units.

[0111] The anode plate 200 is respectively provided with four fuel gas inlets 210 and four fuel gas outlets 220 , and the four fuel gas inlets 210 and the four fuel gas outlets 220 are communicated one by one by the fuel gas flow channels 230 . The anode plate 200 includes four anode structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com