Loudspeaker magnet peeling assembly machine

A loudspeaker and assembly machine technology, applied in the direction of sensors, electrical components, etc., can solve the problems of reduced efficiency, high enterprise cost, inconvenient operation, etc., and achieve the effects of improving production efficiency, saving enterprise cost, and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

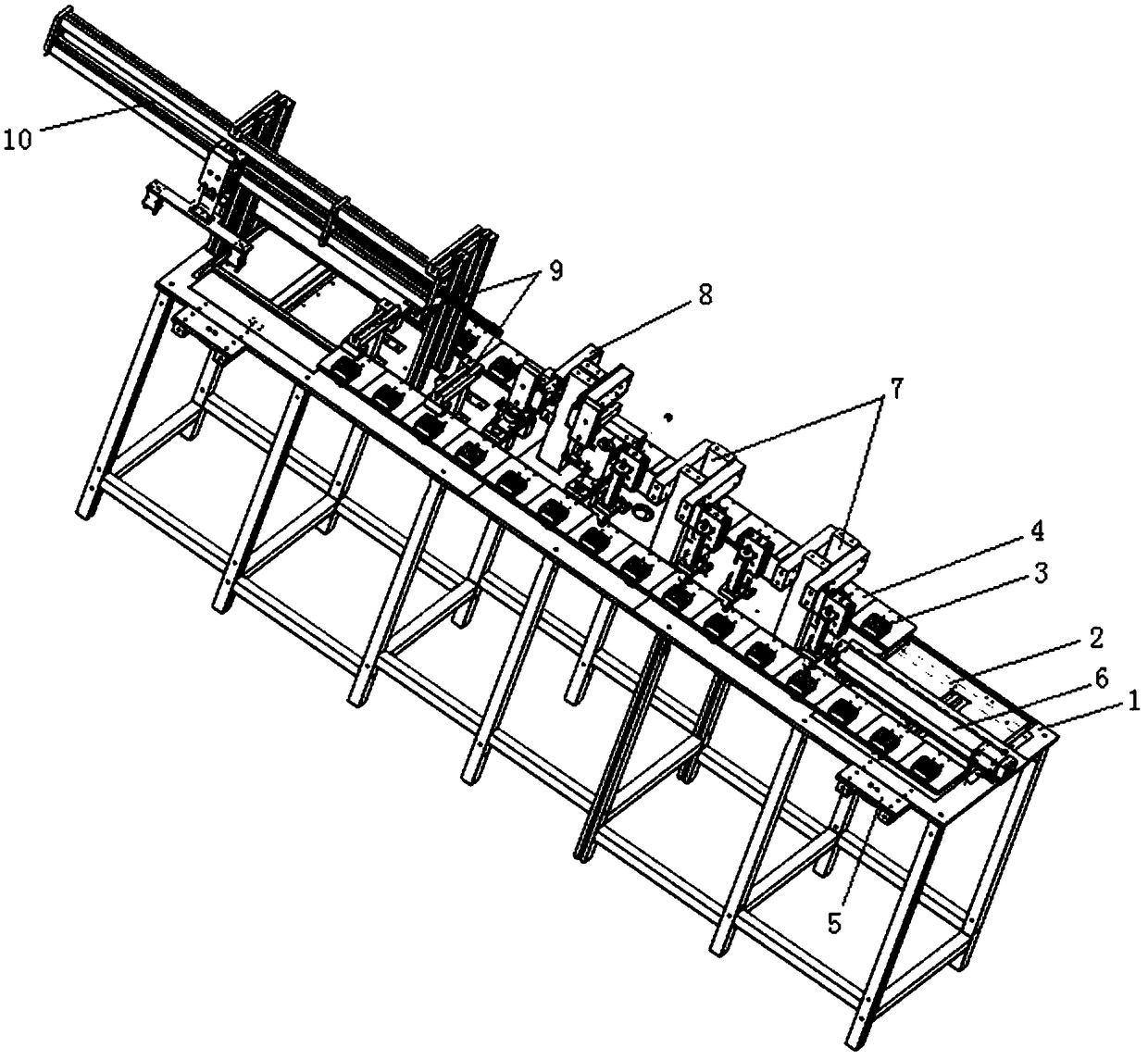

[0033] Loudspeaker magnet stripping assembly machines such as figure 1 As shown, the turntable 1 is included, and the turntable 1 is provided with a circulation process line 2 with a "back" shape structure. The circulation process line 2 is equipped with a number of bearing plates 4 for jigs 3, and the jigs 3 are used to place Speaker stand ready to be assembled.

[0034] The head end of the turntable 1 is provided with a transverse push assembly 5 along the transverse direction of the circulation process line 2, and a longitudinal push assembly 6 is provided along the longitudinal direction of the circulation process line 2. The transverse push assembly 5 and the longitudinal push assembly 6 are used to push each jig 3 Move to the next process position.

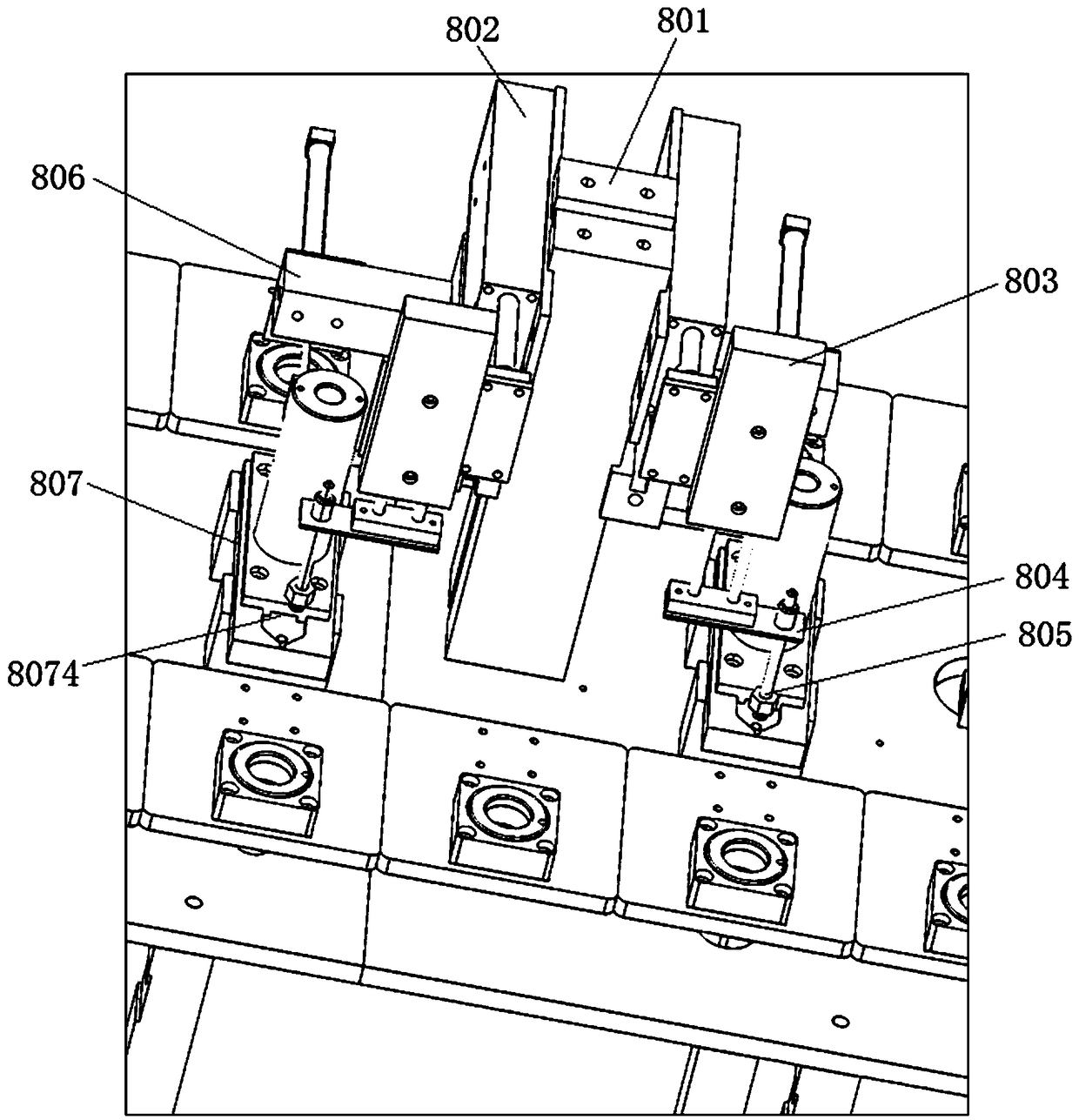

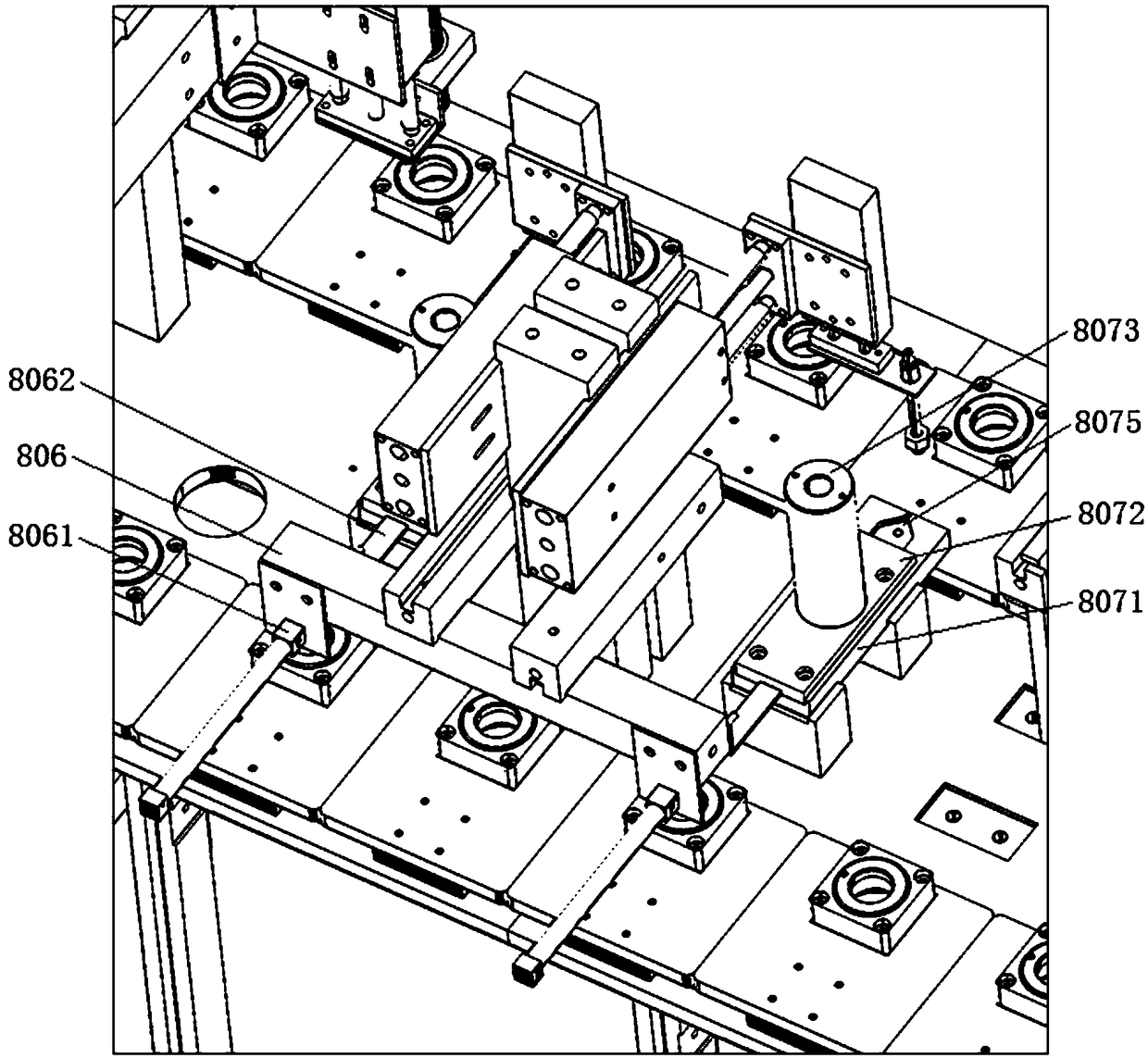

[0035] like Image 6 As shown, the horizontal pushing assembly 5 is arranged on the bottom side of the turntable 1 , and the horizontal pushing assembly 5 includes a first horizontal cylinder 501 , and a guide module 502 i...

Embodiment 2

[0045] The overall working process of the speaker assembly automatic assembly machine is as follows:

[0046] Place the loudspeaker bracket to be assembled on the jig 3, and transport the loudspeaker bracket to be assembled to the circulation process line 2 with a "back" structure through the conveyor belt. The jig 3 moves longitudinally through the vertical push component 6, and the horizontal push component 5 drives The guide module 502 moves laterally, thereby driving the jig 3 to move laterally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com