Robot production line used for extracting fish brain

A robot and assembly line technology, applied in fish processing, slaughtering, food science, etc., can solve the problems of low production efficiency, unsafety, affecting fish appearance and quality, and achieve the effect of simple structure, reliable feeding process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

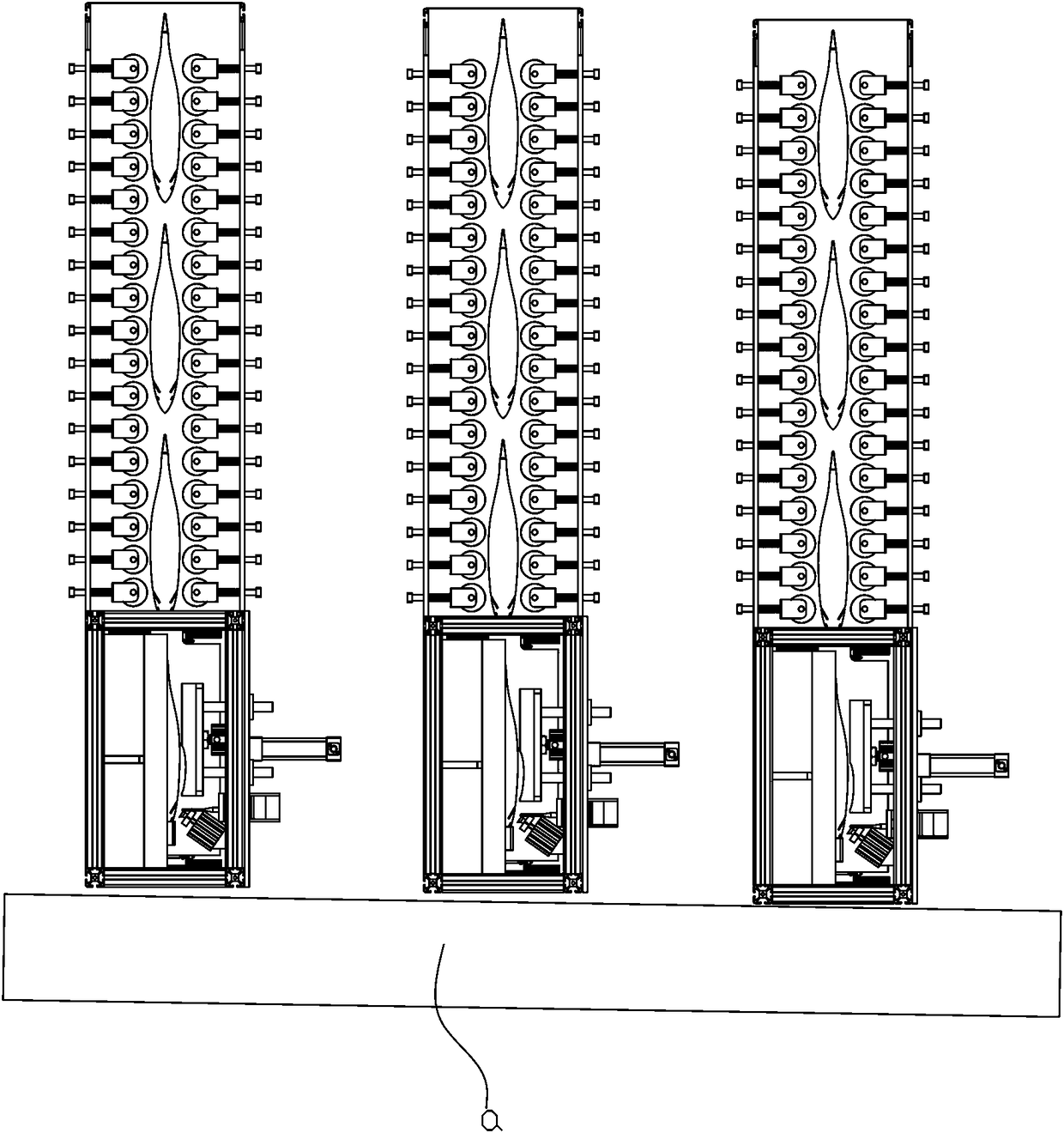

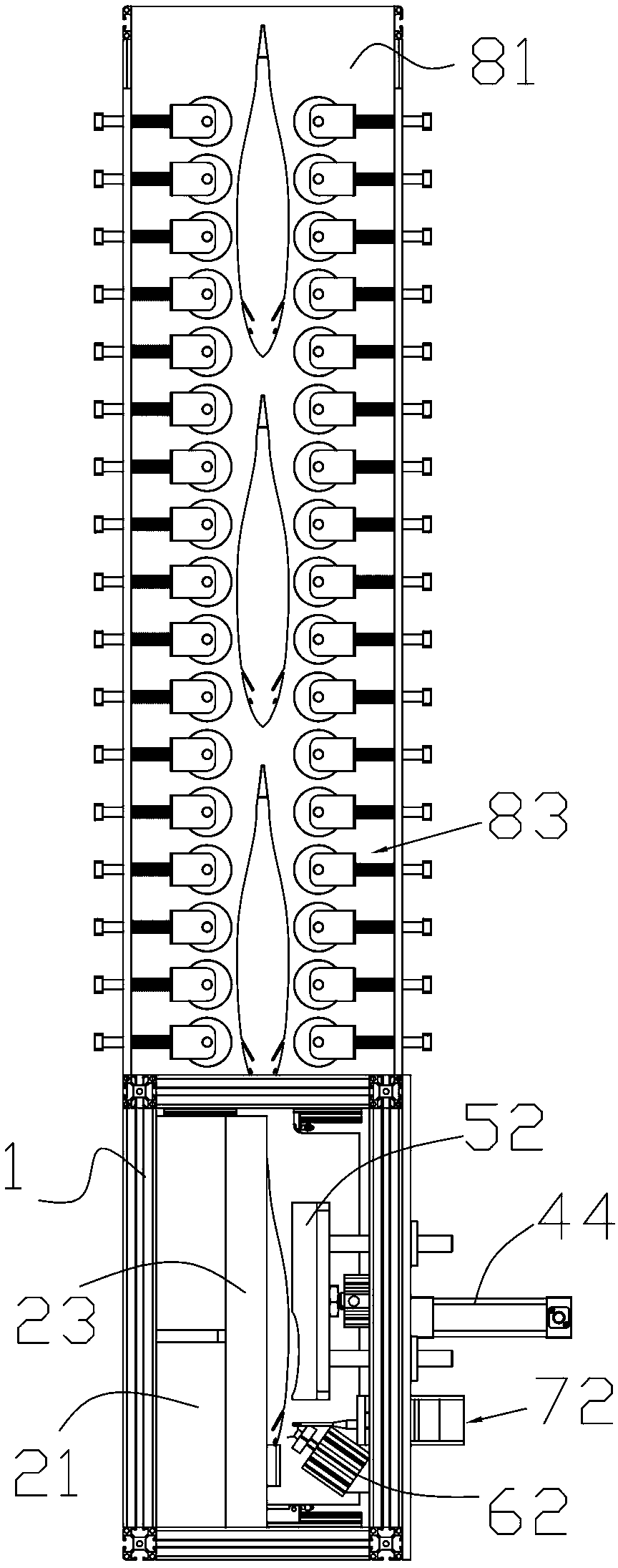

[0024] like Figure 1 to Figure 11 As shown, a robot assembly line for extracting fish brains described in this embodiment includes at least two fish brain extraction machines arranged side by side, all fish brain extraction machines are set in the same direction, and all fish brain extraction machines are set on the same side There is a conveyor belt a for retrieving fish.

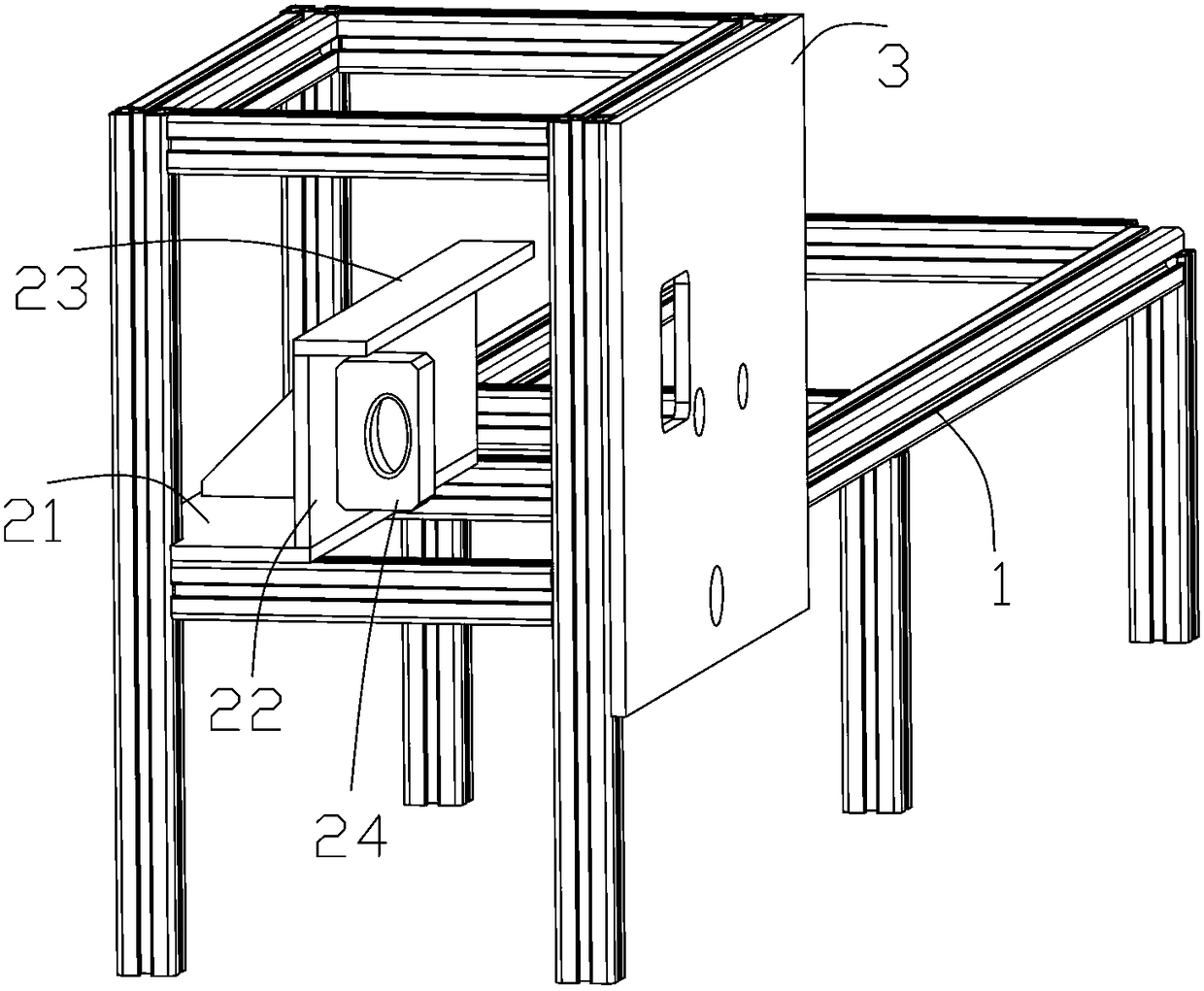

[0025]Described fish brain taking-out machine comprises frame 1 and material blocking seat, and described material blocking seat is fixed on the frame 1, and described material blocking seat comprises left bottom plate 21, left baffle plate 22 and upper baffle plate 23, and described left Base plate 21 is arranged on the frame 1, and described left baffle plate 22 is vertically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com