Cabinet with s-shaped aerosol fire extinguisher

An aerosol fire extinguisher and fire extinguishing mechanism technology, applied in fire rescue and other directions, can solve the problems of slow fire extinguishing speed, large volume of fire extinguisher, large internal space and other problems, achieve the effect of no ozone layer loss, wide application range, and avoid secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

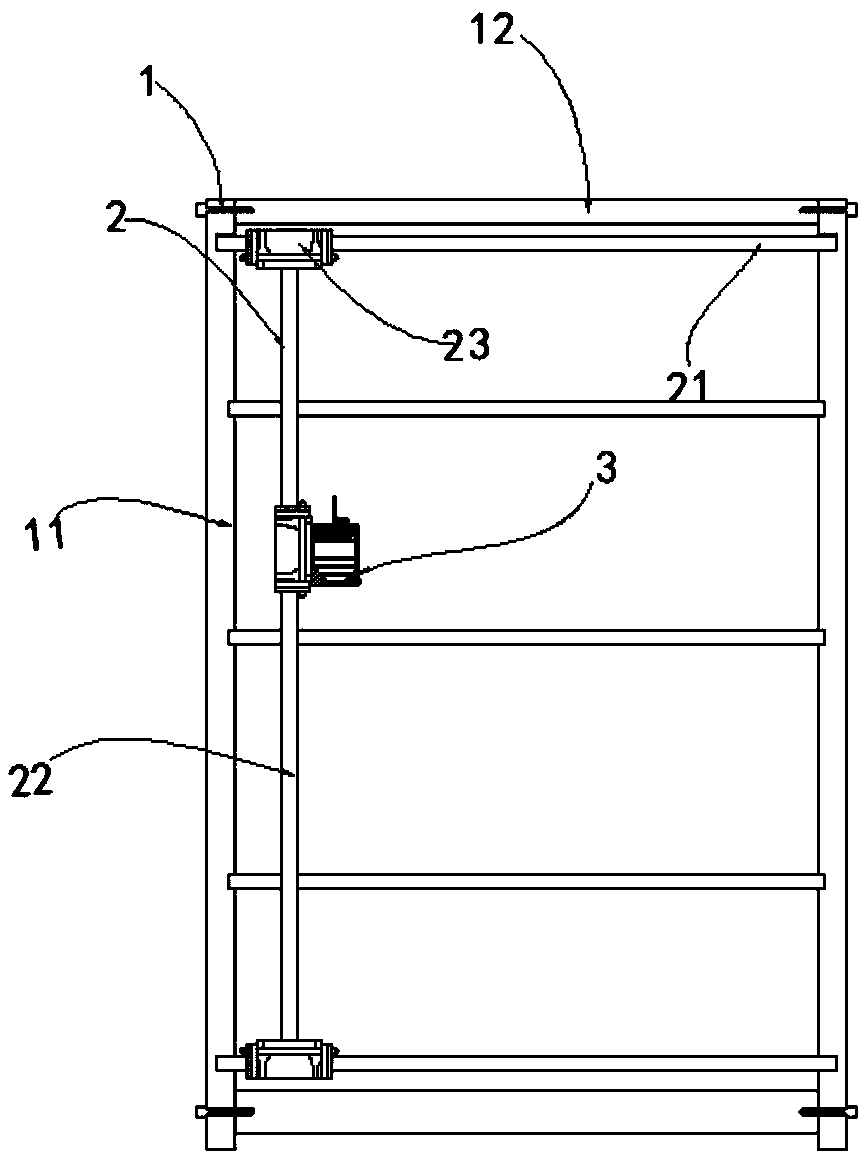

[0024] A cabinet 1 with an S-type aerosol fire extinguisher, including a cabinet 1, is characterized in that it also includes a moving mechanism 2 and a miniature fire extinguishing mechanism 3, and the miniature fire extinguishing mechanism 3 is fixed on the moving mechanism 2 through buckles. The mechanism 2 is arranged inside the cabinet 1;

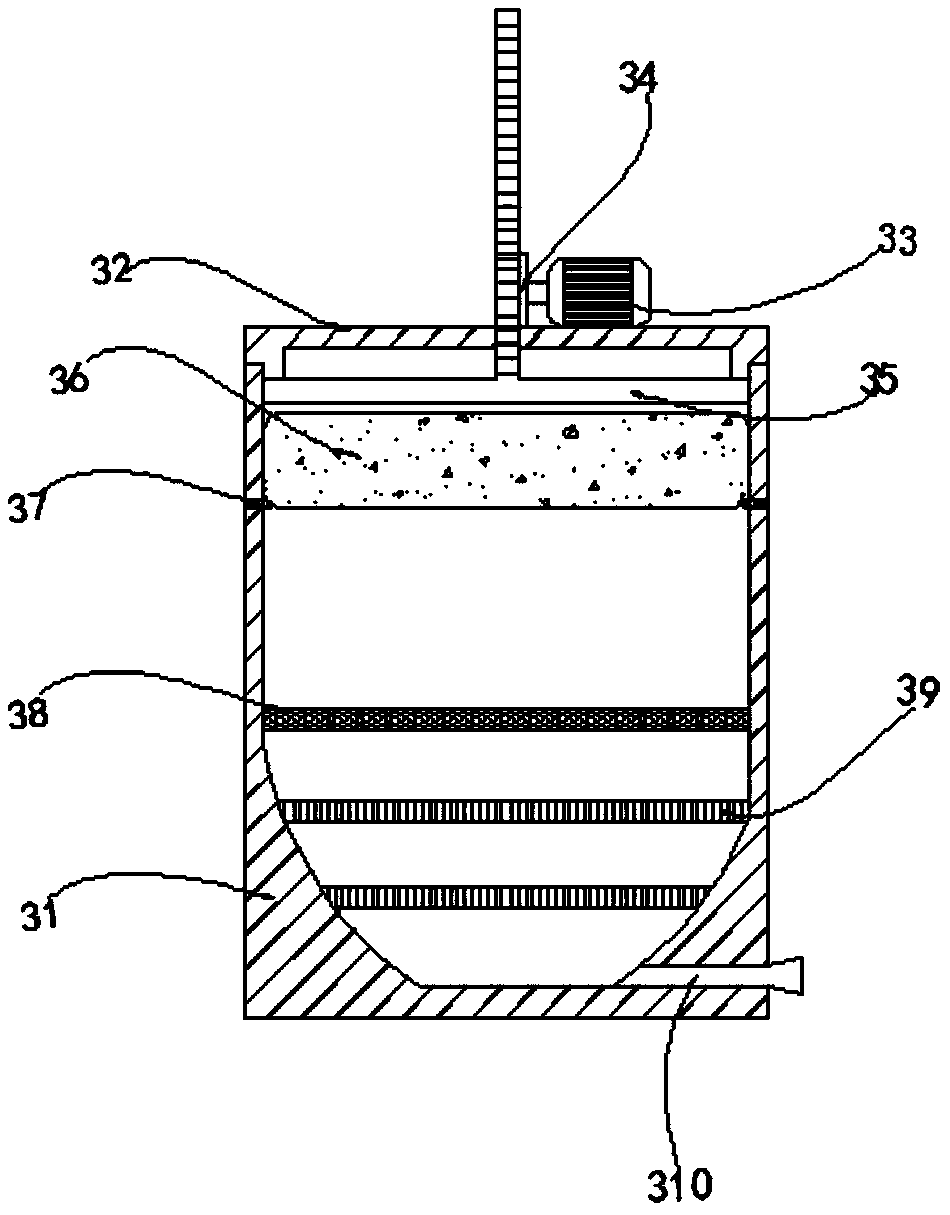

[0025] The miniature fire extinguishing mechanism 3 includes a housing 31, an airtight cover 32, a driving motor 33, a driving gear 34, a compression piston 35, a solid S-type aerosol fire extinguishing agent 36, a shrinkage fixing buckle 37, an electrolytic net 38, a cooling net 39, Spray pipe 310, the housing 31 is fixed on the slider 23 of the vertical rod 22 by buckling, the inner upper end of the housing 31 is provided with a screw thread that cooperates with the airtight cover 32, and the compression piston 35 passes through The through hole in the center of the airtight cover 32 and the upper end of the compression piston 35 are...

Embodiment 2

[0028] A cabinet 1 with an S-type aerosol fire extinguisher, including a cabinet 1, is characterized in that it also includes a moving mechanism 2 and a miniature fire extinguishing mechanism 3, and the miniature fire extinguishing mechanism 3 is fixed on the moving mechanism 2 through buckles. The mechanism 2 is arranged inside the cabinet 1 .

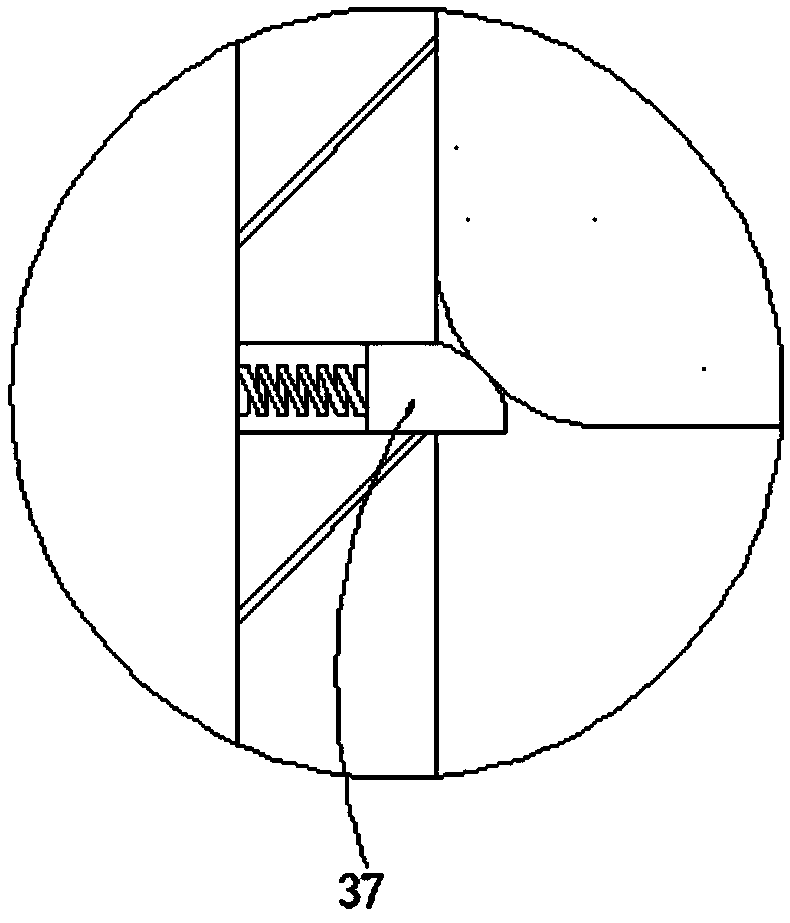

[0029] The specific shape of the electrolytic network 38 is honeycomb.

[0030] The working principle of this embodiment is as follows: when the solid S-type aerosol fire extinguishing agent 36 is electrolyzed to generate aerosol, the conventional method is to insert the electric starting rod into the solid S-type aerosol fire extinguishing agent 36, and then perform electrolysis. When the solid S-type aerosol fire extinguishing agent disintegrates into blocks during the electrolysis process, the contact area with the electric starting rod will decrease after becoming blocks, the electrolysis rate will decrease, and the speed of aeros...

Embodiment 3

[0032] A cabinet 1 with an S-type aerosol fire extinguisher, including a cabinet 1, is characterized in that it also includes a moving mechanism 2 and a miniature fire extinguishing mechanism 3, and the miniature fire extinguishing mechanism 3 is fixed on the moving mechanism 2 through buckles. The mechanism 2 is arranged inside the cabinet 1 .

[0033] The cooling net 39 is provided with upper and lower layers, and the interior of the cooling net 39 is filled with cooling liquid.

[0034]The working principle of this embodiment is as follows: Since the solid S-type aerosol fire extinguishing agent 36 needs to be electrolyzed to generate aerosol, it will release a large amount of heat. Damage to temperature-sensitive electronic components. However, the fire extinguishing mechanism designed by the present invention is small in size and is not suitable for common cooling structures. Therefore, the present invention is provided with a double-layer cooling net 39 at the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com