Wood product processing equipment

A technology for processing equipment and wood products, applied in the field of wood product processing equipment, can solve the problems of wood chip dispersion, inconvenient replacement, inconvenient protection and cleaning of wood chips, etc., and achieve the effect of ensuring processing quality and improving positioning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

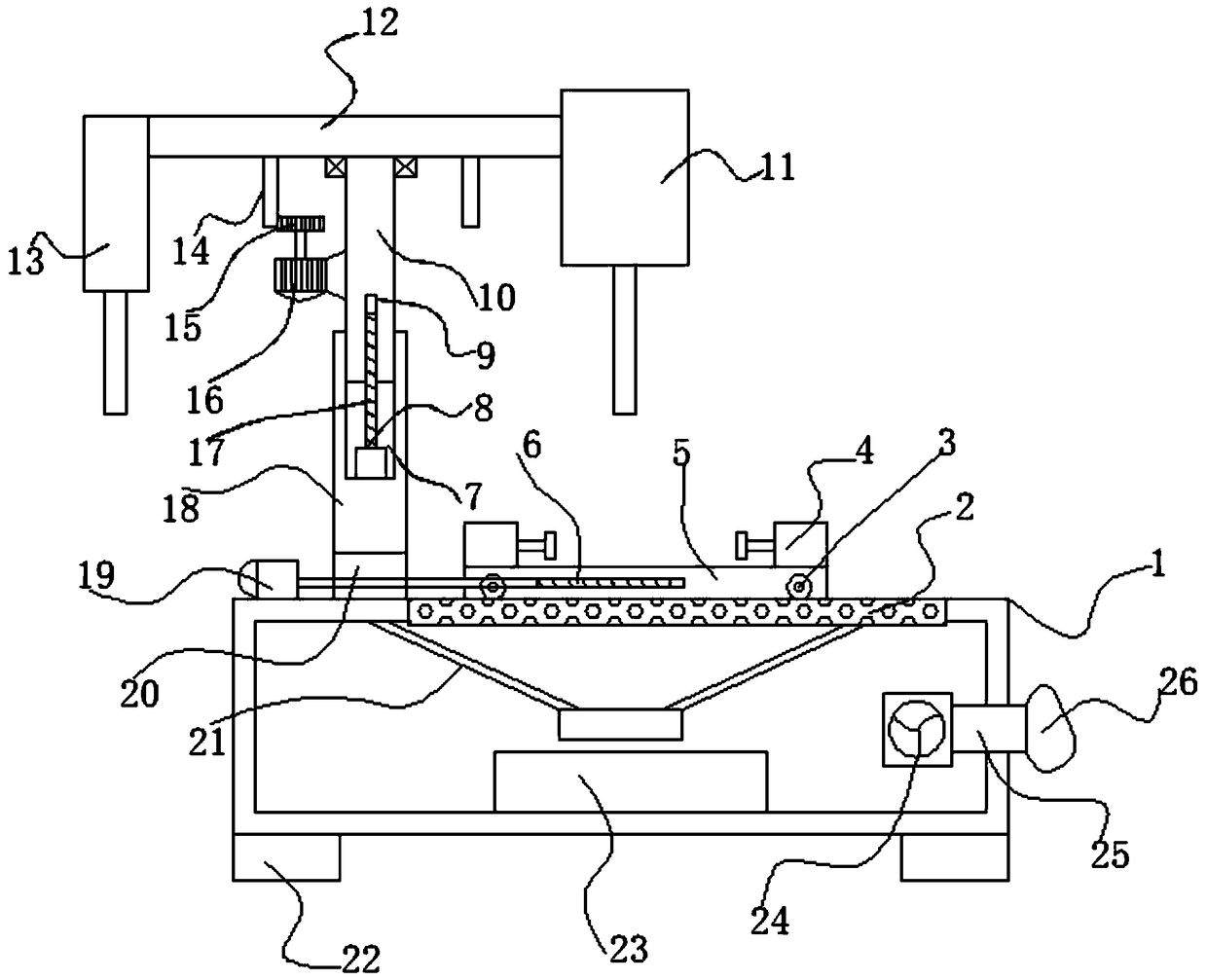

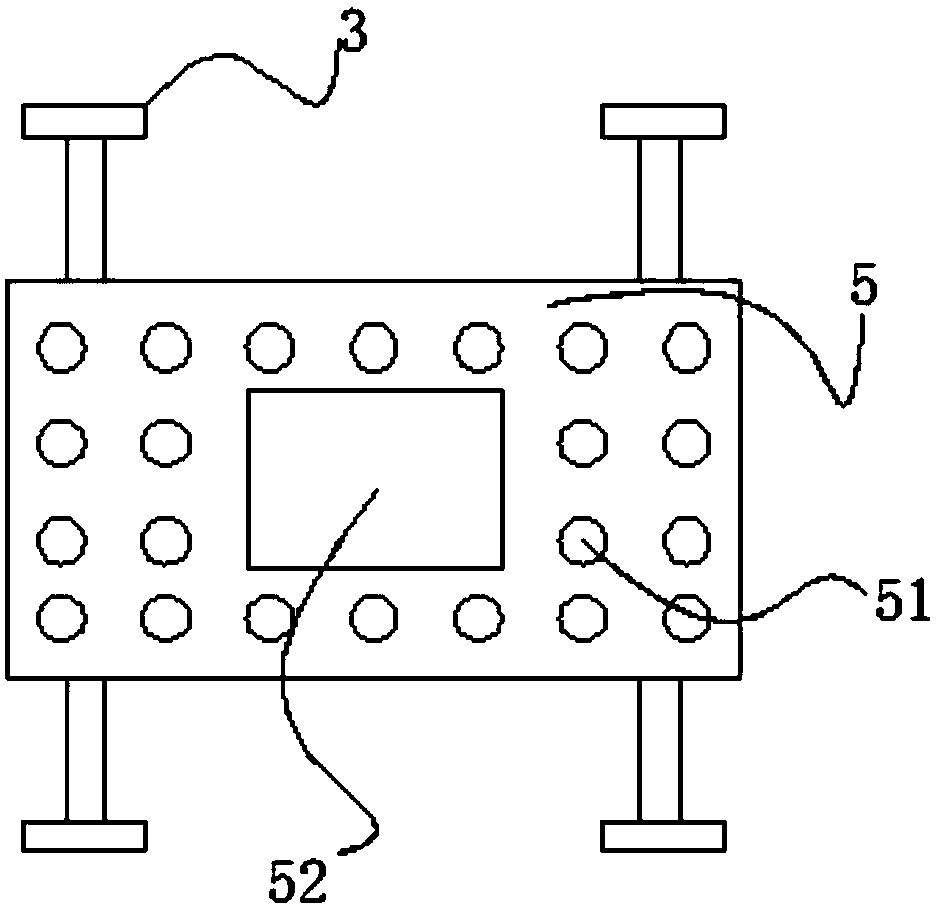

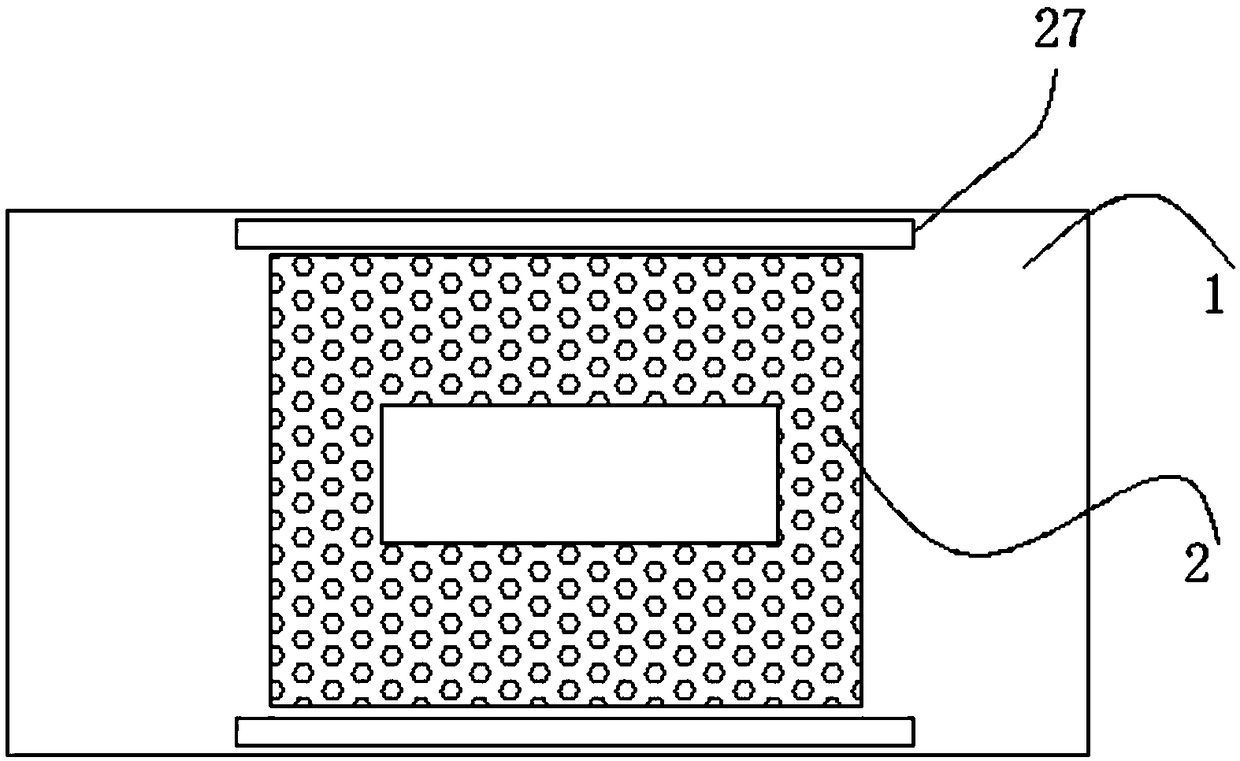

[0021] see Figure 1~3 , in the embodiment of the present invention, a wood product processing equipment includes a box body 1, and a support block 22 is respectively provided at the four corners of the bottom of the box body 1, and the support block 22 is a rubber block. 1 The upper left end is vertically fixed with a fixed column 18, the upper end of the fixed column 18 is provided with a lifting column 10, the top of the lifting column 10 is provided with a drilling mechanism, and the box body 1 on the right side of the fixed column 18 is provided with a sliding seat 5, the sliding seat 5 is provided with a pressing mechanism for fixing wood, the sliding seat 5 is connected to the left side of the box body 1 through a horizontal displacement mechanism, and the top of the box body 1 where the sliding seat 5 is located is provided with a negative pressure dust collection mechanism;

[0022] The negative pressure dust collection mechanism includes a ventilating grid 2 located ...

Embodiment 2

[0027] The difference from Embodiment 1 is that the drilling mechanism includes a suspension rod 12 that is rotatably arranged on the upper end of the lifting column 10, the left end of the suspension rod 12 is provided with a laser positioning head 13, and the right end of the suspension rod 12 is provided with a drill bit 11. A rotary drive mechanism is arranged between the column 10 and the suspension rod 12. The rotary drive mechanism includes a driven gear ring 14 positioned at the lower end of the suspension rod 12. A rotary motor 16 is fixed on the left side of the lifting column 10. The output end of the rotary motor 16 is provided with There is a driving gear 15. Driven by the rotating motor 16, the driving gear 15 drives the driven gear ring 14 to rotate, so that the gear ring 14 drives the suspension rod 12 to rotate, thereby realizing the switching of the positions of the drill bit 11 and the laser positioning head 13. When the laser positioning head 13 emits light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com