Method for making scanning electron microscope example for assembling nanometer line array in aluminum oxide template

A nanowire array and alumina template technology, which is applied in the preparation of test samples, circuits, discharge tubes, etc., can solve the problems affecting the observation of scanning electron microscope and blurring of scanning electron microscope photos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Fabrication of SEM samples of Te nanowire arrays in alumina templates

[0015] 1, adopt the inventive method to make the scanning electron microscope sample of Te nanowire array in the aluminum oxide template

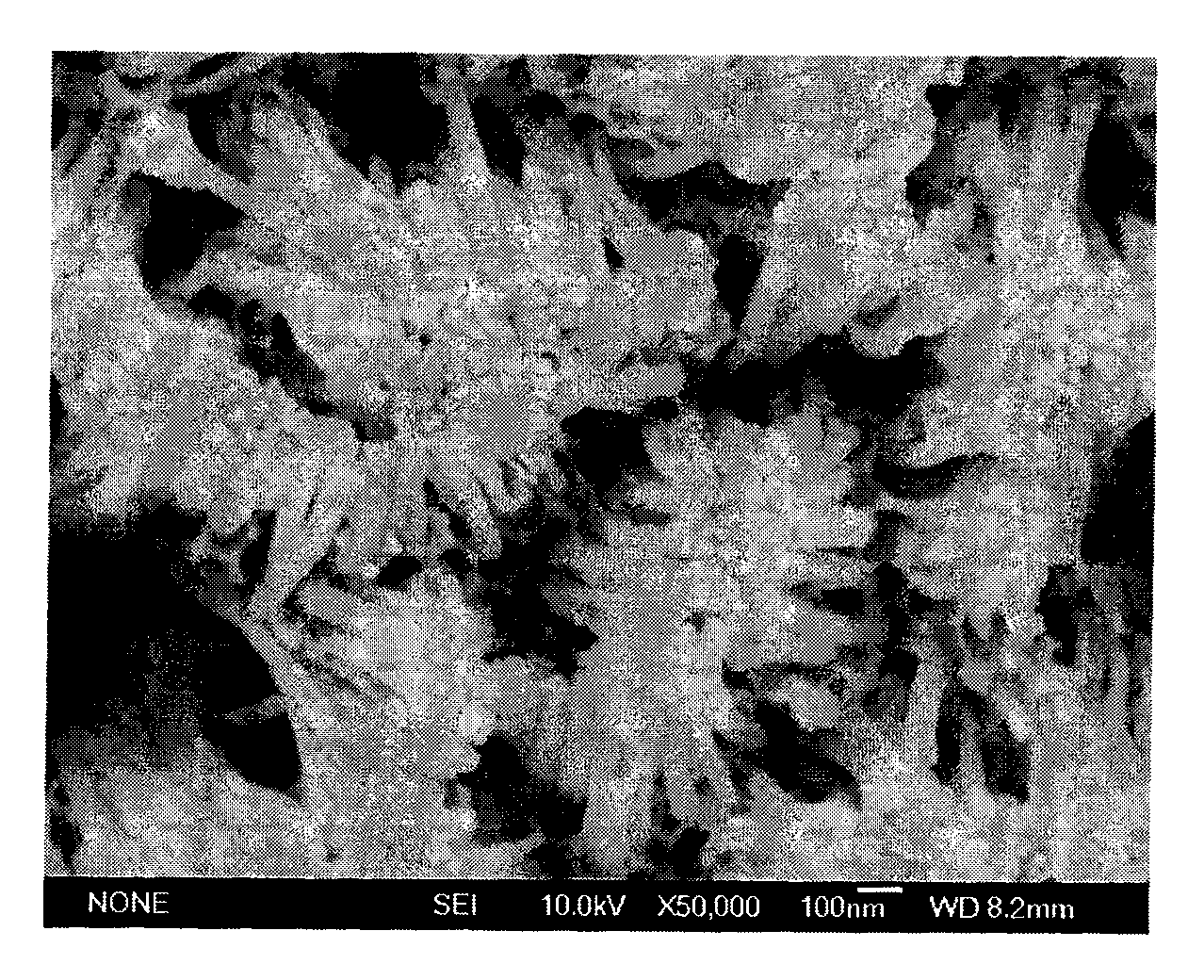

[0016] Take a piece of alumina template assembled with Te nanowire array, place it at the bottom of the beaker, use a dropper to take 0.1mL NaOH solution with a concentration of 1M and drop it in the middle of the template, after 5 minutes, inject 100mL NaOH solution with a concentration of 0.0001M After soaking for 15 minutes, the sample was taken out, washed several times with a large amount of water, dried and observed under a scanning electron microscope to obtain a scanning electron microscope photo of Te nanowire arrays treated by the method of the present invention. It can be seen from the scanning electron microscope photo in Figure 1 that the surface of the sample is smooth and clear, the holes of the template can be clearly seen, and no other...

Embodiment 2

[0019] Example 2: Ag in alumina template 2 Fabrication of SEM samples of Te nanowire arrays

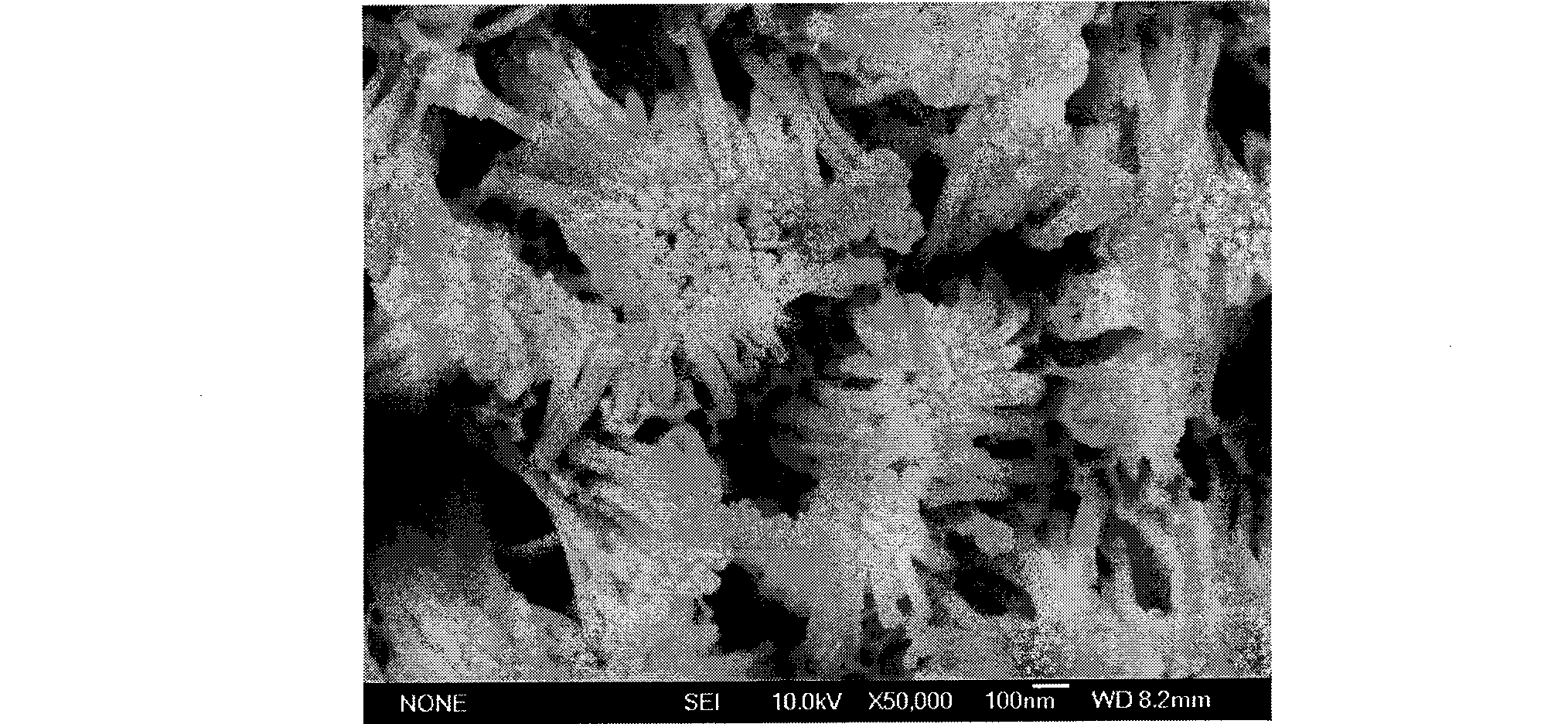

[0020] Take a piece assembled with Ag 2 Alumina template of Te nanowire array, place it at the bottom of the beaker, use a dropper to take 0.1mL of KOH solution with a concentration of 0.05M and drop it in the middle of the template, after 15 minutes, inject 20mL of KOH solution with a concentration of 0.0005M, soak for 15 After 10 minutes, take out the sample, wash repeatedly several times with a large amount of water, observe under the scanning electron microscope after drying, obtain the Ag after the inventive method process. 2 The scanning electron micrograph of Te nanowire array is shown in Fig. 3. It can be seen from the scanning electron microscope photo in Figure 3 that the surface of the sample is smooth and clear, and the details of the topography of the sample surface are not covered, and no other substances are found attached.

Embodiment 3

[0021] Example 3: Ag in alumina template 7 Te 4 Fabrication of SEM samples of nanowire arrays

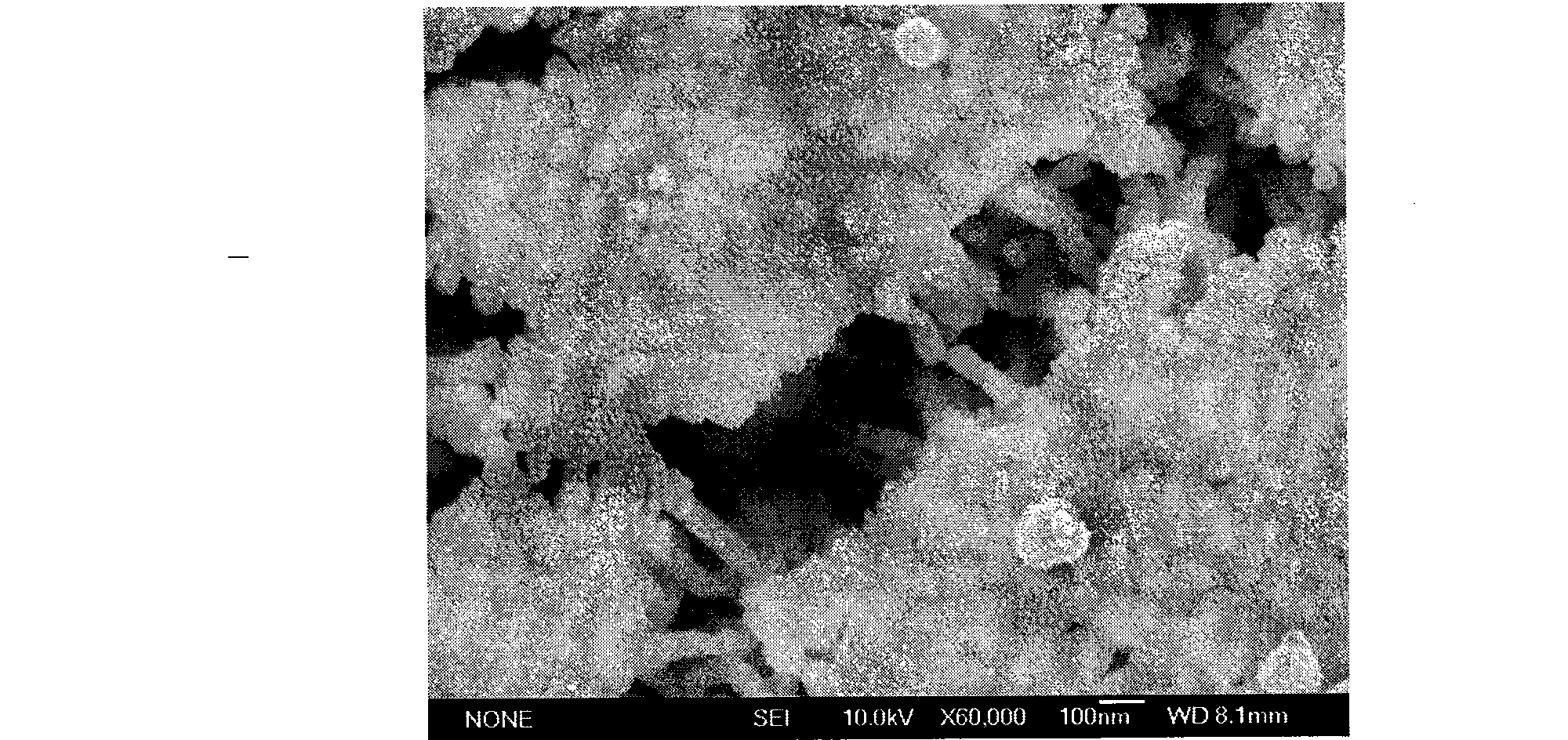

[0022] Take a piece assembled with Ag 7 Te 4 The aluminum oxide template of the nanowire array is placed at the bottom of the beaker, and 0.05mL of NaOH solution with a concentration of 5M is dropped in the middle of the template with a dropper. After 30 minutes, 100mL of KOH solution with a concentration of 0.0001M is injected and soaked for 30 minutes. , take out the sample, wash it several times with a large amount of water, dry it and observe it under a scanning electron microscope, and get Ag 7 Te 4 The scanning electron micrograph of the nanowire array is shown in Fig. 4. It can be seen from the scanning electron microscope photo in Figure 4 that the surface of the sample is smooth and clear, and the details of the morphology are not covered up, and no other substances are found attached.

[0023] in conclusion:

[0024] As can be seen from the above examples, the scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com