Backward sweep angle and upper/lower reflex angle directly controllable osculating cone waverider body design method

A design method and waverider technology, applied in the field of aerodynamic shape design of hypersonic aircraft, can solve problems such as inability to directly control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

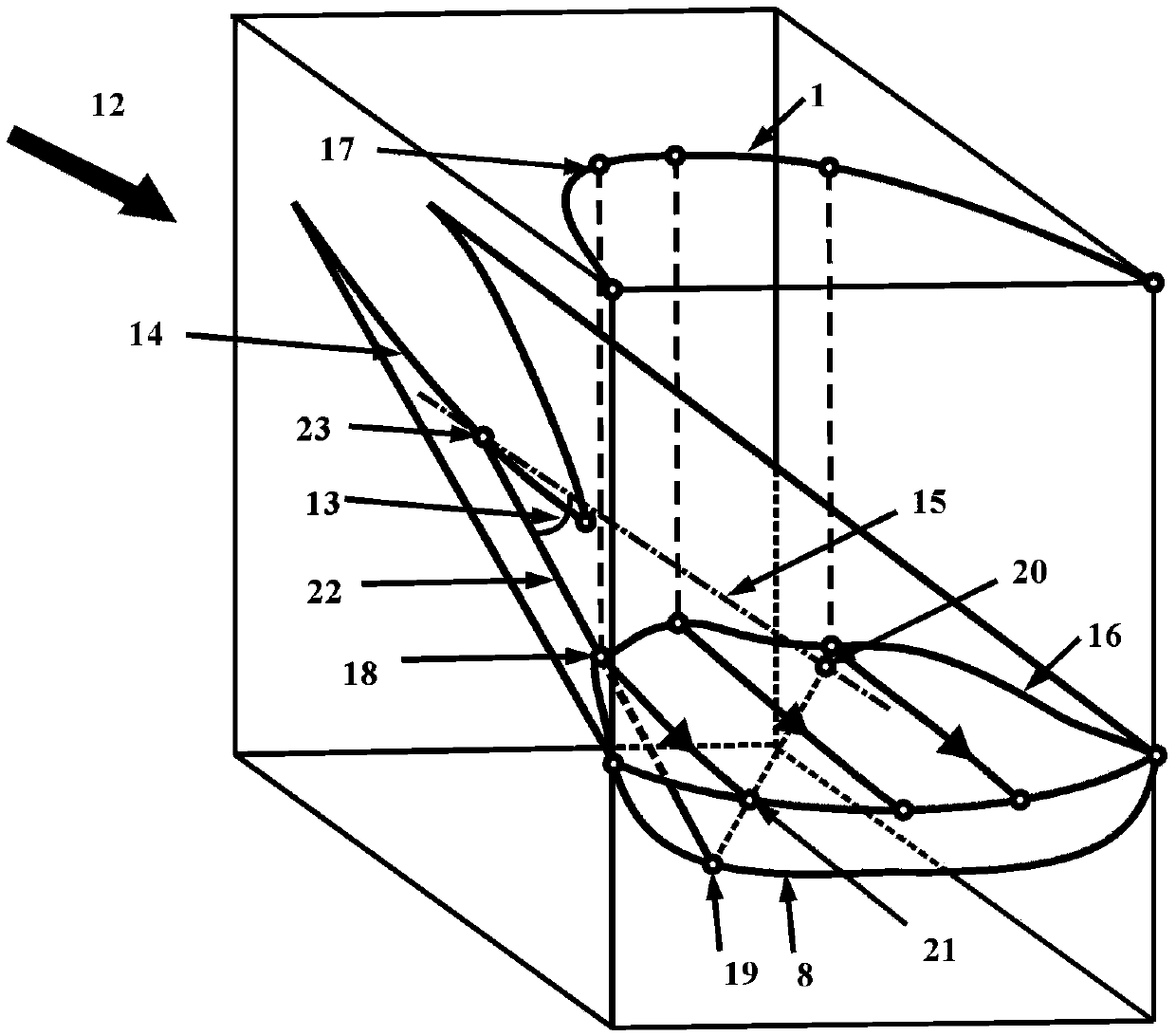

[0117] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in combination with the accompanying drawings in the embodiments of the present invention, and give further detailed descriptions, but the scope of protection of the present invention will not be limited accordingly.

[0118] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in combination with the accompanying drawings in the embodiments of the present invention, and give further detailed descriptions, but the scope of protection of the present invention will not be limited accordingly.

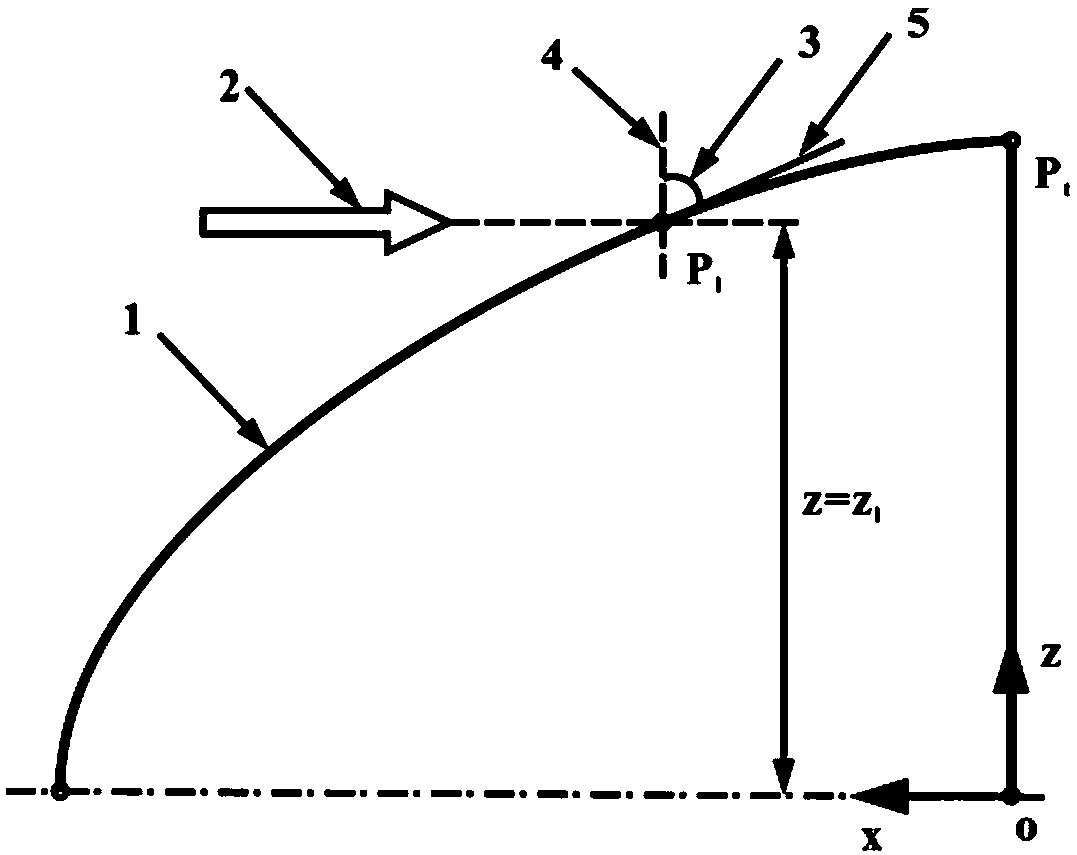

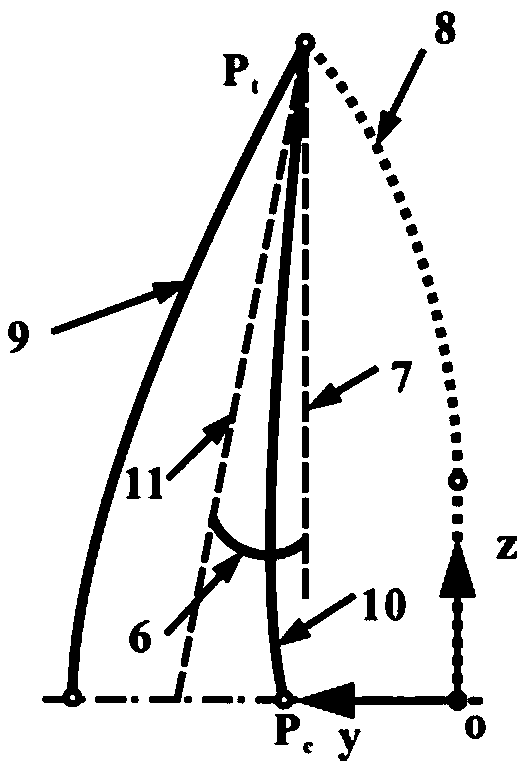

[0119] A method for designing a kiss-cut cone waverider with directly controllable sweep angle and dihedral angle, including the following steps:

[0120] S1: The reference flow field parameters are given, where the reference flow field parameters include incoming flow Mach number Ma and shock angle β...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap