High-transparency thermoplastic polyolefin elastomer adhesive film and application thereof

A diathermy, polyolefin technology, applied in the direction of film/sheet without carrier, adhesive, film/sheet adhesive, etc. Long lamination time and other problems, to achieve the effect of short lamination time, improve production efficiency and reduce thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First, use 96.8g of polyolefin elastomer particles, 0.2g of phenolic antioxidant, 0.1g of phosphite antioxidant, 0.1g of sulfide antioxidant, 2g of nano-silica, and 0.6g of polymeric silane coupling agent. g, 0.2 g of a light stabilizer was prepared to obtain a high-permeability thermoplastic polyolefin elastomer film (I).

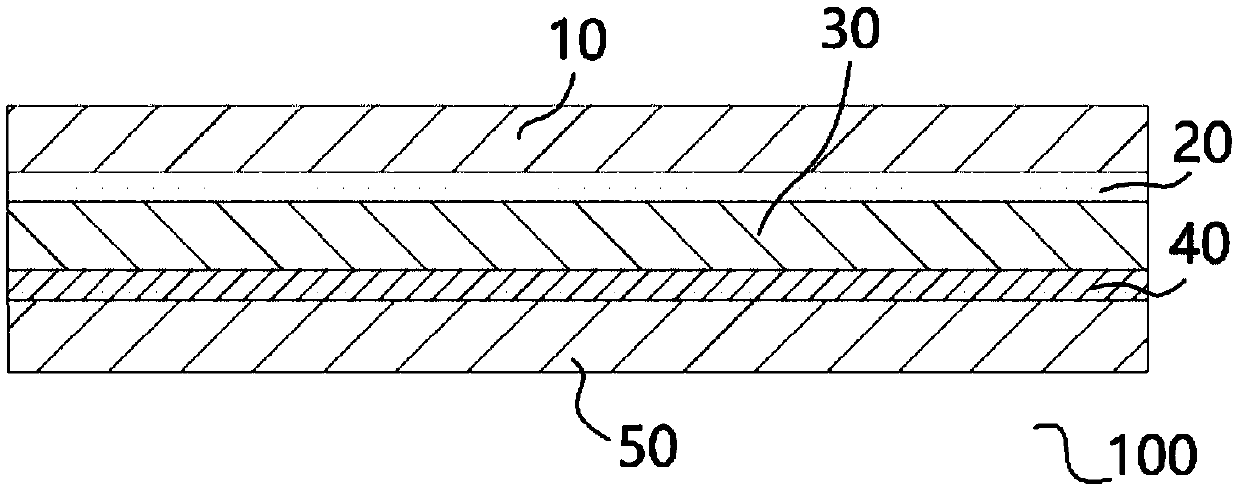

[0042] Then, the prepared high-permeable thermoplastic polyolefin elastomer film (I) was laminated at a temperature of 150° C. for 9 minutes, and after 500 hours of damp heat aging (double 85) test, its damp heat aging yellowing value was 1.2. After ultraviolet irradiation (60KWh), its ultraviolet aging yellowing value is 1.3, and the lamination peeling force between the high-permeability thermoplastic polyolefin elastomer film (I) and photovoltaic glass 10 can reach 155N / cm, and the obtained The high-permeability thermoplastic polyolefin elastomer film (I) has no air bubbles and the light transmittance can reach 89.9%.

Embodiment 2

[0044] First, use 96.1g of polyolefin elastomer particles, 0.1g of phenolic antioxidant, 0.1g of phosphite antioxidant, 0.1g of sulfide antioxidant, 3g of nano-silica, and 0.5g of polymeric silane coupling agent. g, 0.1 g of a light stabilizer to prepare a high-permeability thermoplastic polyolefin elastomer film (II).

[0045] Then, the prepared high-permeable thermoplastic polyolefin elastomer film (II) was laminated at 150°C for 7 minutes, and tested for 500 hours by damp heat aging (double 85), the yellowing value of damp heat aging was 1.0, and after ultraviolet After irradiation (60KWh), the UV aging yellowing value is 1.2, and the lamination peeling force between the high-permeability thermoplastic polyolefin elastomer film (II) and photovoltaic glass 10 is 150N / cm. The plastic polyolefin elastomer film (II) has no air bubbles and the light transmittance can reach 89.8%.

Embodiment 3

[0047] First, use 97.0g of polyolefin elastomer colloid, 0.3g of phenolic antioxidant, 0.4g of phosphite antioxidant, 0.2g of sulfide antioxidant, 1g of nano-silica, and 0.6g of polymeric silane coupling agent. g, 0.3 g of light stabilizer to prepare a high-permeability thermoplastic polyolefin elastomer film (Ⅲ).

[0048] Then, the prepared high-permeable thermoplastic polyolefin elastomer film (Ⅲ) was laminated at a temperature of 150°C for 8 minutes, and tested for 500 hours by damp heat aging (double 85), the yellowing value of damp heat aging was 0.9, and after ultraviolet After irradiation (60KWh), the UV aging yellowing value is 1.1, and the lamination peeling force between the high-permeability thermoplastic polyolefin elastomer film (II) and the photovoltaic glass 10 is 158N / cm, and the obtained high heat-permeability The plastic polyolefin elastomer film (II) has no air bubbles and the light transmittance can reach 90.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com