White packaging adhesive film for solar cell module

A solar cell and encapsulation adhesive film technology, applied in the field of solar cells, can solve problems such as poor heat and humidity resistance, easy decomposition, yellowing, delamination, etc., achieve excellent low-temperature impact resistance, solve the problem of easy overflow, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

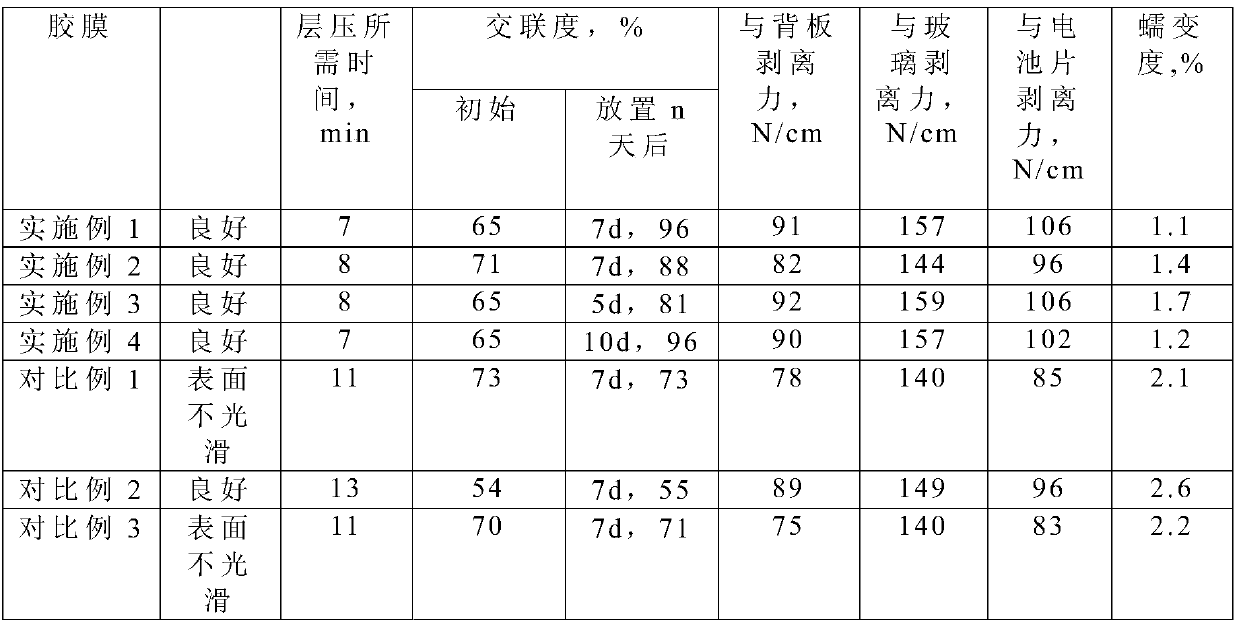

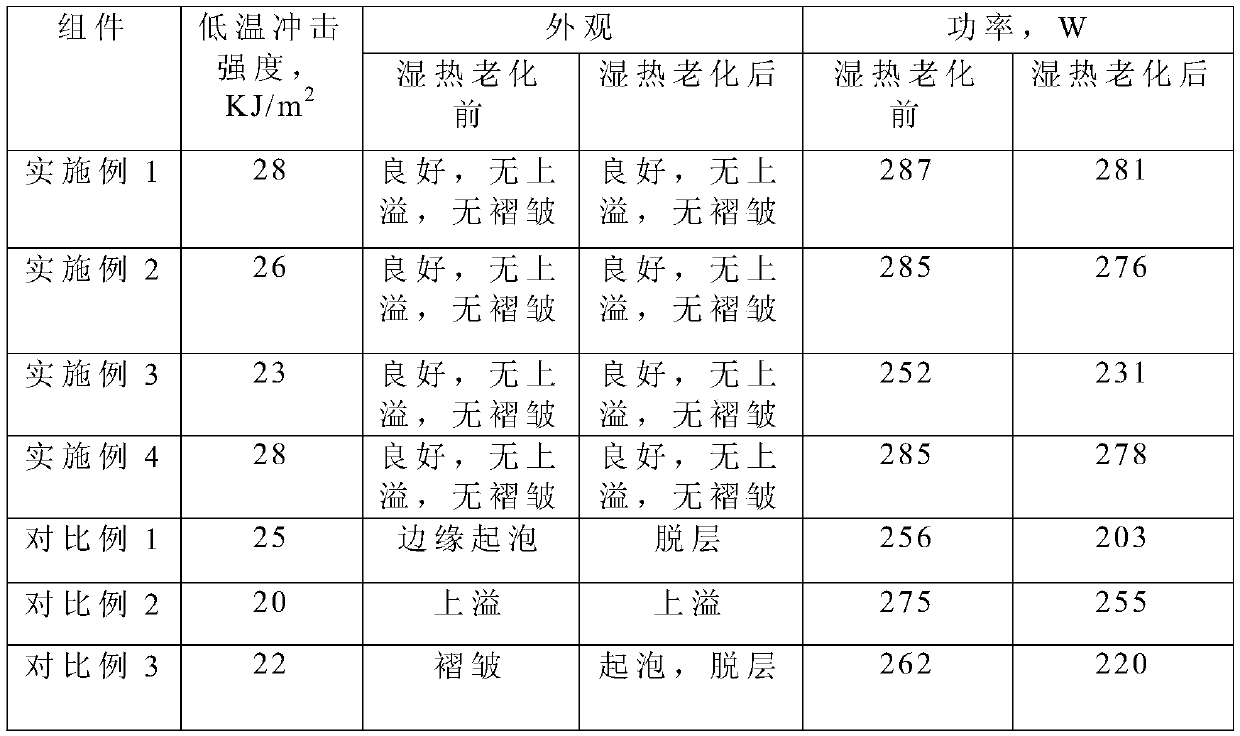

Examples

Embodiment 1

[0043] A kind of white encapsulation adhesive film that is used for solar cell module, its formula and preparation method are as follows:

[0044] (1) Add 2 parts of vinyltrimethoxysilane and 0.5 parts of dicumyl peroxide to 100 parts of POE resin (20% ethylene content, American Dow Company) and stir for 30 minutes at a speed of 600 rpm before putting in Melting extrusion granulation in a twin-screw extruder to obtain modified POE;

[0045] (2) Mix 60 parts of EVA resin (Va content 40%, American DuPont Company) and 40 parts of modified POE, and add 15 parts of titanium dioxide, 2 parts of γ-glycidyloxypropyl trimethoxysilane, 2 parts Tetrakis[β-(3',5'-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, 1 part of bis(2,2,6,6-tetramethyl-4-piperidinyl) Sebacate, 1 part of sodium stearate, 1 part of tert-butyl peroxybenzoate, 0.1 part of trimethylolpropyl trimethacrylate, continue to mix evenly, and then add it into a single-screw extruder for reaction extrusion Con...

Embodiment 2

[0048] Basically the same as implementation 1, the difference is: in the step (2), the material is changed to 20 parts of EVA resin and 80 parts of modified POE; the screw speed is 100rpm. The melt flow rate of the white packaging film S2 measured at 100°C and 5kg is 1.6g / 10min, and after being placed at room temperature for 7 days, the melt flow rate measured at 100°C and 5kg is 0.4g / 10min .

Embodiment 3

[0050] It is basically the same as Embodiment 1, except that in step (3), the adhesive film S3 is placed at room temperature for 5 days (the melt flow rate at this time is 0.5g / 10min) and then the solar module is assembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com