Winterization method for microbial oil

A microbial oil and winterization technology, which is applied in the direction of fat production, fat oil/fat refining, etc., can solve the problems of poor winterization effect and complicated winterization process, and achieve the effects of content reduction, refreshing taste, and improvement of physical and chemical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

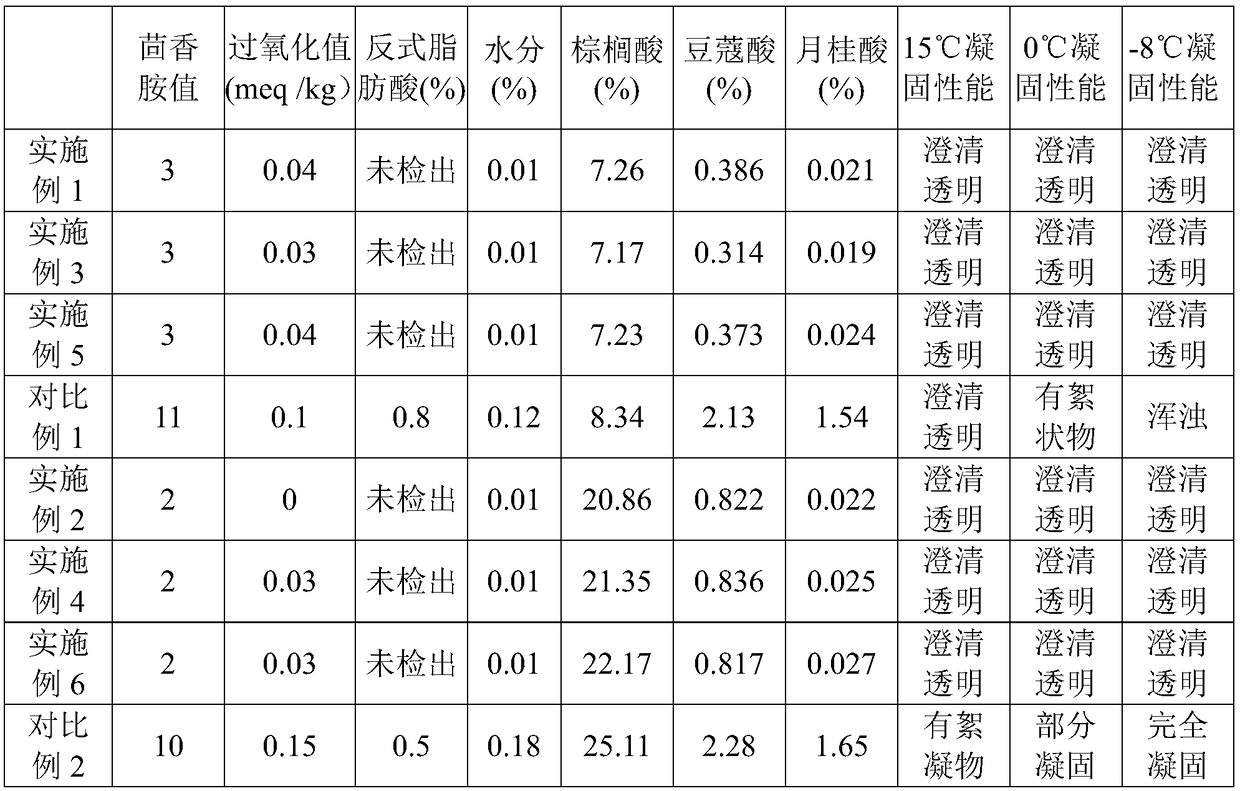

Examples

Embodiment 1

[0019] Use the refined oil of Mortierella alpina oil, and winterize it according to the following steps.

[0020] 1) Dehydration: Heat the grease after water washing, degumming and alkali refining to 85°C, and dehydrate under negative pressure of -0.1MPa for 35 minutes.

[0021] 2) Winterization at room temperature: the dehydrated oil will naturally cool down, and the oil temperature will drop to 20°C to maintain crystal growth. Winterization time at room temperature is 8 hours.

[0022] 3) Filtration: The oil after regular warming and winterization is filtered by a plate and frame filter press, the filter medium is industrial filter cloth, the filter pressure is 0.3MPa, and the ambient temperature is 18°C during the plate and frame filter press.

[0023] 4) Re-dehydration: heat the filtered oil to 85°C, and dehydrate under negative pressure of -0.1MPa for 30 minutes.

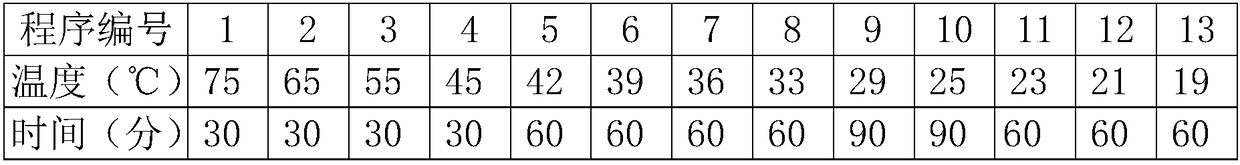

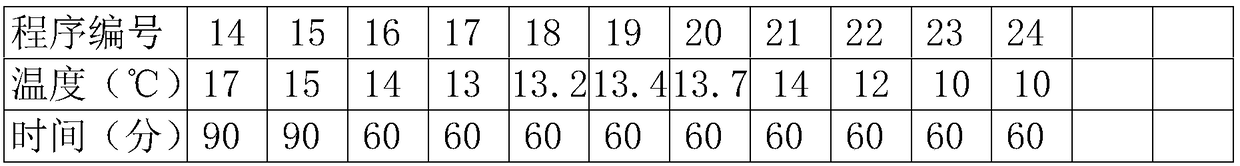

[0024] 5) Low temperature winterization: the dehydrated oil is cooled according to the set program, and ...

Embodiment 2

[0033] Using the refined oil of Schizochytrium oil, the steps and parameters of the winterization treatment are the same as those in Example 1.

Embodiment 3

[0035] Use the refined oil of Mortierella alpina oil, and winterize it according to the following steps.

[0036] 1) Dehydration: Heat the grease after water washing, degumming and alkali refining to 85°C, and dehydrate under negative pressure of -0.1MPa for 35 minutes.

[0037] 2) Winterization at room temperature: the dehydrated oil will naturally cool down, and the oil temperature will drop to 25°C to maintain crystal growth. The winterization time at room temperature is 24 hours.

[0038] 3) Filtration: Use a plate and frame filter press to filter the oil after regular warming and winterization. The filter medium is industrial filter cloth, the filter pressure is 0.2MPa, and the ambient temperature is 18°C during the plate and frame filter press.

[0039] 4) Re-dehydration: heat the filtered oil to 85°C, and dehydrate under negative pressure of -0.1MPa for 30 minutes.

[0040] 5) Low temperature winterization: the dehydrated oil is cooled according to the set program, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com