Preparation of SiO2/organic polymer composite proton exchange membrane

A technology of polymer and proton membrane, which is applied to fuel cell components, fuel cells, cells, etc., can solve the problems of increased production cost of composite membranes, complex operation of the synthesis process, and reduced conductivity, and achieve increased quantity and methanol penetration The effect of low rate and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one, one of the preparation of SiOx (OH) y (OR) z alcohol sol

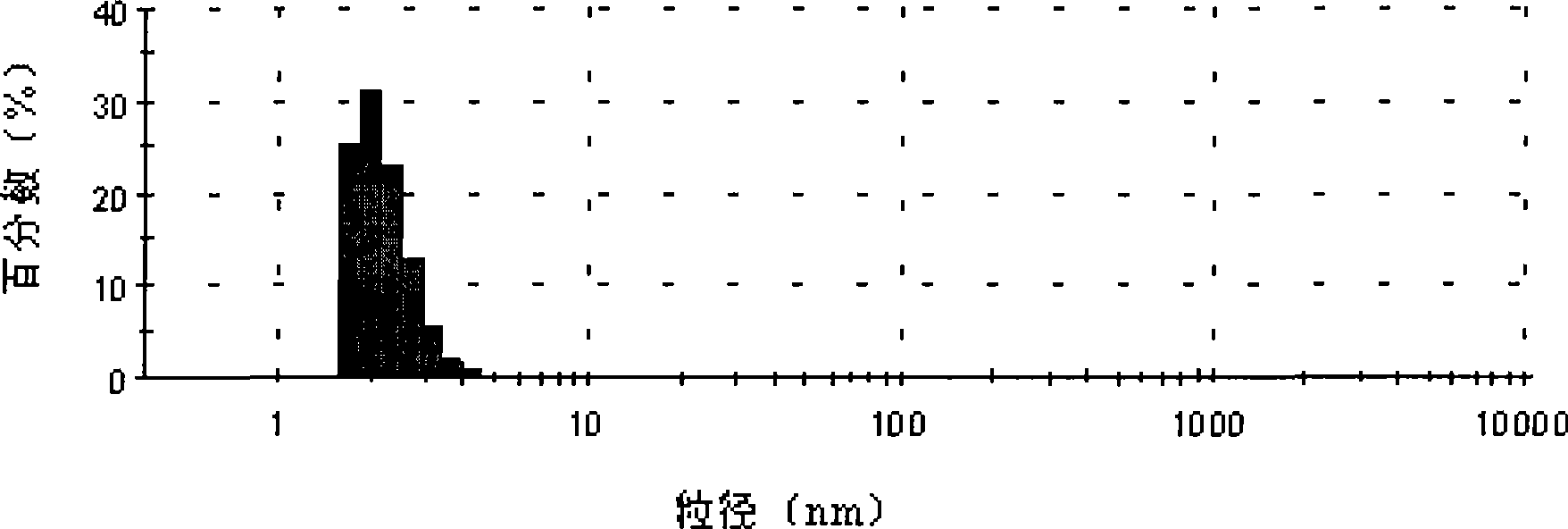

[0032] Mix 150 ml tetraethyl orthosilicate (TEOS), 50 ml ethanol and 18.2 ml 0.5M HCl aqueous solution, stir and react for about 1 hour to obtain colorless and transparent SiOxH 2 O·y(OR)z (incompletely hydrolyzed and condensed organic silicate) alcohol sol. The Zetasizer Nano—ZS type laser particle size analyzer of Malvern Instruments Co., Ltd. was used to measure and analyze the particle size of the synthesized sol, and the particle size of the synthesized sol was shown in figure 1 .

Embodiment 2

[0033] Embodiment two, the preparation two of SiOx (OH) y (OR) z alcohol sol

[0034] Mix 150 mL of tetraethyl orthosilicate (TEOS), 100 mL of methanol, and 12.1 mL of 1.0M HNO 3 The aqueous solution was mixed, stirred and reacted for about 1 hour, and a colorless and transparent SiOx·(OH)y(OR)z alcohol sol was obtained. The Zetasizer Nano—ZS laser particle size analyzer of Malvern Instruments Co., Ltd. was used to measure and analyze the particle size of the synthesized sol, which was also between 1 and 5 nanometers.

Embodiment 3

[0035] Embodiment three, the preparation three of SiOx (OH)y(OR)z alcohol sol

[0036] Mix 150 mL of orthomethylsilicate (TMOS), 100 mL of ethanol, and 12.1 mL of 1.0M HNO 3 The aqueous solution was mixed, stirred and reacted for about 1 hour, and a colorless and transparent SiOx·(OH)y(OR)z alcohol sol was obtained. The Zetasizer Nano—ZS laser particle size analyzer of Malvern Instruments Co., Ltd. was used to measure and analyze the particle size of the synthesized sol, which was also between 1 and 5 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com