A method of using differential pressure polymerization temporary plugging agent to realize temporary plugging diversion to fracturing

A technology of temporary plugging agent and differential pressure, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc. Due to the large scale and difficulty in opening low-level intervals, the effect of increasing the complexity of cracks, improving the complexity of cracks and lowering the construction cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of SM temporary plugging agent is:

[0063] (1) SM-L: 60%-80% polylactic acid (molecular weight 35,000-50,000) + 10%-20% sodium carboxymethylcellulose (industrial grade, commercially available) + 10%-20% polyacrylamide (molecular weight ≥ 12 million, commercially available) + 0-10% clear water; preparation method: compound under the conditions of pressure range 5-20MPa and temperature range 60-120°C for 2-5h, crush after consolidation, and sieve to obtain 170-400 mesh powder is the finished product.

[0064] (2) SM-H: 60%-80% polylactic acid (molecular weight 60,000-90,000) + 10%-20% sodium carboxymethyl cellulose (industrial grade, commercially available) + 10%-20% polyacrylamide (molecular weight ≥ 12 million, commercially available) + 0-10% clear water; preparation method: compound under the conditions of pressure range 5-20MPa and temperature range 60-120°C for 2-5h, crush after consolidation, and sieve to obtain 170-400 mesh powder is the f...

Embodiment 1

[0067] A method for realizing temporary plugging diversion to fracturing by using differential pressure polymerization temporary plugging agent, comprising the following steps:

[0068] 1) Preparations before construction: The formation pressure coefficient of gas well A is 1.9-2.0, and the reservoir temperature is about 90°C. According to the reservoir pressure and temperature, select the SM type powder temporary plugging agent and the 6M type particle temporary plugging agent with an applicable temperature of 90-160°C. The plugging agent is used to temporarily plug perforation holes between horizontal well intervals.

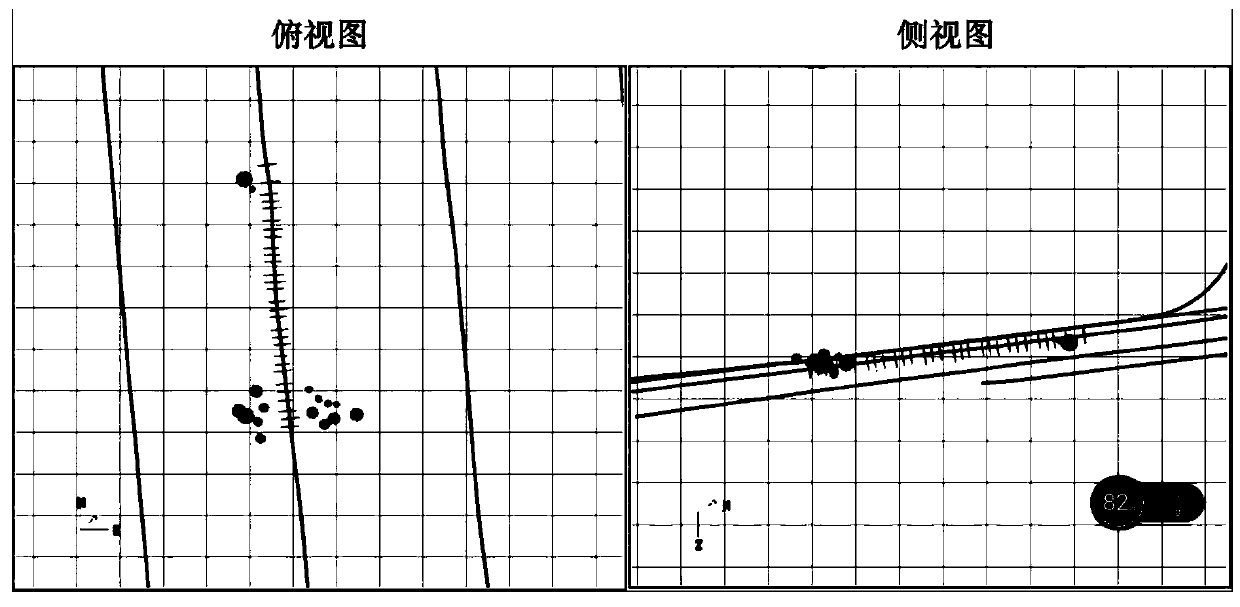

[0069] 2) Determine the dosage of temporary plugging agent: the horizontal section of gas well A that needs to be temporarily plugged and diverted to fracturing is about 639m long, with a perforation density of 16 holes / m, 29 perforation clusters in this section, and a total of 464 perforations. According to the number of channels, the dosage of temporary plug...

Embodiment 2

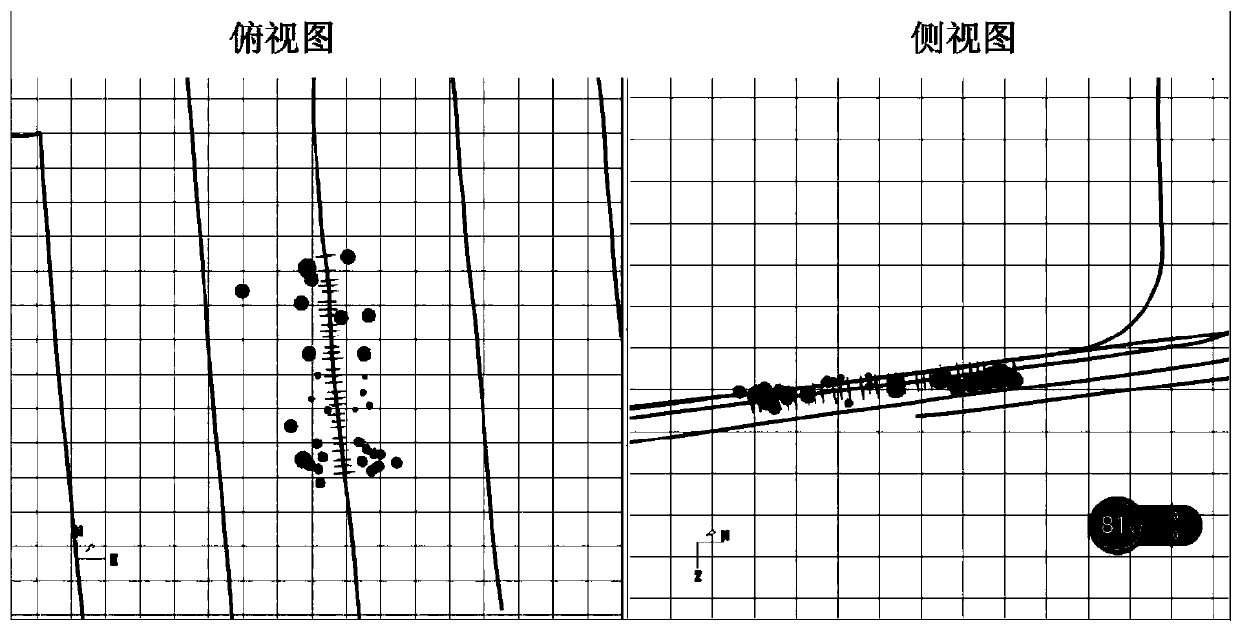

[0080] A method for realizing temporary plugging diversion to fracturing by using differential pressure polymerization temporary plugging agent, comprising the following steps:

[0081] 1) Preparation before construction: The formation pressure coefficient of gas well B is 1.4, and the reservoir temperature is about 95°C. According to the reservoir pressure and temperature, select the powder type temporary plugging agent and granular type temporary plugging agent with an applicable temperature of 90-160°C. Construction is carried out in the construction method of temporarily plugging perforation holes between horizontal well sections.

[0082] 2) Determine the dosage of temporary plugging agent: The horizontal section that needs to be temporarily plugged and diverted to fracturing in gas well B is 14 sections, 5-14 and 16-19. The perforation density is 16 holes / m, and the total number of perforation holes is 672. According to the number of channels, the dosage of temporary plu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com