Data interaction system and design method for propellant replenishment based on fdir technology

A data interaction and system design technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve the problems of occupying measurement and control resources, transmission delay of air-ground communication links, and fault spread, and reduce The effect of measurement and control network configuration, reducing dependencies and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

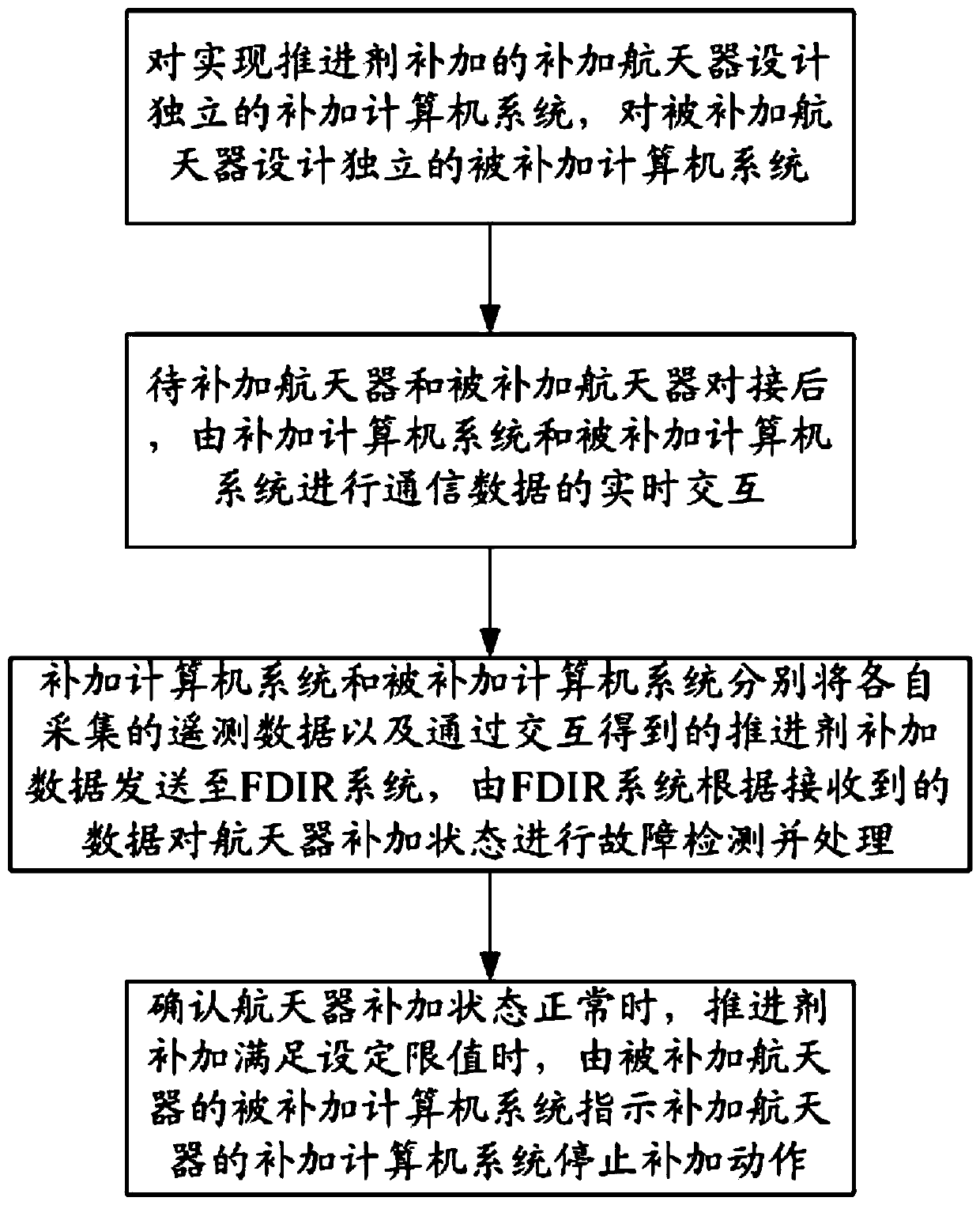

Method used

Image

Examples

Embodiment approach

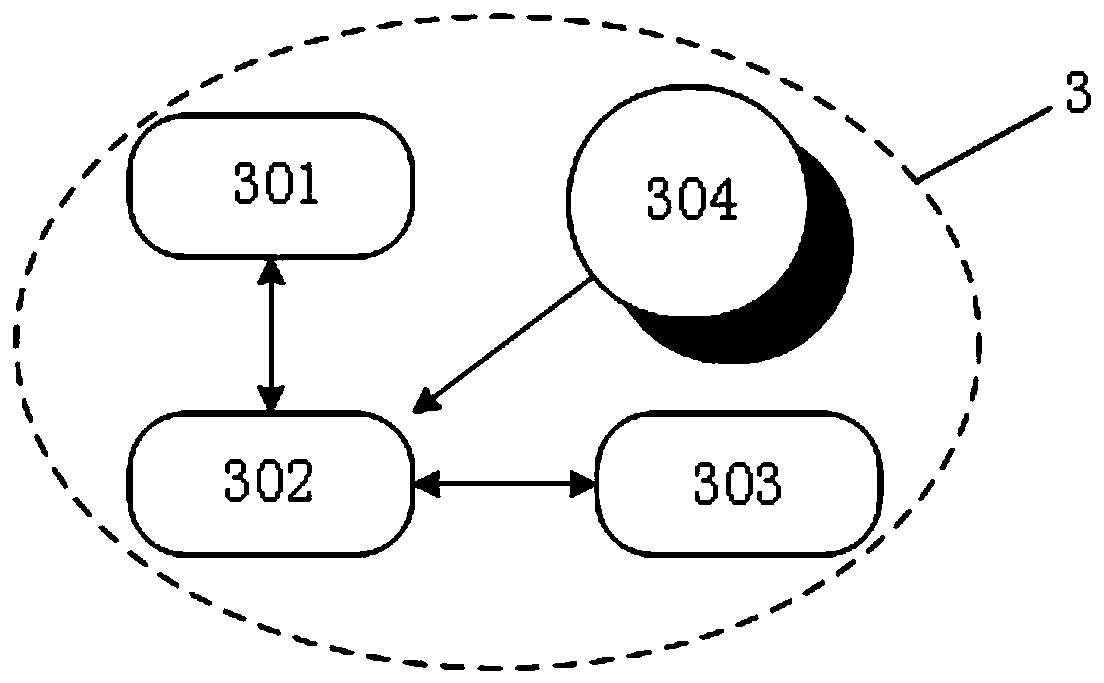

[0068] According to one embodiment of the present invention, the FDIR system includes:

[0069] The fault detection module is used for fault detection in the supplementary process, and sends fault information to the fault isolation module;

[0070] The fault isolation module analyzes the additional fault information, locates the source of the fault, and determines the type of fault;

[0071] The fault recovery module adopts reconstruction and mode switching methods to replace the fault supplementary pipeline or equipment with redundant backup pipeline or equipment;

[0072] A fault database is added to store fault information, corresponding fault types, and recovery strategies for corresponding faults.

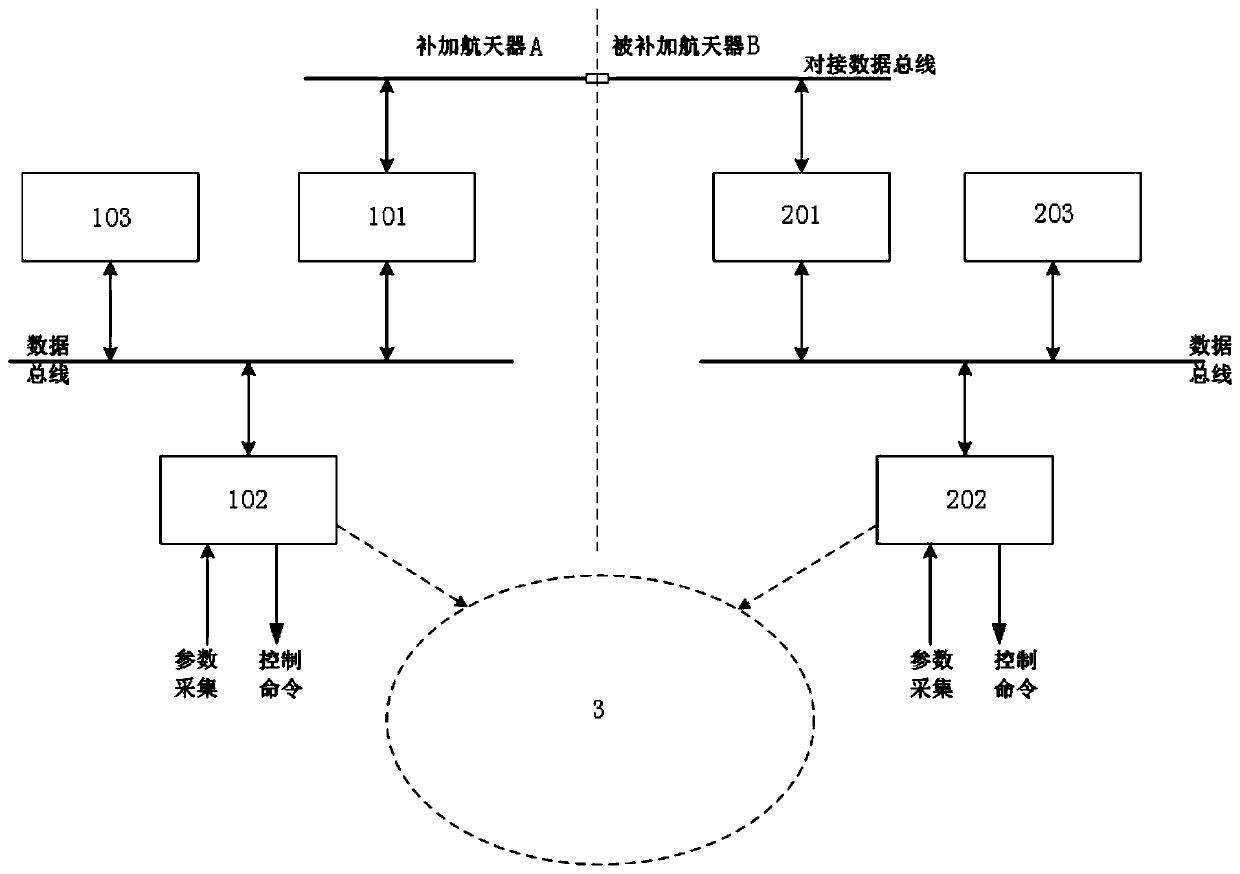

[0073] figure 2 Schematic representation of the structural layout of the propellant replenishment data interaction system based on FDIR technology according to the present invention. Such as figure 2 As shown, the propellant supplementary data interaction system based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com