A method for optimizing the dynamic performance of a six-axis industrial robot based on a finite element

An industrial robot and optimization method technology, applied in design optimization/simulation, instrumentation, special data processing applications, etc., can solve problems such as low robot positioning accuracy, resonance, and low-order modal frequency of the whole machine, so as to avoid blindness , Reduce the risk of resonance, improve the effect of low-order modal frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Embodiment 1: The method for optimizing the dynamic performance of a six-axis industrial robot based on finite elements includes the following steps:

[0029] In order to facilitate the subsequent comparison and evaluation of the optimization performance of the industrial robot body, the rigid dynamic model and the rigid-flexible coupling dynamic model of the six-axis industrial robot were respectively established.

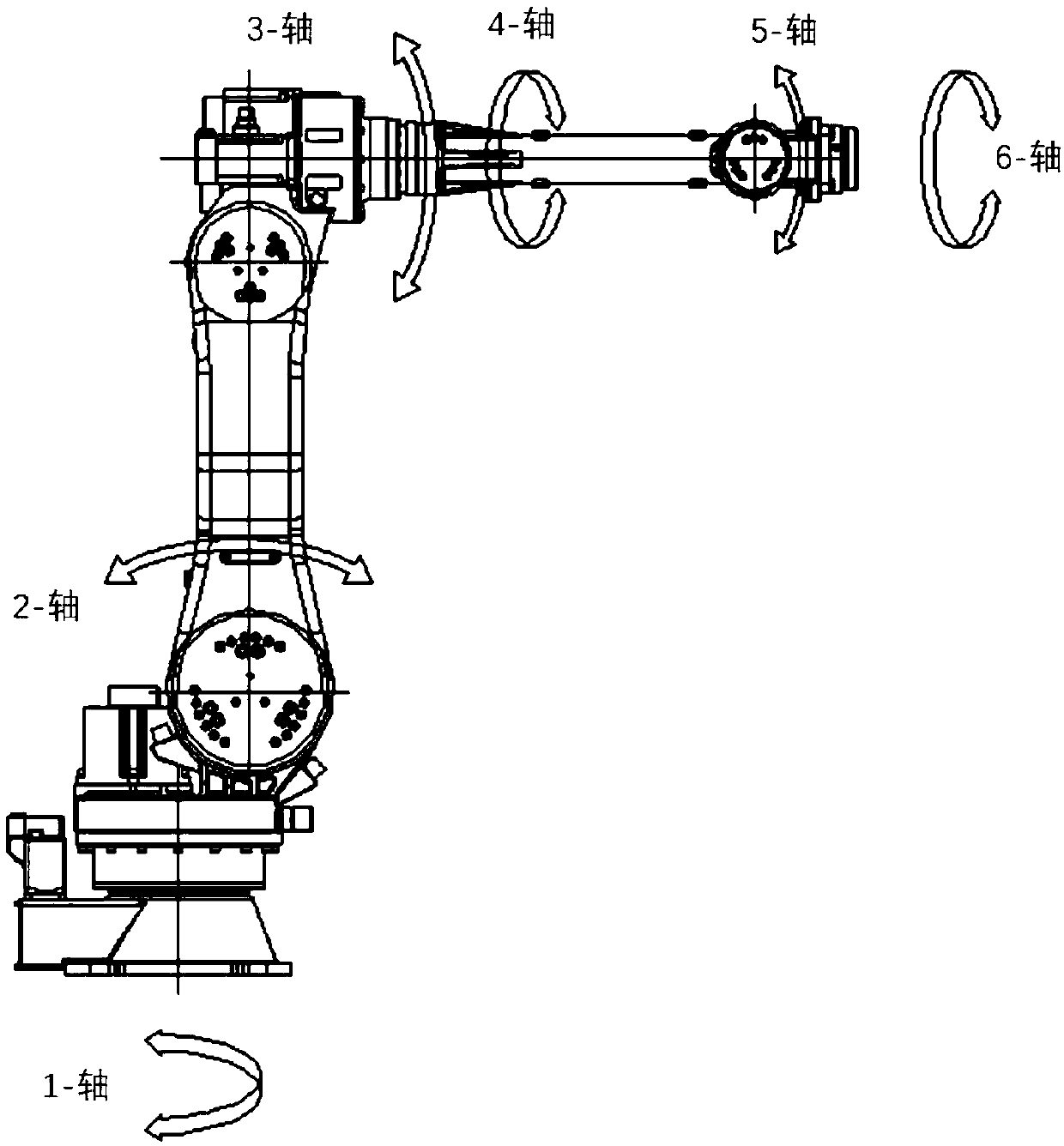

[0030] Step 1: Perform modal analysis on each part of the six-axis industrial robot to determine the low-order modal frequency and stiffness distribution of each part; the parts of the six-axis industrial robot include forearm, wrist, arm, base, Elbow seat and waist seat; the dynamic performance is the amplitude of the manipulator during high-speed operation;

[0031] Step 2: According to the stiffness distribution of each part determined in step 1, optimize the part with the smallest stiffness of each part;

[0032] Combined with the design experience of ...

specific Embodiment approach 2

[0058] Embodiment 2: This embodiment differs from Embodiment 1 in that: In the first step, modal analysis of each part of the six-axis industrial robot is performed using ANSYS software.

[0059] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0060] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: after step two in step three optimizes each part, the specific process of establishing the finite element model of the six-axis industrial robot machine is as follows:

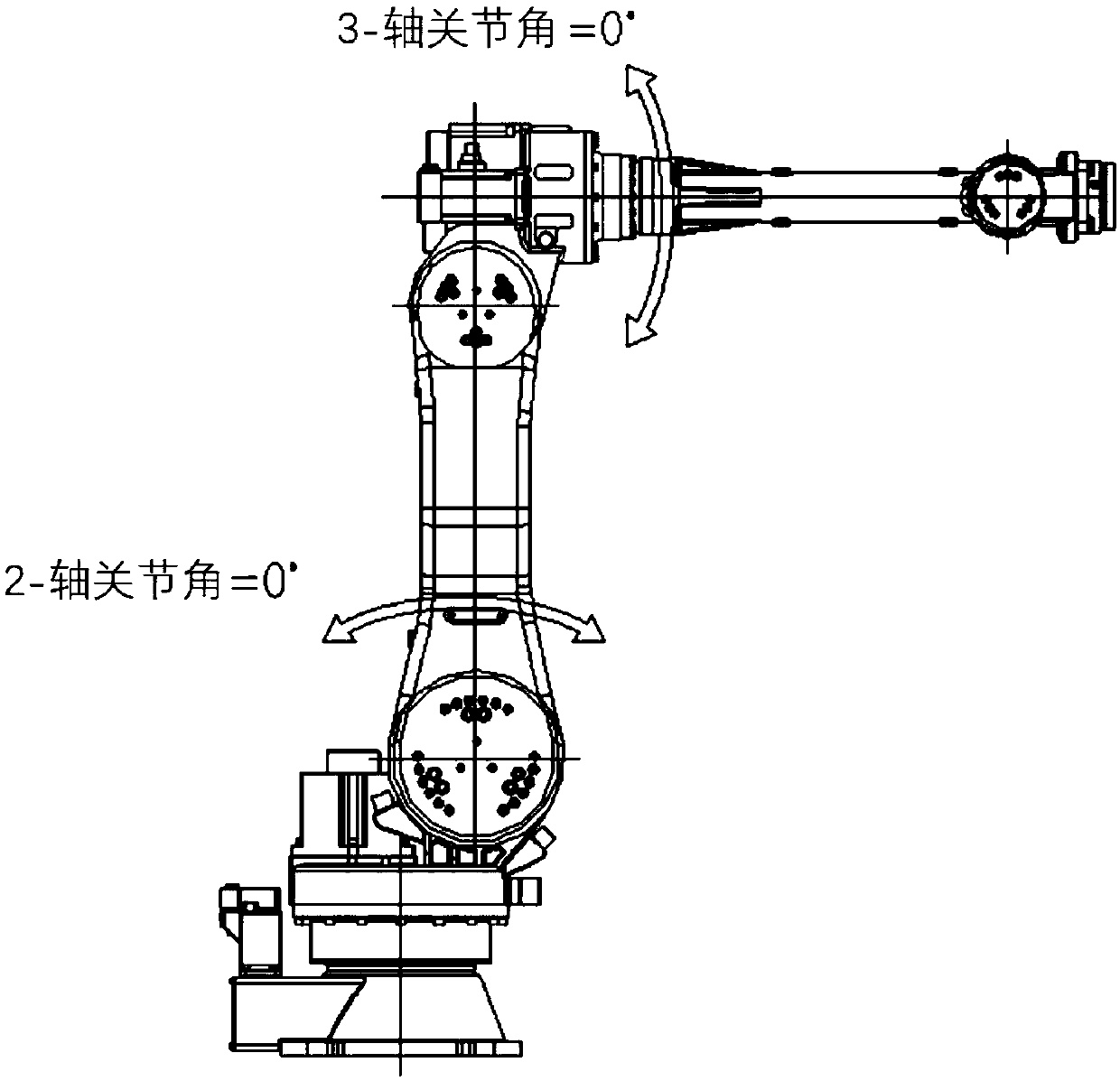

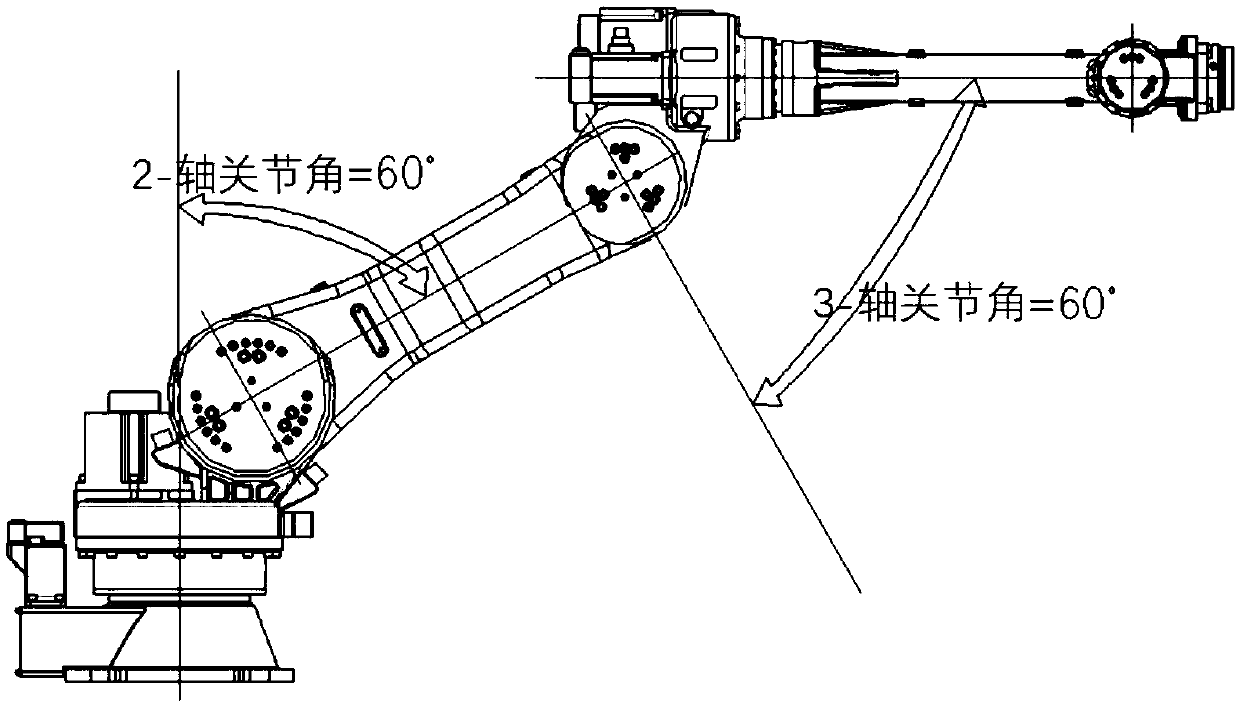

[0061] In SolidWorks, assemble the parts of the six-axis industrial robot according to the different configurations of joint 2 (big arm swing joint) and joint 3 (small arm swing joint), and generate the x_t intermediate file; The connection constraints of the parts of the six-axis industrial robot are equivalent to mass blocks; the parts of each six-axis industrial robot are meshed to generate the finite element model of the whole machine;

[0062] The rigid body includes a motor, a reducer and a driver.

[0063] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com