Winding device for greenhouse heat preservation quilt

A greenhouse and winding device technology, which is applied in drinking water devices, water supply devices, greenhouse cultivation, etc., can solve the problems of winding and insulation film not easy to replace, so as to save the use of electric energy, improve the efficiency of photovoltaic power generation, and improve the economy. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

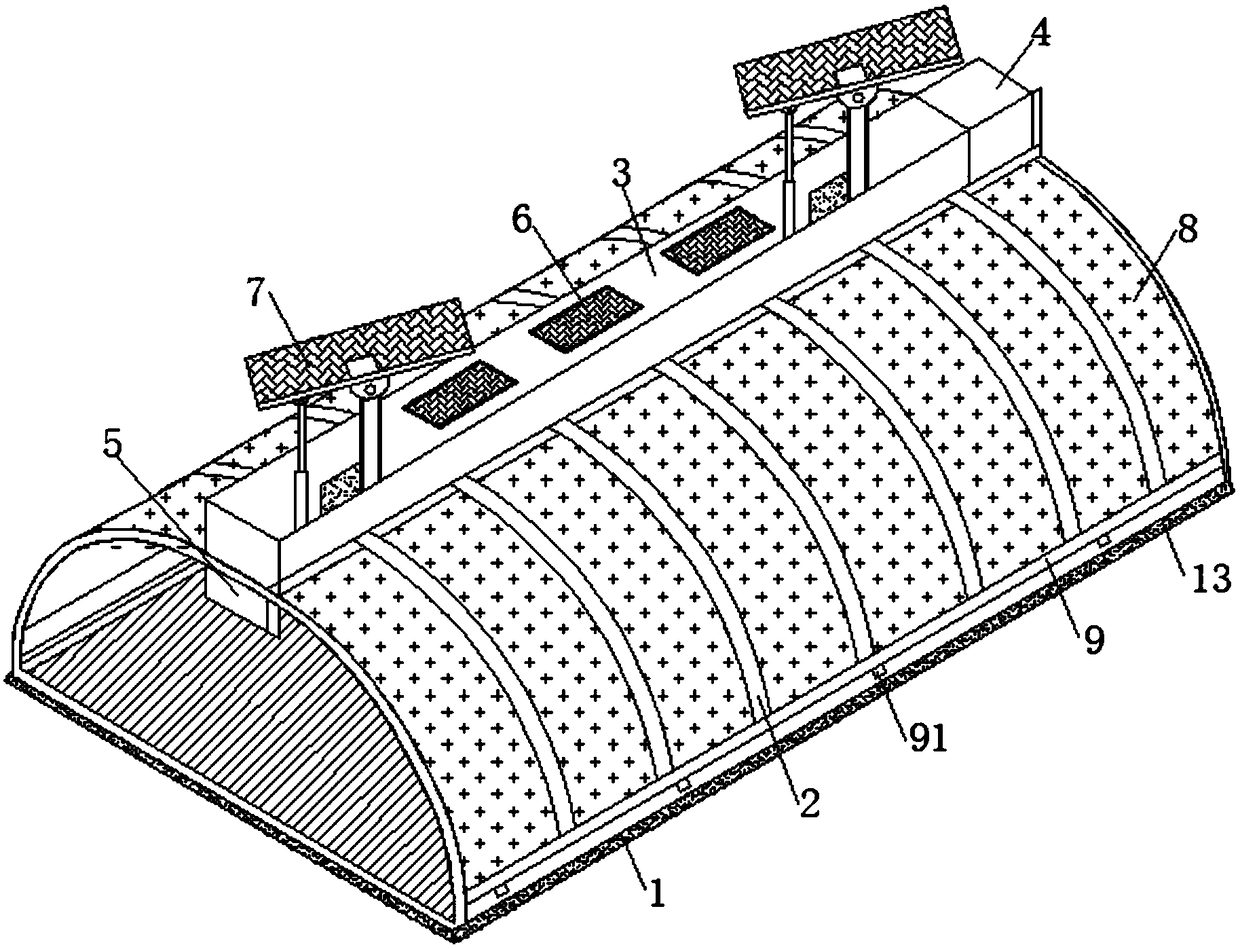

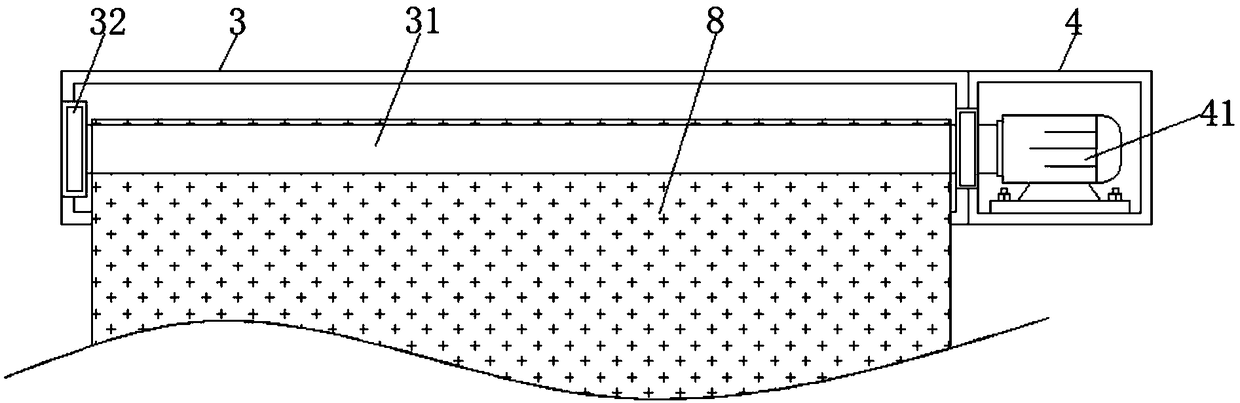

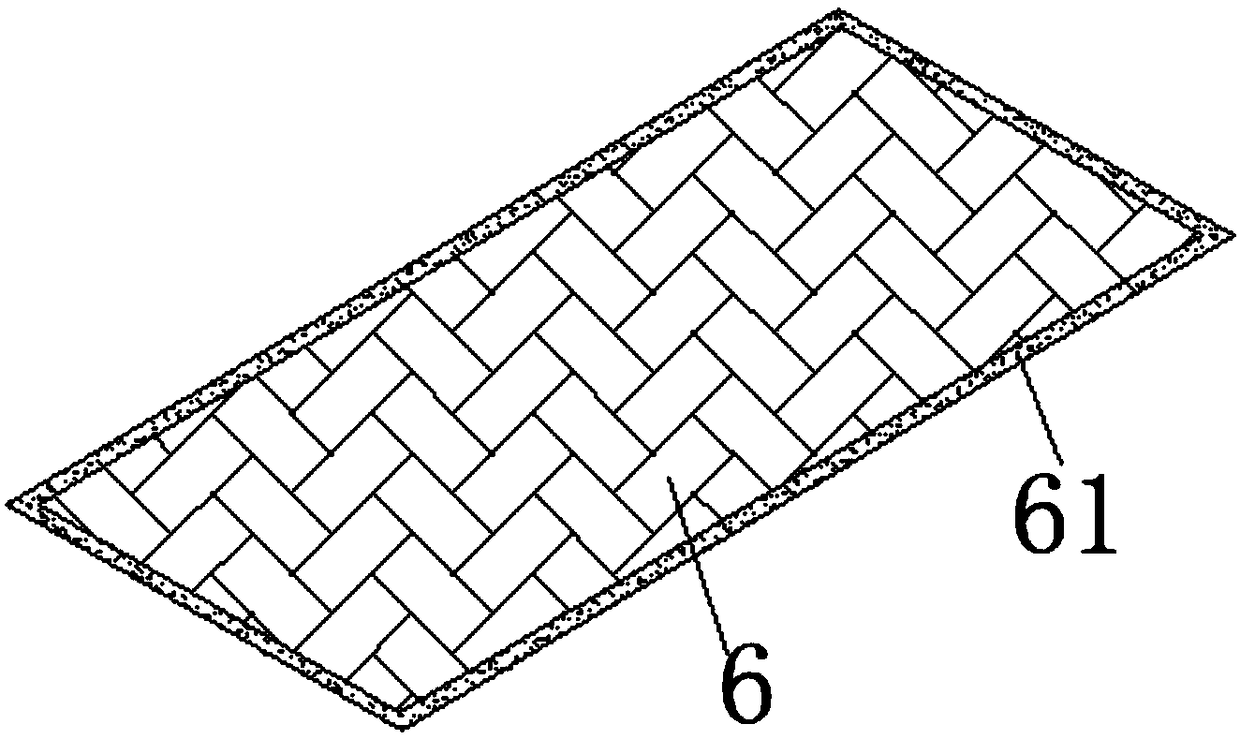

[0030] as attached figure 1 to attach Image 6 As shown, a winding device for greenhouse heat preservation quilts includes a greenhouse body, a drive motor 41, a heat preservation quilt 8, a connecting rod 9, a power generation device 7, and an electric push rod 73. The greenhouse body includes an arc-shaped fixing frame 2, a winding Box 3, drive box 4, controller 5 and connection socket 10, the model of controller 5 is STM32F103, controller 5 adopts 40-pin dual in-line DIP, has 128 RAM units and 4K ROM, and has Two 16-bit timing counters, two external interrupts, two timing counting interrupts, a serial interrupt and four 8-bit parallel input ports, the drive motor 41 is located in the drive box 4, and the output shaft of the drive motor 41 is connected to the The winding shaft 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com