A vertical take-off and landing fixed-wing aircraft

A vertical lift, fixed-wing technology, applied in the field of aircraft, can solve the problems of increased resistance, large take-off and landing space, small lift, etc., to achieve the effects of improving stability, reducing resistance, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

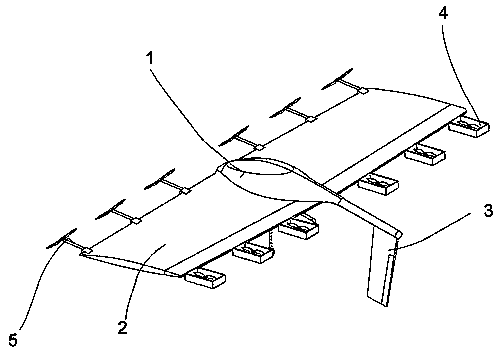

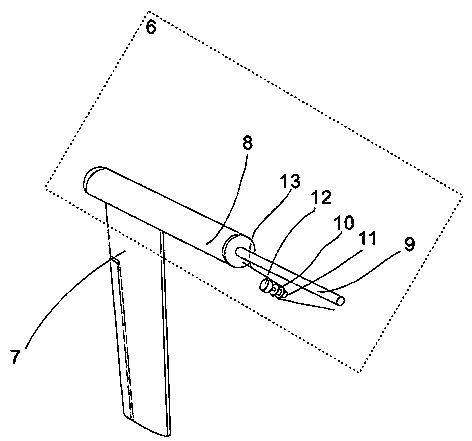

[0040] Embodiment 1 of the present invention discloses a fixed-wing aircraft that can be lifted vertically, including a fuselage 1, wings 2, a retractable empennage 3, a rear rotor mechanism 4 and a front rotor mechanism 5; the wings 2 are symmetrically arranged on the fuselage 1 on both sides; the telescopic empennage 3 is arranged on the tail of the fuselage 1; the rear rotor mechanism 4 is arranged on the rear side of the wing 2, and the rear rotor mechanism 4 includes a retractable telescopic mechanism 15; the front rotor mechanism 5 advances along the The direction is set on the front side of the wing 2, and the front rotor mechanism 5 can be tilted upwards by 0-90°.

[0041] The beneficial effects of the above preferred technical solutions are: a vertical liftable fixed-wing aircraft disclosed by the present invention, wherein the telescopic empennage 3 can be stretched back and forth according to the requirements of use, and the empennage 7 and the aircraft can be increa...

Embodiment 2

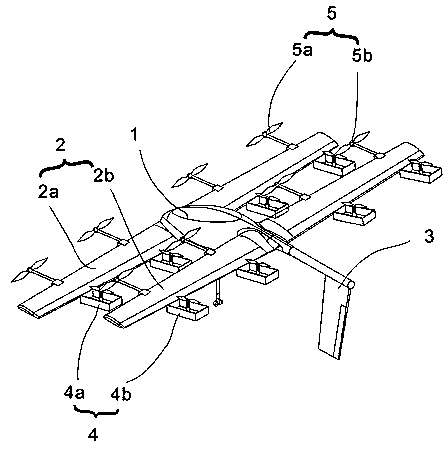

[0059] A fixed-wing aircraft capable of vertical lift, comprising a fuselage 1, wings 2, a retractable empennage 3, a rear rotor mechanism 4 and a front rotor mechanism 5;

[0060] The wing 2 comprises a first group of wings 2a and a second group of wings 2b, the first group of wings 2a and the second group of wings 2b are located on different horizontal planes, and are located on different vertical planes, the first group of wings 2a and the second group of wings 2b The second group of wings 2b are all symmetrically arranged on both sides of the fuselage, the front sides of the first group of wings 2a and the second group of wings 2b are all provided with a front rotor mechanism 4, the first group of wings 2a and the second group of wings The rear side of the wing 2b is provided with a rear rotor mechanism 5;

[0061] The retractable empennage 3 is arranged on the afterbody of the fuselage 1; the rear rotor mechanism 4 is arranged on the rear side of the wing 2, and the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com