Rail joining method, suspension system, computer equipment and storage medium

A hanging and equipment technology, which is applied in the field of hanging systems, can solve problems such as the deviation of the timing of the rail separation mechanism and the rail joining mechanism, and the deviation of the timing of the rail joining mechanism, so as to improve the accuracy of rail joining and track change. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

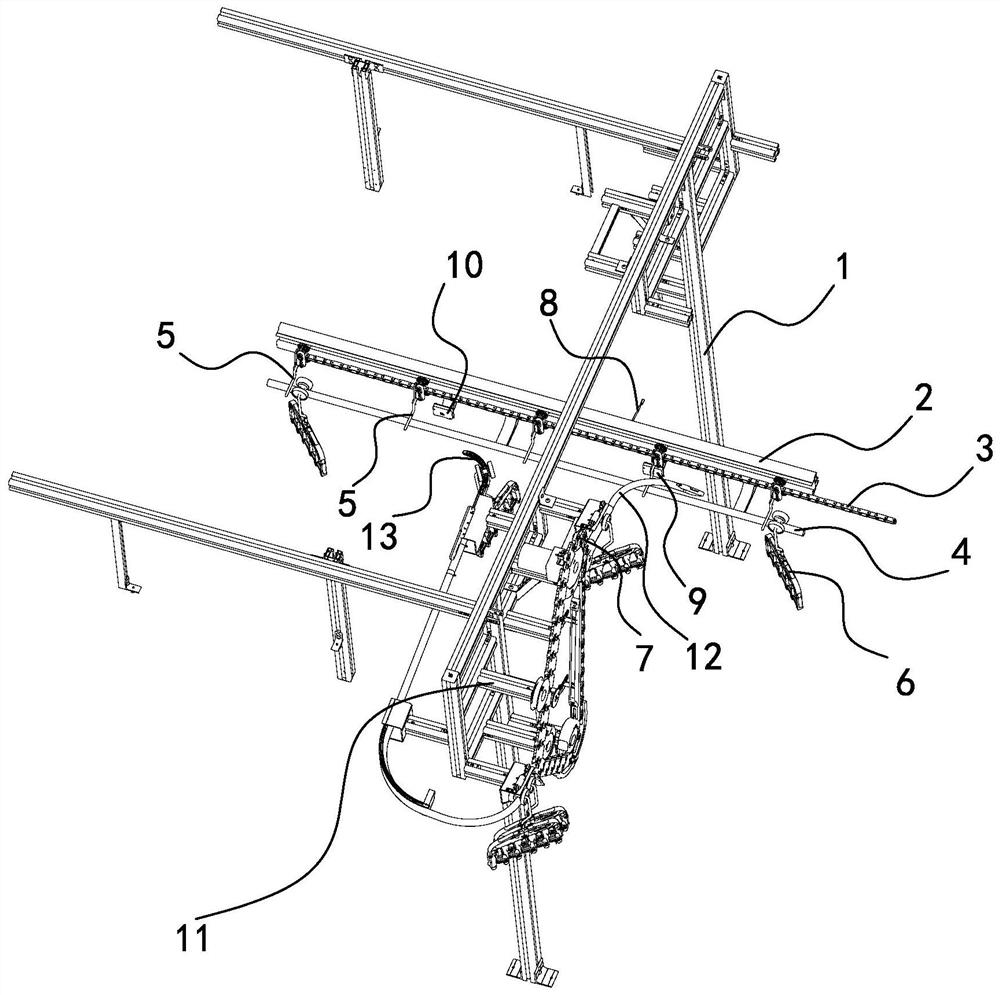

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

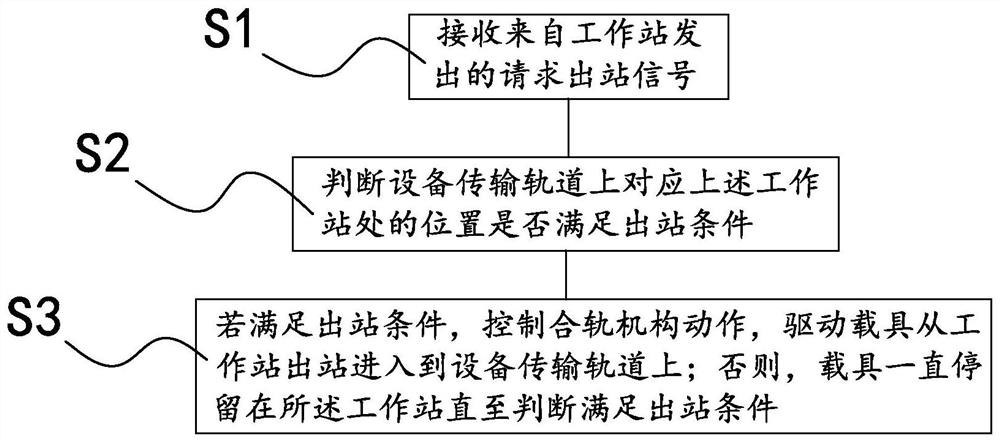

[0031] Such as figure 1 As shown, this rail alignment method includes steps:

[0032] S1. Receive an outbound request signal from the workstation;

[0033] S2. Judging whether the position corresponding to the above-mentioned workstation on the equipment transmission track meets the rail-fitting condition;

[0034] S3. If the rail alignment condition is satisfied, control the rail alignment mechanism to drive the carrier out of the workstation and onto the equipment transmission track; otherwise, the carrier stays at the workstation until it is judged that the rail alignment condition is satisfied.

[0035] Specifically, the exit request signal in step S1 is sent when the sensor installed at the exit of the workstation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com