Conveyor belt box stacking device and stacking method

A technology of conveyor belts and boxes, used in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The case sorting and conveying device of the present invention is a device of the case palletizing system, the line transfer mechanism is an integral part of the case sorting and conveying device, and the case sorting and conveying device is used in the case palletizing system.

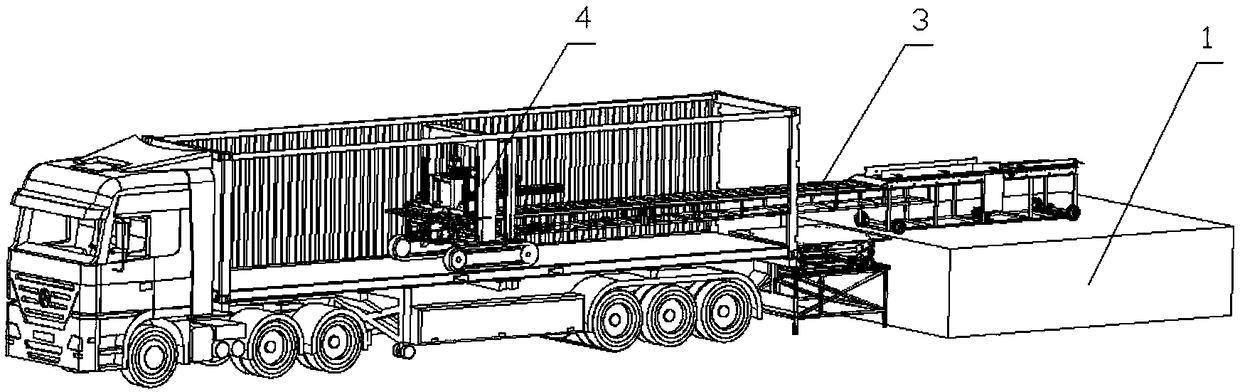

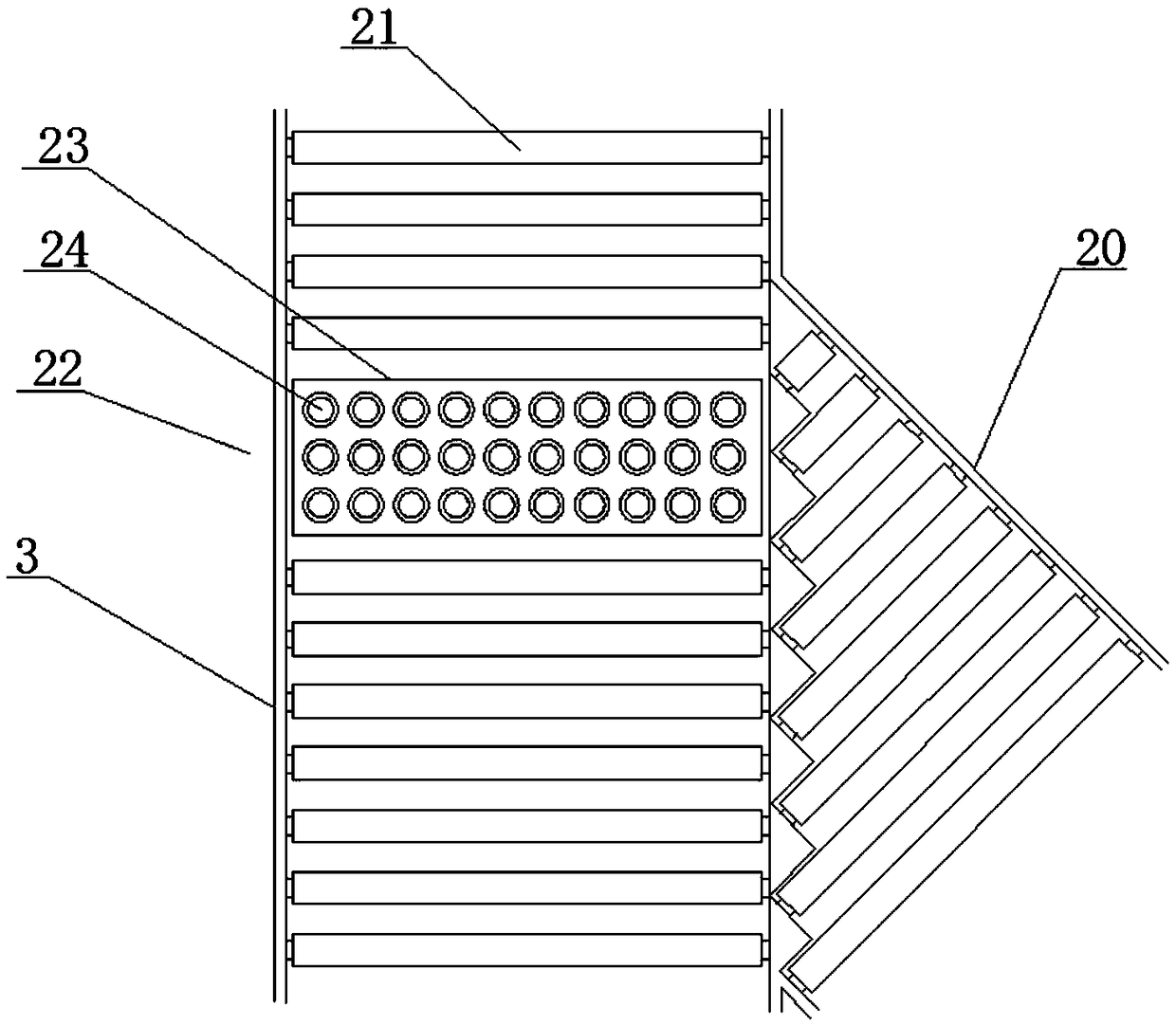

[0053] Such as figure 1 As shown, the box body automatic loading system includes a control system, a loading platform 1, a conveyor belt 3 and a stacking device 4 connected to the conveyor belt 3. A box merging device is arranged on the conveyor belt 3 .

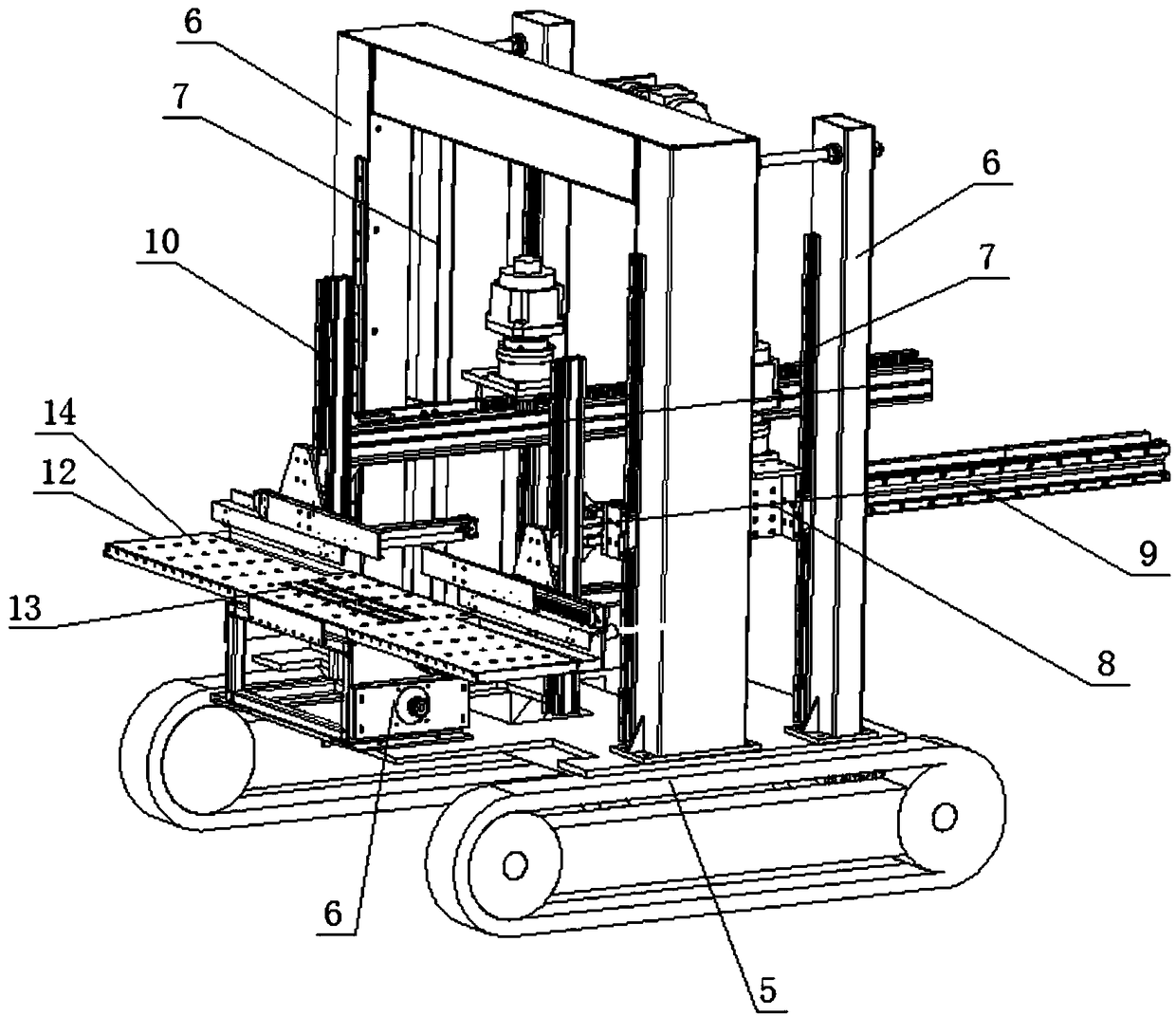

[0054] A sorting device is arranged on the conveyor belt, and the sorting device can separate the horizontally placed and vertically placed boxes and turn them over, so that the horizontally placed and vertically placed boxes are placed uniformly; the sorting device on the conveyor belt After that, a box merging device is set to merge two adjacent boxes on the conveyor belt; a box stacking device is set after the merging device on the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com