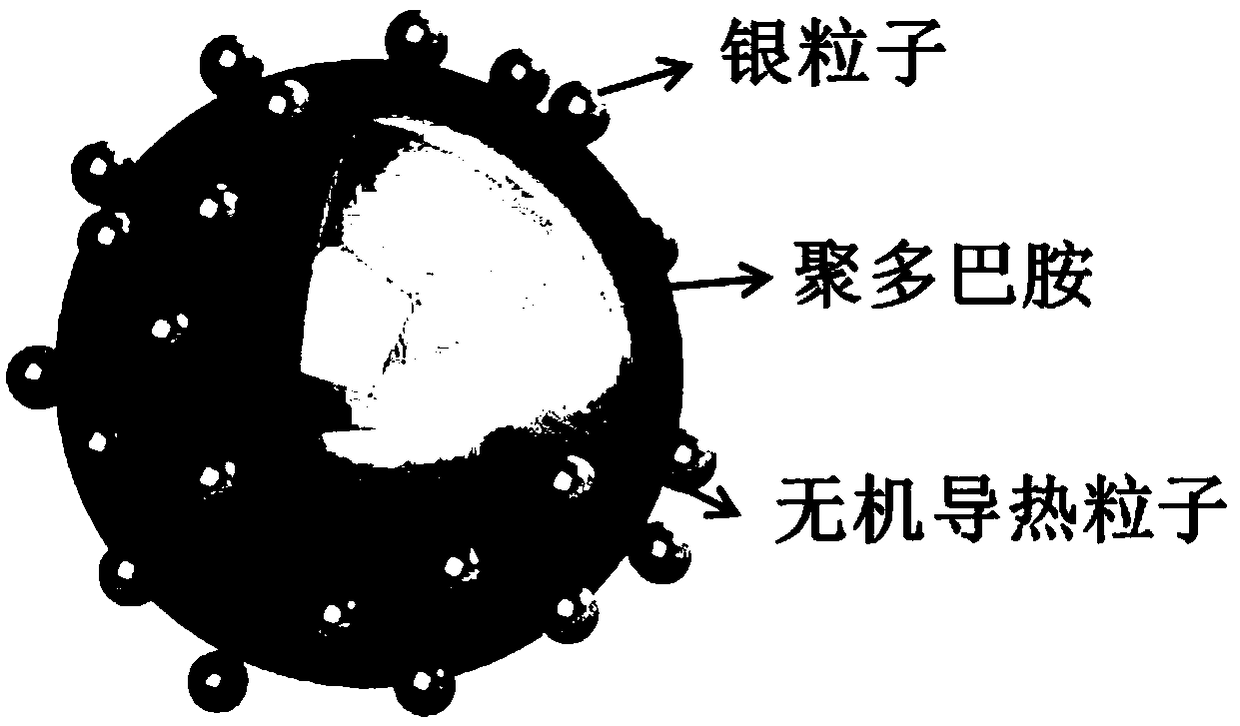

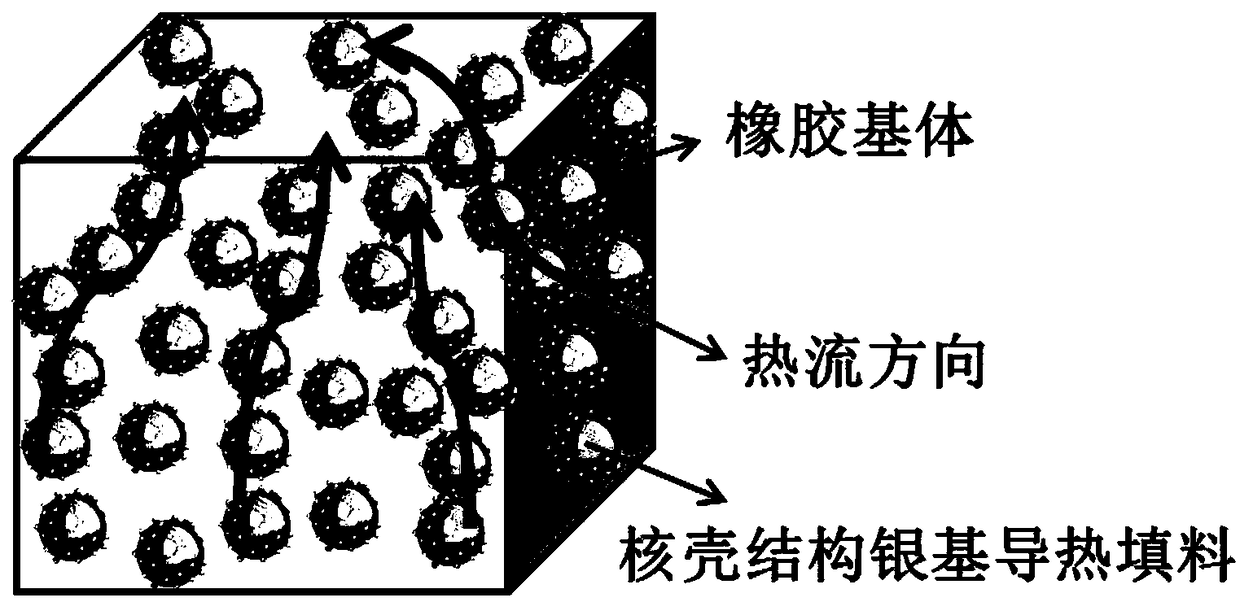

Core-shell-structured silver-based heat-conductive rubber composite material and preparation method thereof

A technology of core-shell structure and heat-conducting rubber, applied in the field of polymers, can solve the problems of complex reaction steps, uneconomical and environmental protection, and affecting performance, and achieve the effects of reducing the amount of silver used, good dispersion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

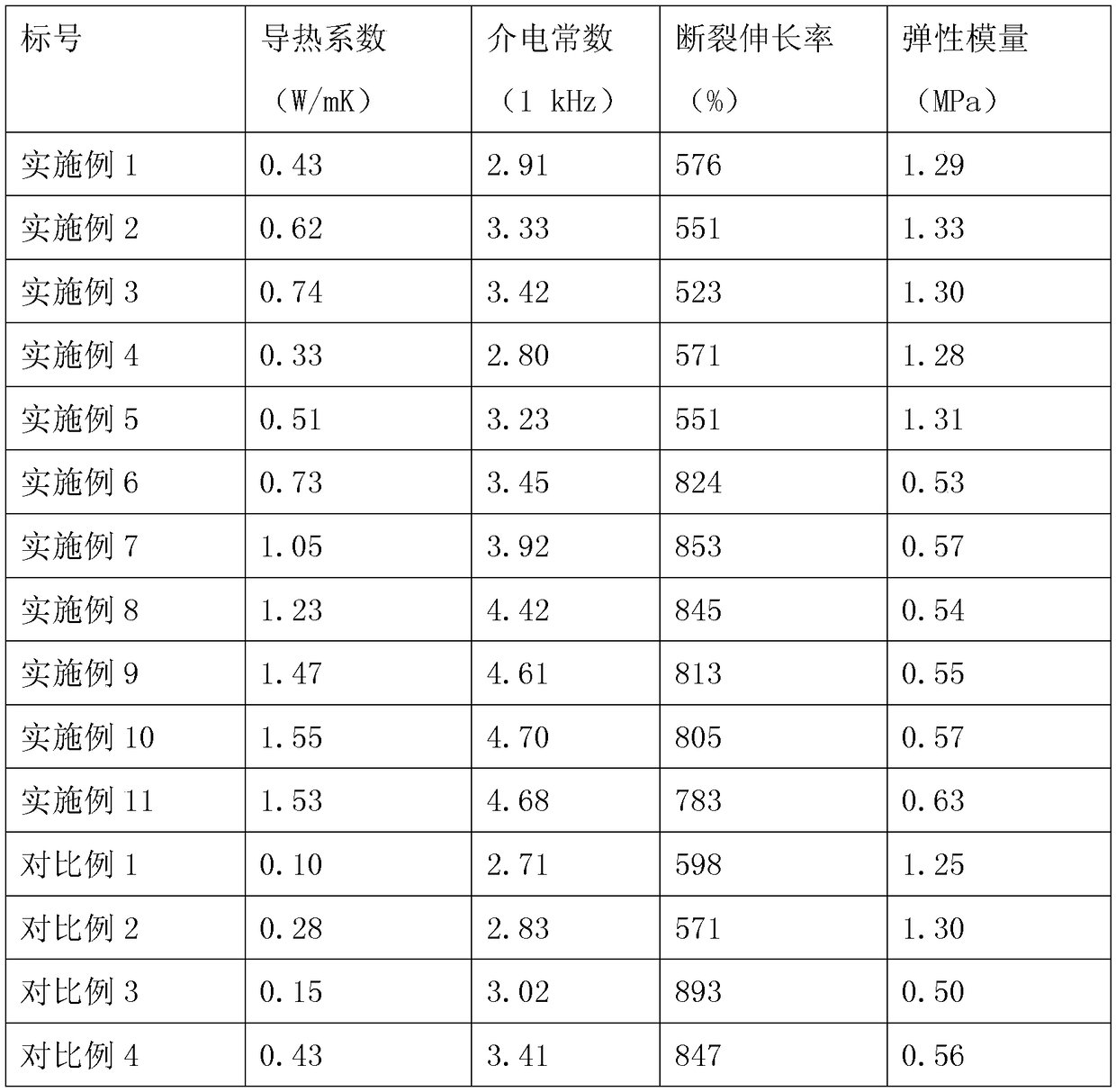

Embodiment 1

[0028] (1) Take 100ml of configured dopamine aqueous solution with a mass fraction of 2g / L, and adjust the aqueous solution to pH 8.5 with Tris (Tris), then add 6g of boron nitride particles with a particle size of 1 μm, Under room temperature, the reaction was stirred at a stirring rate of 60 rpm for 18 hours. After the reaction, suction filtration, deionized water washing, and vacuum drying were performed to obtain polydopamine-coated boron nitride heat-conducting particles.

[0029] (2) Configure a silver nitrate solution with a concentration of 10 g / L, titrate with ammonia water until the precipitate just disappears, and obtain a silver plating solution.

[0030] (3) Soak the polydopamine-coated boron nitride heat-conducting particles in step (1) in the 200ml silver plating solution obtained in step (2) under stirring conditions, and add an equal volume concentration of 20g / L glucose solution, Stir mechanically for 1 h at room temperature, vacuum filter, wash with deionize...

Embodiment 2

[0036] The preparation method is the same as in Example 1, except that the amount of core-shell structure silver-based thermally conductive boron nitride is 100 parts by mass. The test results are shown in Table 1.

Embodiment 3

[0038] The preparation method is the same as in Example 1, except that the particle size of boron nitride is 3 μm. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com