Manufacturing technology of wear-resistant waterproof cloth

A production process and technology for waterproof coatings, which are applied in the processing of textile materials, the configuration of equipment for processing textile materials, and the processing of liquid/gas/steam textile materials to achieve strong wear resistance, reduce rotation time, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

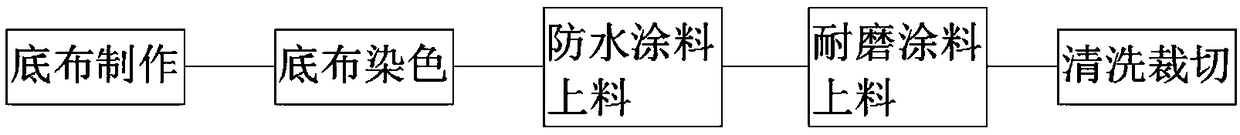

[0025] like figure 1 As shown, this specific embodiment adopts the following technical scheme: a kind of wear-resistant waterproof cloth production process, it is characterized in that, this wear-resistant waterproof cloth production process comprises base cloth making, base cloth dyeing, waterproof coating material feeding, wear-resistant coating coating materials and cleaning and cutting;

[0026] Wherein, the production of the base fabric includes winding, warping, sizing, reeding, weaving and finishing, and the specific steps are as follows:

[0027] A. Winding: Firstly, the raw yarn shipped from the spinning mill is made into a larger-capacity bobbin, and then the yarn is inspected to remove yarn defects, so that the yarn is wound into a uniform and solid bobbin under a certain tension for warping The tension of the warp yarn is consistent, which is convenient for the warping work in the next step;

[0028] B. Warping: According to the process design requirements, a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com