Composite paste for disperse printing and preparation method thereof

A dispersion and paste technology, applied in the field of textile printing and dyeing, can solve the problems of limited source of raw materials, low hair removal rate, insufficient permeability, etc., and achieve the effects of good water solubility, convenient use and good levelness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

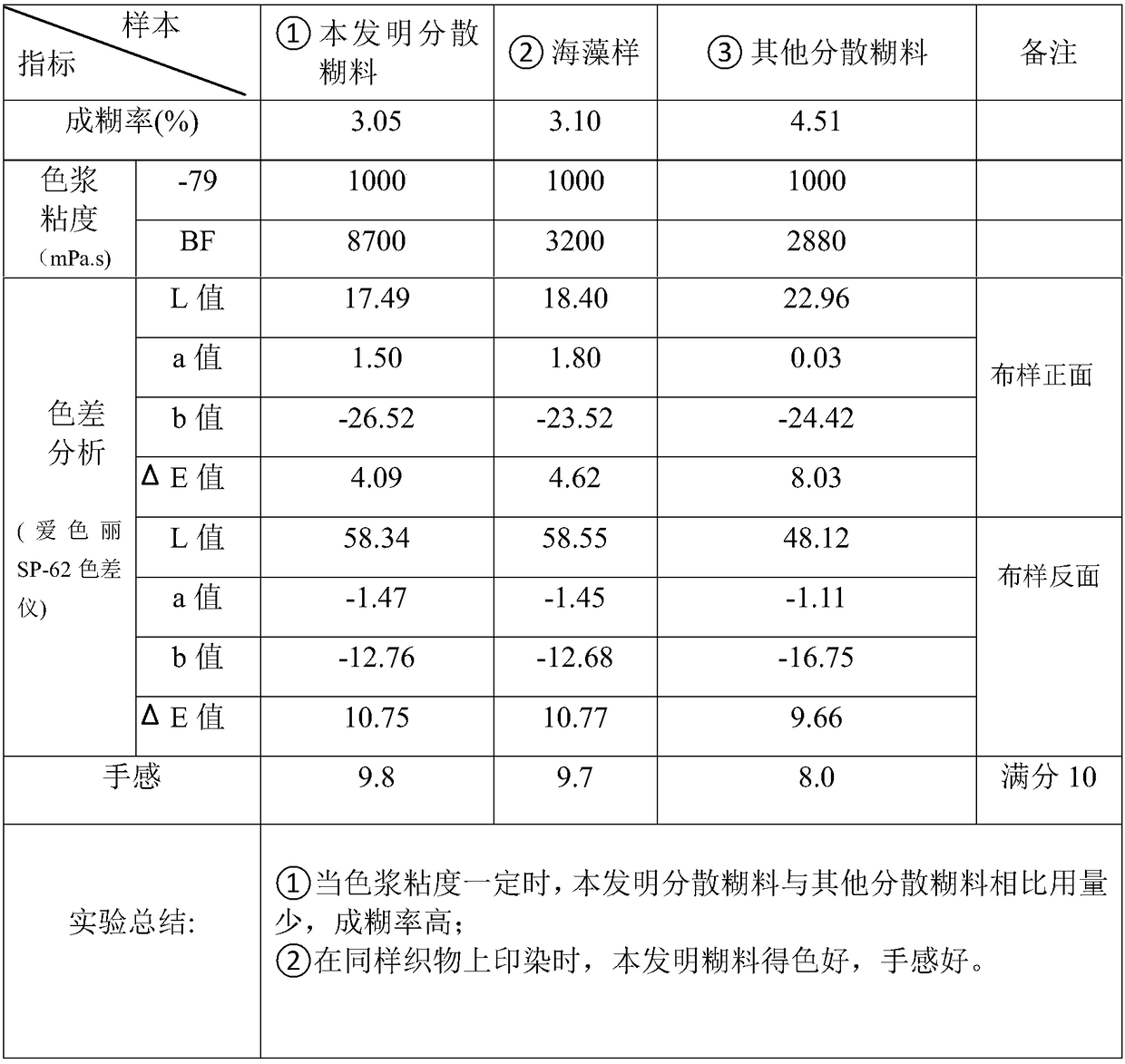

Image

Examples

Embodiment 1

[0051] This embodiment discloses a preparation method of a composite paste for disperse printing, comprising the following steps:

[0052] 1) Dissolving 500kg cornstarch and 300kg tamarind gum into 3200kg of ethanol with a concentration of 93%, stirring evenly, then adding liquid caustic soda with a solid content of 30%, adjusting the pH of the reaction system to be 11~12, the alkali The amount of solution used is about 85kg, the temperature of the reaction system is adjusted to 30°C, and the activation reaction takes 30 minutes to obtain the first intermediate product;

[0053] 2) Add 2.4kg of cross-linking agent phosphorus oxychloride to the first intermediate product in step 1), control the reaction temperature to 30°C, and cross-link for 30 minutes to obtain the second intermediate product;

[0054] 3) Slowly and uniformly add 440kg of chloroacetic acid to the second intermediate product in step 2), control the temperature of the reaction system≤45°C, then slowly and uniform...

Embodiment 2

[0058] This embodiment discloses a preparation method of a composite paste for disperse printing, comprising the following steps:

[0059] 1) Dissolving 500kg potato starch and 350kg tamarind gum into 3200kg of ethanol with a concentration of 93%, stirring evenly, then adding liquid alkali with a solid content of 31%, adjusting the pH of the reaction system to be 11~12, the alkali The amount of solution used is about 93kg, the temperature of the reaction system is adjusted to 30°C, and the activation reaction takes 30 minutes to obtain the first intermediate product;

[0060] 2) Add 3.4kg of cross-linking agent epichlorohydrin to the first intermediate product in step 1), control the reaction temperature to 30°C, and cross-link for 30 minutes to obtain the second intermediate product;

[0061] 3) Slowly and uniformly add 440kg of chloroacetic acid to the second intermediate product in step 2), control the temperature of the reaction system≤45°C, then slowly and uniformly add 3...

Embodiment 3

[0065] This embodiment discloses a preparation method of a composite paste for disperse printing, comprising the following steps:

[0066] 1) Dissolving 400kg wheat starch and 400kg tamarind gum into 3000kg of ethanol with a concentration of 93%, stirring evenly, then adding liquid caustic soda with a solid content of 30.5%, adjusting the pH of the reaction system to be 11~12, the alkali The amount of solution used was about 83kg, the temperature of the reaction system was adjusted to 30°C, and the activation reaction was performed for 30 minutes to obtain the first intermediate product;

[0067] 2) Add 4.0 kg of cross-linking agent phosphorus oxychloride to the first intermediate product in step 1), control the reaction temperature to 30°C, and cross-link for 1 hour to obtain the second intermediate product;

[0068] 3) Slowly and uniformly add 400kg of chloroacetic acid to the second intermediate product in step 2), control the temperature of the reaction system to ≤45°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com