A drilling-free construction method for blasting demolition of reinforced concrete frame structures

A technology of reinforced concrete and construction method, applied in blasting and other directions, can solve the problems of difficulty in ensuring the accuracy of network connection for hole blasting, increase in construction cost, and increase in labor cost, and achieve low construction cost, reduced bearing capacity, and simple construction process. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0039] see Figure 4 , a drilling-free construction method for blasting demolition of reinforced concrete frame structures, comprising the following steps:

[0040] (1) Formulate the blasting construction plan according to the blasting demolition construction site, environment and other conditions of the reinforced concrete frame structure.

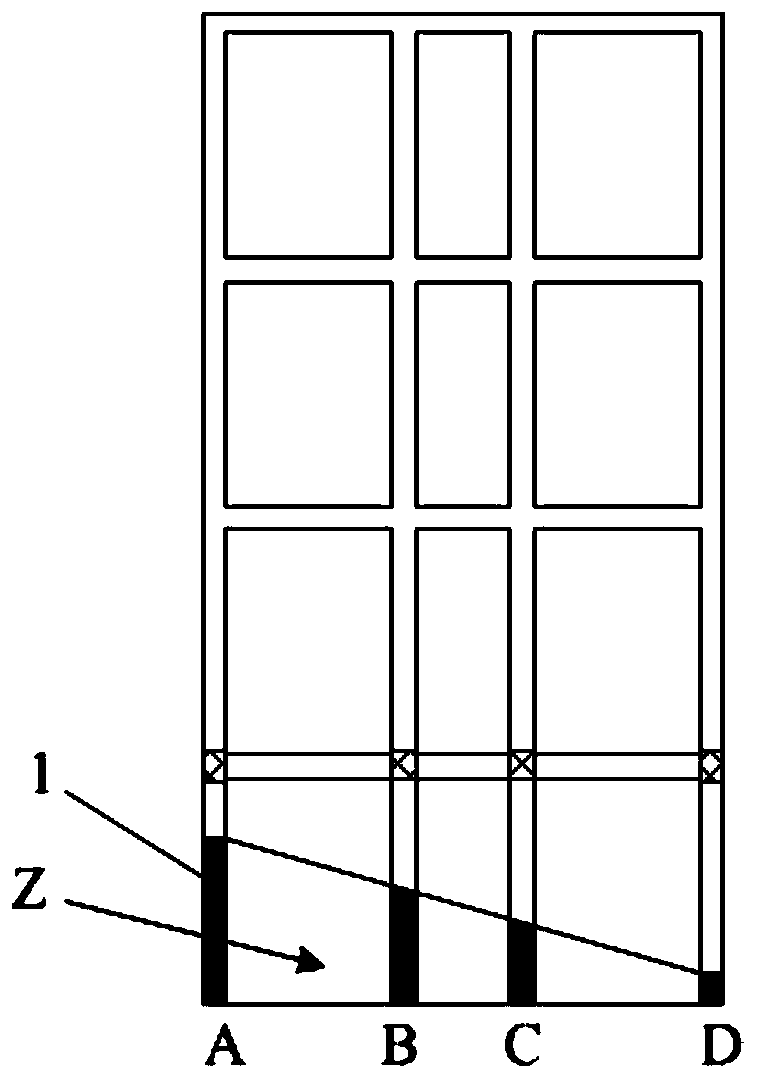

[0041] Specifically, the blasting construction plan is a necessary step for blasting demolition, which can be determined by referring to the corresponding standards and conventional technical parameters, usually including the determination of the dumping direction and the determination of the blasting incision area (see figure 1 ) and the blasting range of beams and columns in the area and the distance from the ground, etc.

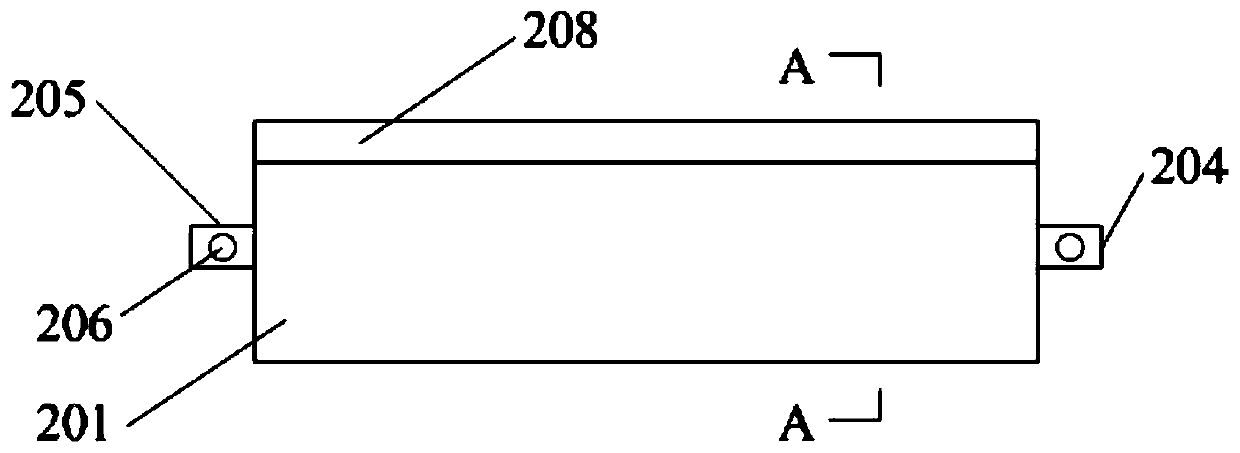

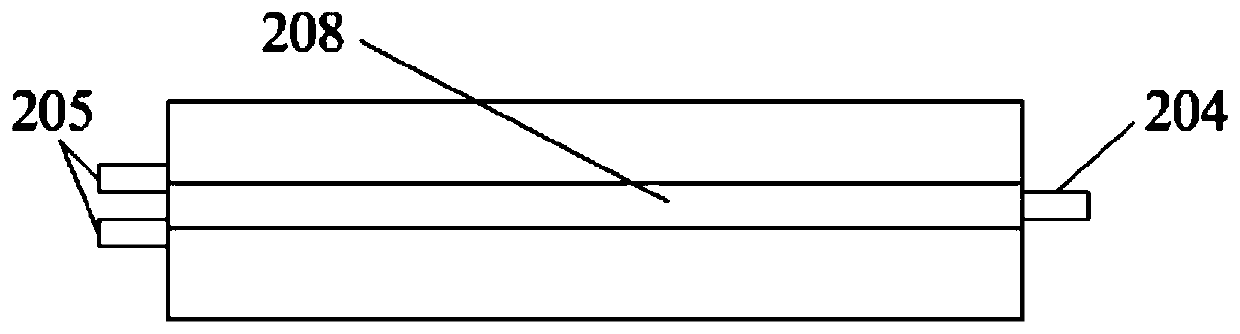

[0042] (2) Make the energy-concentrating cutter 2 according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com