Automatic test system and method for voltage endurance capacity of alternating current contactor

An automatic test system and technology for AC contactors, which are used in circuit breaker testing, dielectric strength testing, etc., can solve the problems of inaccurate test results, slow testing progress, and cumbersome workload, and achieve automatic testing and monitoring. Time synchronization, the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

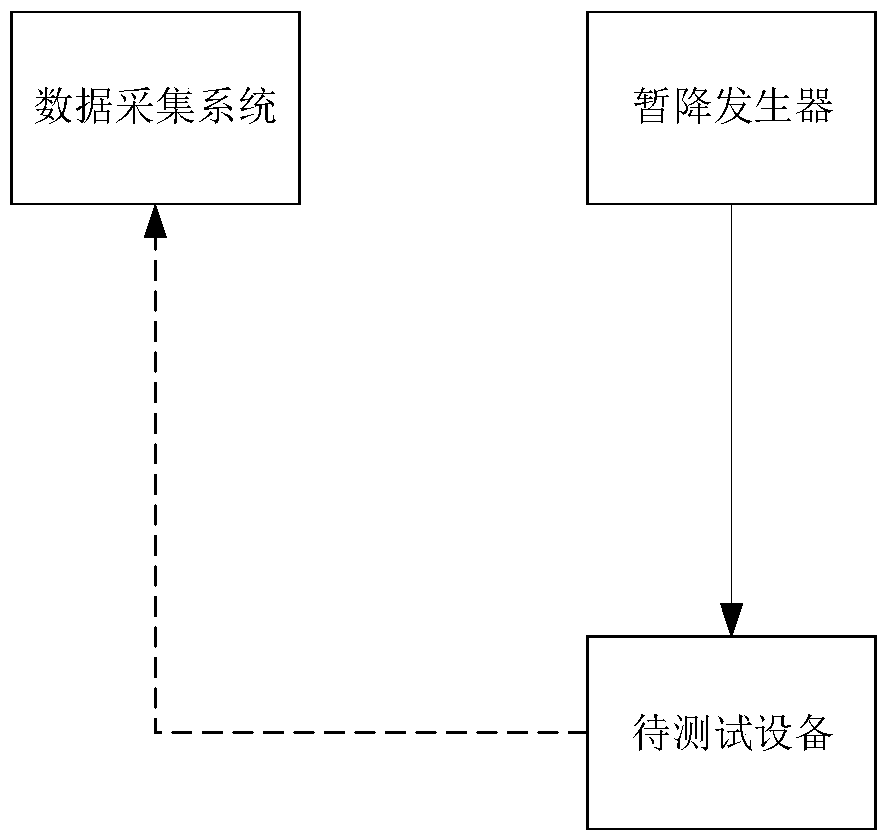

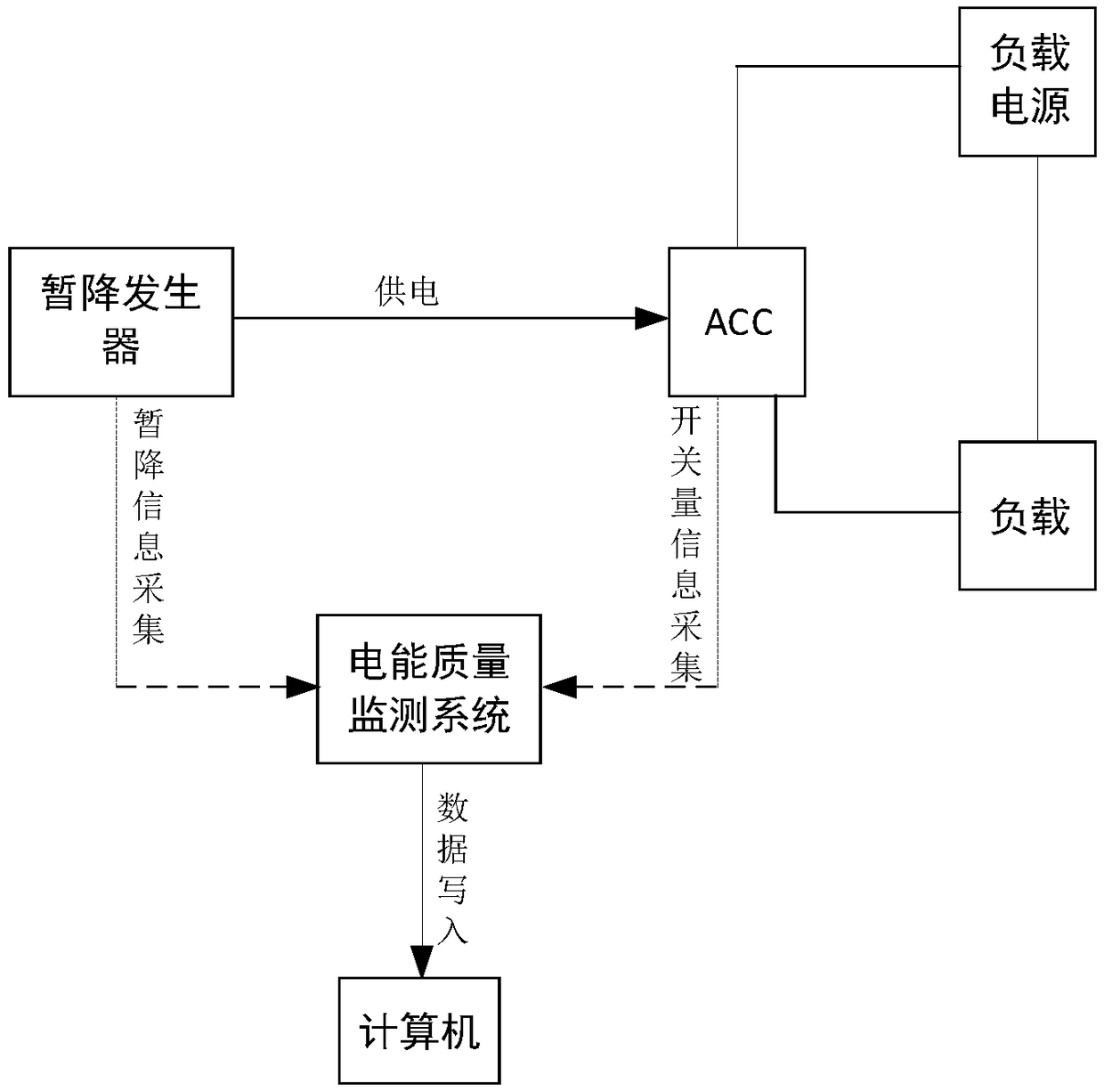

[0088] The sag generator generates a voltage sag signal to supply power to the ACC, and the two channels of the power quality monitoring system collect data.

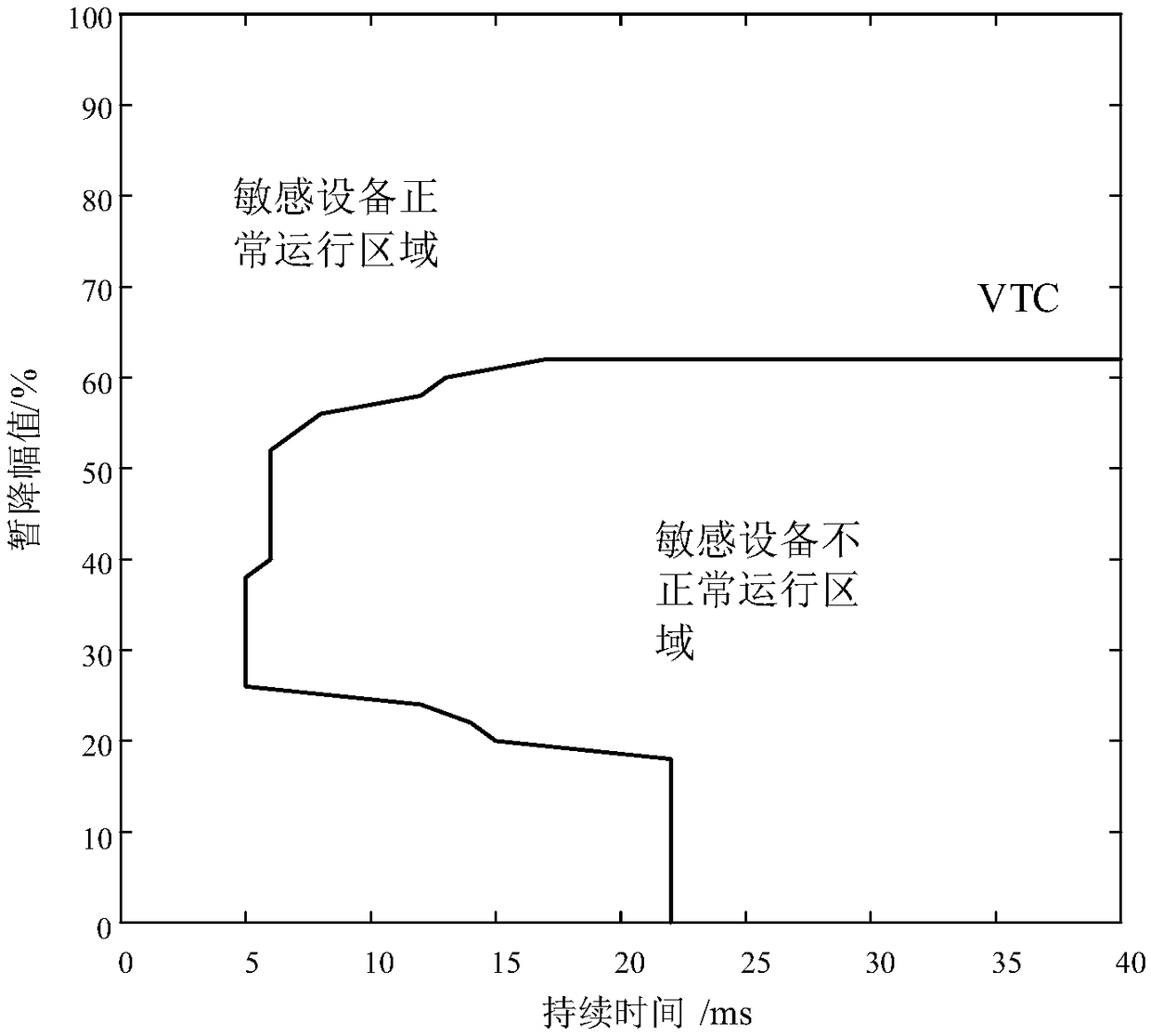

[0089] Channel 1 of the power quality monitoring system monitors the sag generator, and the monitored voltage sag (effective value curve) is as follows: Figure 4 Curve 1, the sag generator generates a signal at time t1, the voltage is at the rated value, the voltage sag occurs at t2, the voltage amplitude drops from 1p.u to Vp.u, the voltage sag ends at t3, and the voltage returns to the rated value.

[0090] t2-t3 is the duration of voltage sag, voltage sag amplitude V(p.u), duration T=t3-t2

[0091] Channel 2 of the power quality monitoring system monitors the switching value of ACC. When the sag generator does not supply power to the ACC (0-t1), the normally open contact of the ACC is disconnected, and the switching value is 0. When the sag generator supplies power to the ACC but no voltage sag occurs (t1-t2), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com