Image sensor and manufacturing method thereof

An image sensor, pixel area technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electro-solid devices, etc., can solve problems such as image quality degradation, easy saturation of white light pixels, and electron overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

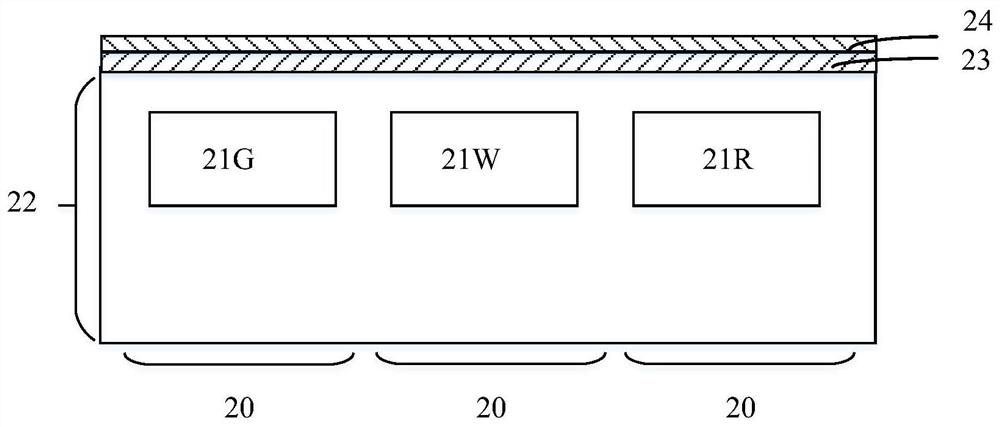

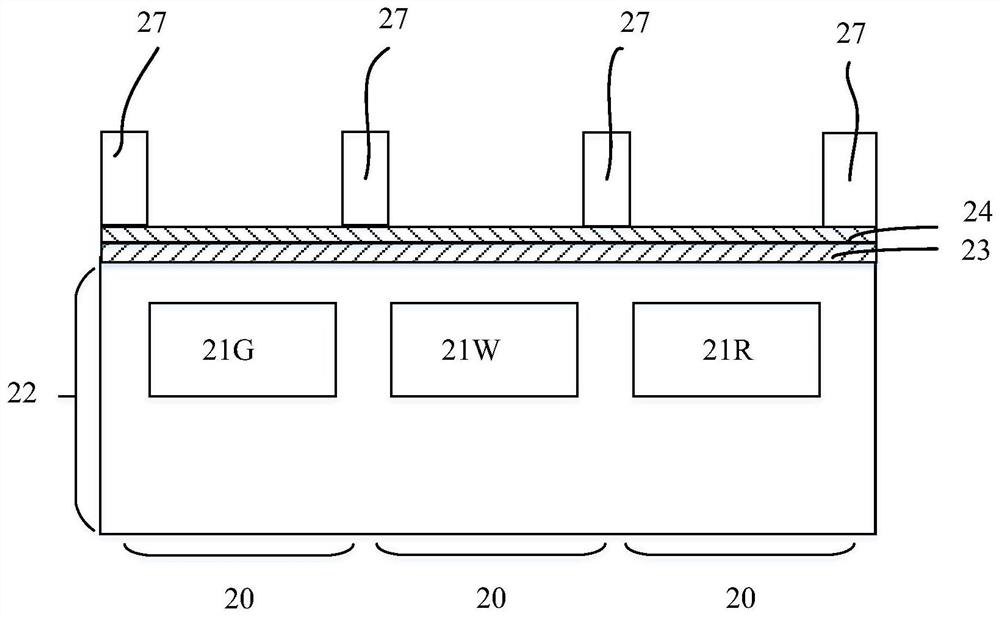

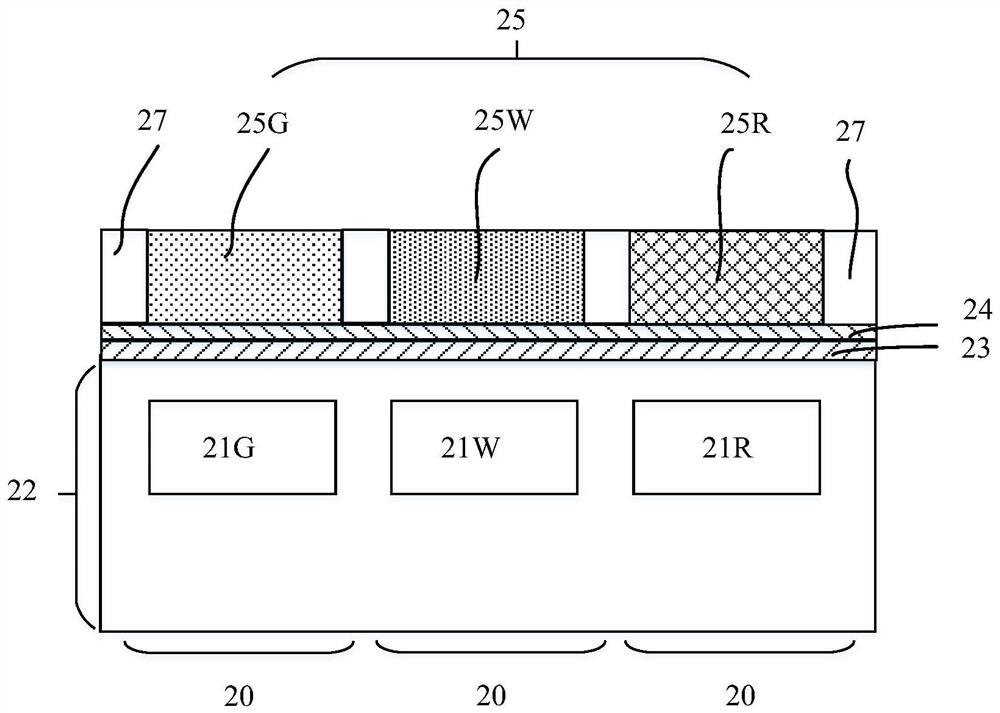

[0043] This embodiment provides an image sensor structure comprising: a semiconductor substrate 22 having a photodiode, the semiconductor substrate 22 comprising a different pixel region 20, wherein the photodiode corresponds to a different pixel region; located in the semiconductor substrate. The upper insulation structure; the light shielding film 27 located on the insulating structure, the light shielding film 27 cover the insulating structure and isolates the different pixel regions 20; the color filter layer 25 corresponding to different pixels is located in the insulating structure. The filter layer 25 includes a white color filter layer 25W; an organic photodiode 28 that blocks the white color filter layer and partially occluded in the white color filter; a microlens 26 located above the color filter layer 25.

[0044] Reference Figure 5 The semiconductor substrate 22 can be a silicon substrate, and may be germanium, silicon, silicon carbide, arsenide or gallium indium, or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com