Device and method for automatic tobacco three-dimensional floating seedling raising

A floating seedling raising and three-dimensional technology, which is applied in botany equipment and methods, horticultural methods, agricultural gas emission reduction, etc., can solve the problems of low degree of automation of floating seedling raising, inability to perform seedling hardening operation, and inability to effectively adjust water and fertilizer supply, etc. Achieve the effect of improving photosynthesis efficiency, reasonable fertilizer amount and fertilization time, and good controllability of humidity environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

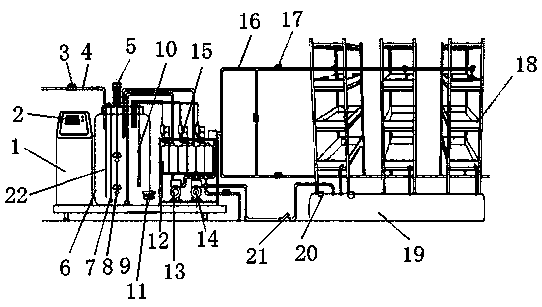

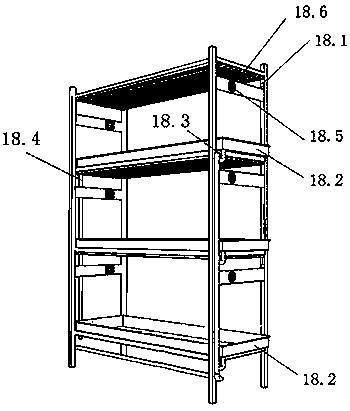

[0037] Such as figure 1 As shown, the automatic tobacco three-dimensional floating seedling raising device of the present embodiment is located in the cultivation room and includes a PLC control system, a nutrient solution circulation system connected to the PLC control system, a lighting system, a temperature and humidity adjustment system and an air circulation system, and a nutrient solution circulation system. The system is connected with 40 hydroponic racks 18, wherein the nutrient solution circulation system includes a liquid storage tank 6, and three nutrient solution raw material tanks 12 communicated with the liquid storage tank 6, respectively adorn different nutrient solution raw materials, and the liquid storage tank 6 The nutrient solution is transported to the inlet of each hydroponic frame 18 by the water outlet pump 13, and the nutrient solution returns to the return bucket 19 after circulating on each hydroponic stand 18, and is drawn back into the liquid stora...

Embodiment 2

[0066] In the automatic three-dimensional floating seedling raising method of tobacco in this embodiment, in step (4), after the seeds germinate, enter the nutrient solution through the PLC system, and the system controls the metering pump to add water and nutrient solution raw materials. When the mixed solution reaches a certain level, The system turns on the stirring device and the ultraviolet disinfection lamp, and at the same time adds the nutrient solution raw materials according to the set EC value and PH value, so that the EC value of the nutrient solution is about 0.25mS / cm, and the prepared nutrient solution is obtained; the tobacco seedlings emerge in 20 days After left and right, increase the concentration of the nutrient solution so that the EC value of the nutrient solution is 0.5mS / cm.

[0067] Through the PLC control system, the indoor temperature is adjusted to about 24°C, the humidity is 60%, and the concentration of carbon dioxide is about 450ppm. Adjust the ...

Embodiment 3

[0069] In the automatic three-dimensional floating seedling raising method of tobacco in this embodiment, in step (4), after the seeds germinate, enter the nutrient solution through the PLC system, and the system controls the metering pump to add water and nutrient solution raw materials. When the mixed solution reaches a certain level, The system turns on the stirring device and the ultraviolet disinfection lamp, and at the same time adds the nutrient solution raw materials according to the set EC value and PH value, so that the EC value of the nutrient solution is 0.3mS / cm, that is, the prepared nutrient solution is obtained; the tobacco seedlings emerge in about 20 days Finally, increase the concentration of the nutrient solution so that the EC value of the nutrient solution is 0.45 mS / cm.

[0070] Through the PLC control system, the indoor temperature is adjusted to about 27°C, the humidity is 70%, and the concentration of carbon dioxide is about 450ppm. Adjust the light i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com