Aseptic canning process and aseptic canning system

A technology of aseptic canning and process method, which is applied in the field of aseptic canning, can solve the problems of slow heat transfer, long heating cycle, and affecting food flavor, etc., and achieve the effect of long storage time, no preservatives, and rich types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

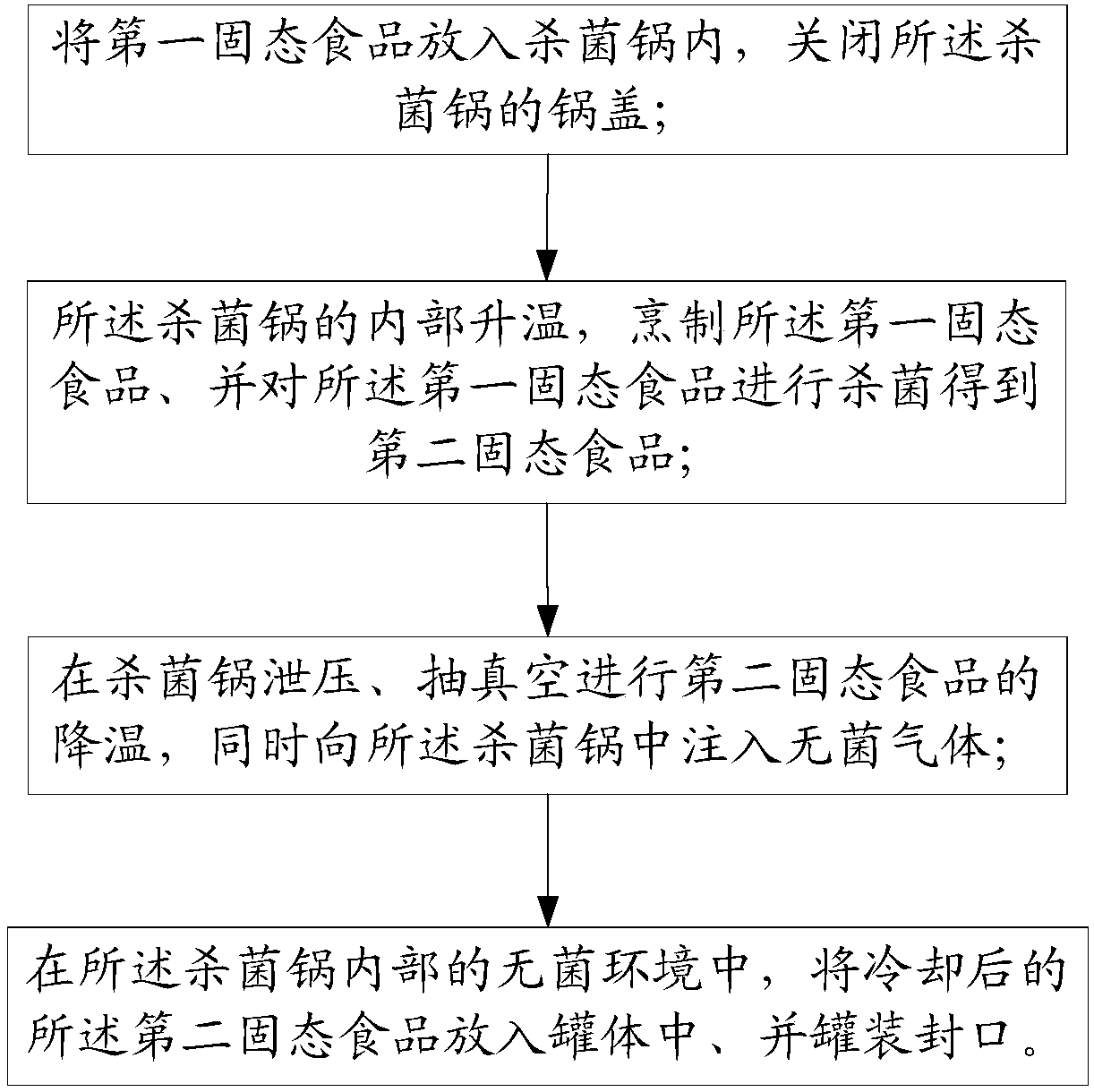

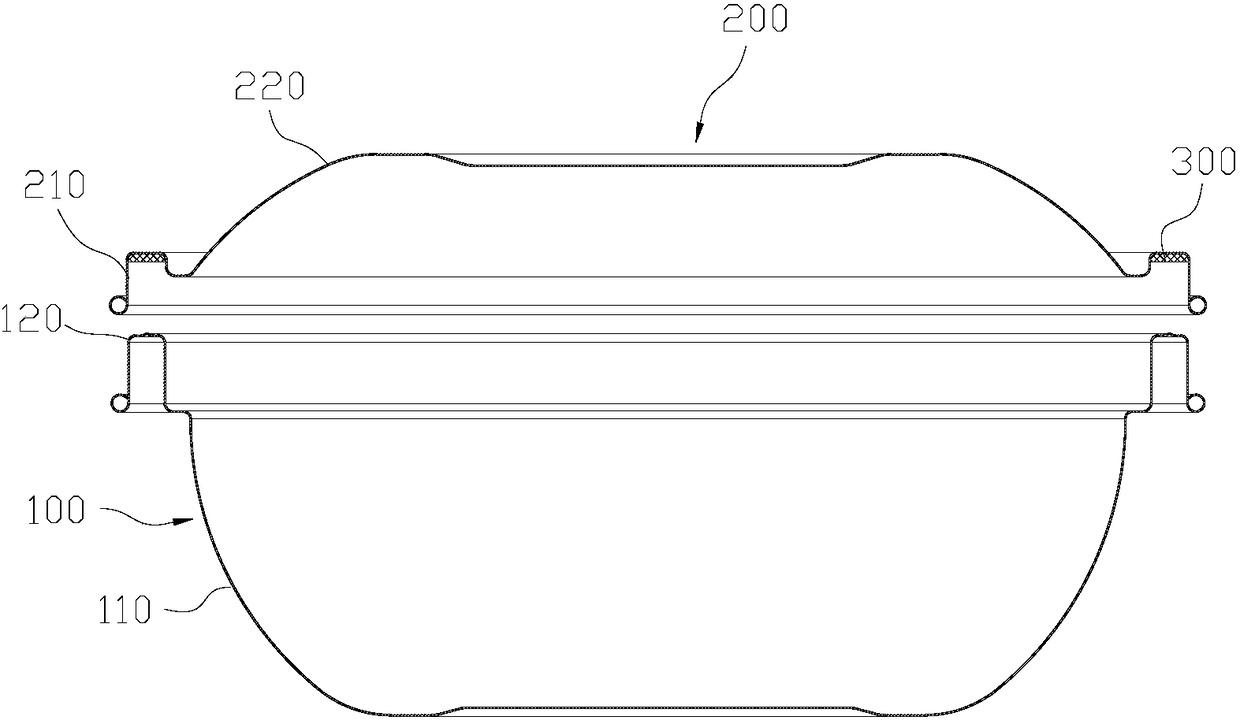

[0056] Put the unpacked first solid food (the first solid food is solid fresh food) into the sterilizer, and close the lid of the sterilizer;

[0057] The internal exhaust of the retort heats up;

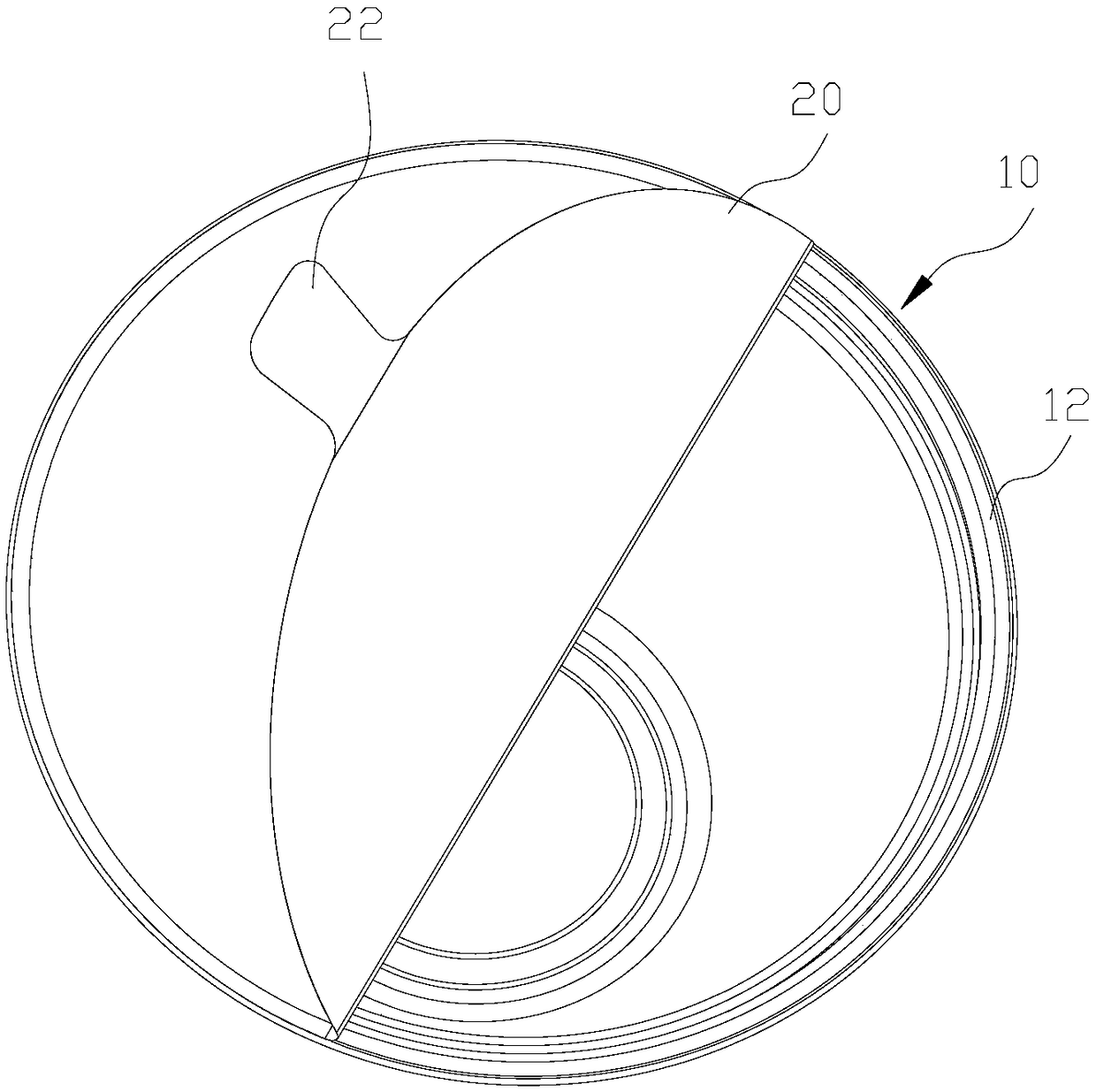

[0058] Put the solid fresh food in a single portion in a small mesh-shaped air-permeable container, and then put it on the conveying device in the retort; or hang the solid fresh food (such as pork ribs, chicken, duck, goose, etc.) Set in the sterilizer so that the steam can directly contact the food, sterilize and cook the solid fresh food at high temperature, so that the obtained second solid food (such as solid steamed cooked food) can reach a sterile state; at the same time, the sterilized The lid and empty cans in the pot are sterilized at high temperature;

[0059] The sterilized second solid food is vacuum cooled in the aseptic environment inside the retort;

[0060] After the second solid food is cooled, fill the sterilization pot with sterile nitrogen or other inert gas; ...

Embodiment 2

[0063] Put the unpacked first solid food (the first solid food is solid fresh food) into the sterilizer, and close the lid of the sterilizer;

[0064] The solid fresh food (such as pork ribs, chicken, duck, goose, etc.) is suspended in the retort, and the heater in the retort is energized to heat, bake, sterilize and cook the solid fresh food to obtain The second solid food (such as solid baked food) also makes the obtained second solid food reach a sterile state; at the same time, high-temperature sterilization is carried out to the can lid and empty can in the sterilizer;

[0065] The sterilized second solid food is vacuum cooled in the aseptic environment inside the retort;

[0066] After the second solid food is cooled, fill the sterilizer with sterile nitrogen or other inert gas;

[0067] In the aseptic environment inside the retort, the cooled second solid food is put into a food press-fit can and sealed tightly to obtain canned food that can be stored at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com