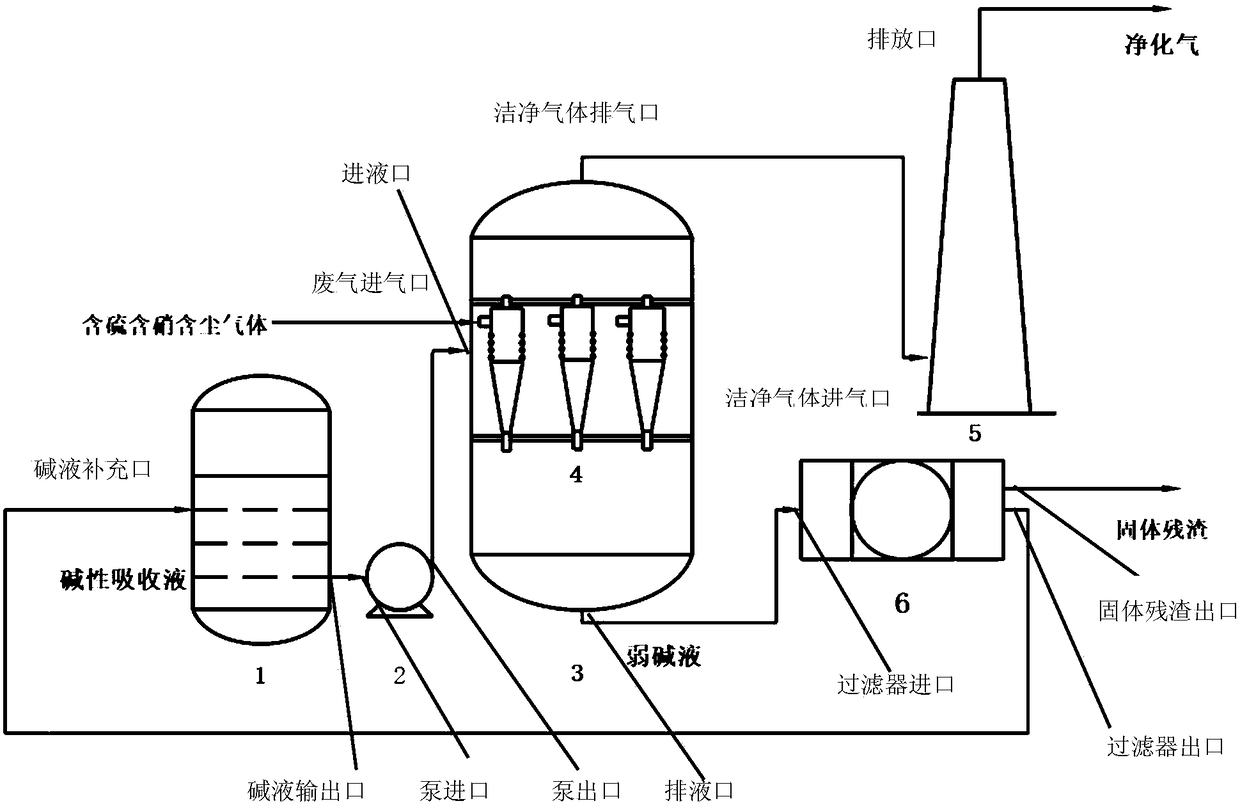

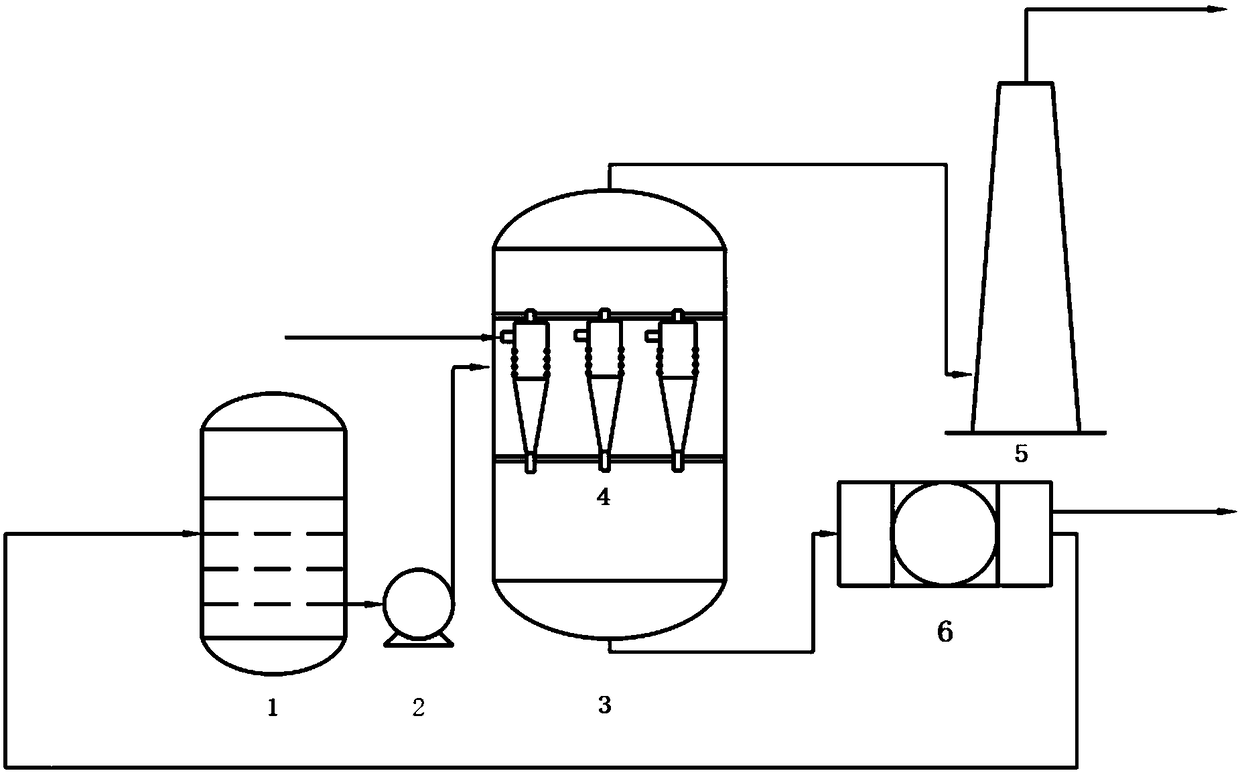

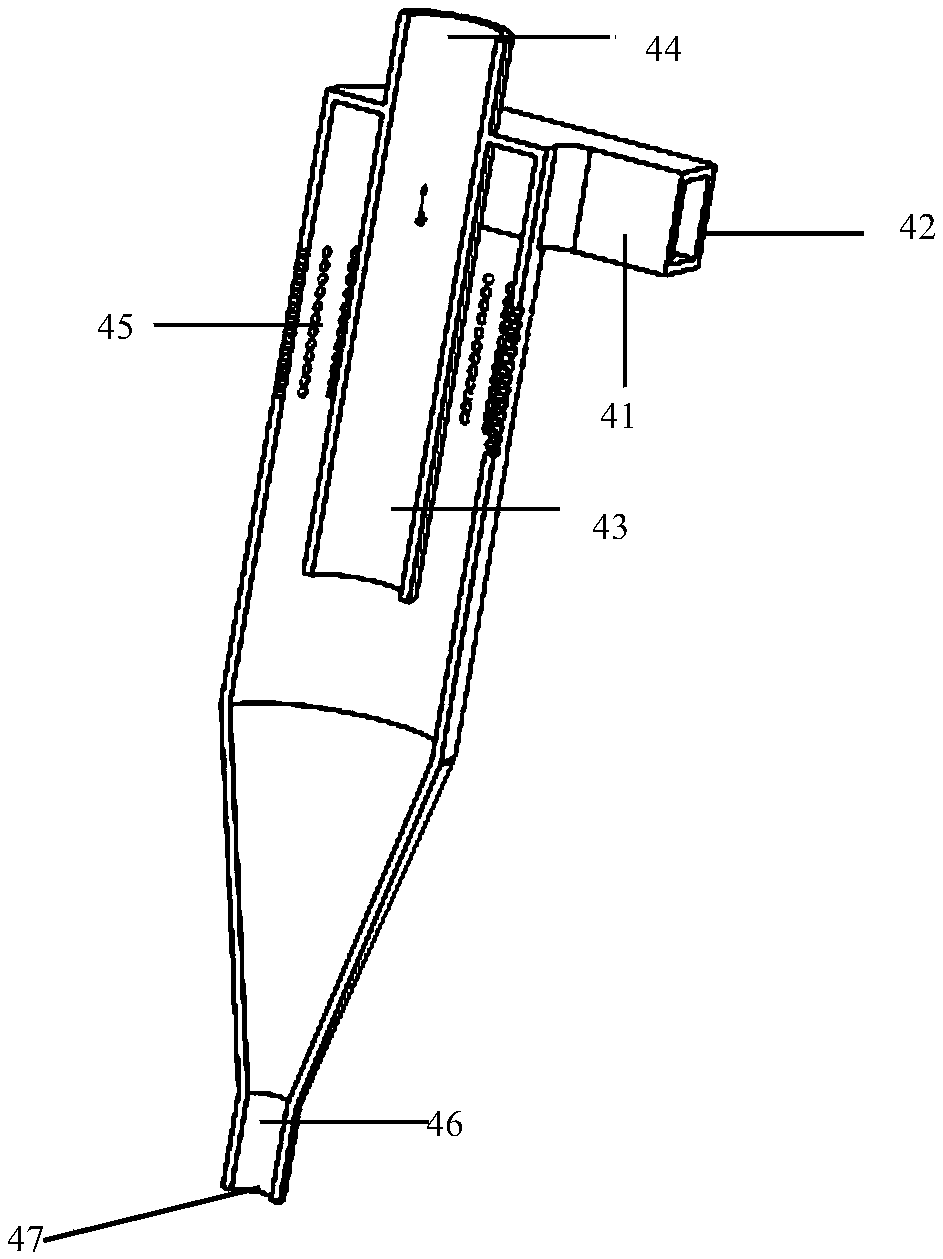

Desulfurization denitrafication dedusting integrated method and device

A desulfurization, denitrification, and denitration technology, which is applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of many components, cumbersome process, low efficiency, etc., to achieve low energy consumption, improve separation and absorption efficiency, and reduce occupation. land area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A petrochemical plant in Hubei 480Nm 3 / h air volume exhaust gas, the concentration of sulfur dioxide is about 3000ppm, the concentration of nitrogen oxides is about 1800ppm, and the content of solid particles is about 260mg / m 3 , according to the process and device of the present invention, using a three-stage vortex absorber, the alkaline absorbent flow rate is 3000kg / h, the sodium hydroxide content is 10%, the sodium hypochlorite content is 10%, and lasts for 24h. After being treated by the above device, the emission of sulfur dioxide is less than 50ppm, the emission of nitrogen oxide is less than 50ppm, and the emission of solid particles is about 20mg / m 3 Below, in line with the "Comprehensive Emission Standards of Air Pollutants" (GB16297-1996), the absorption rate of sulfur dioxide is above 98.3%, the absorption rate of nitrogen oxides is above 97.2%, and the separation efficiency of solid particles is above 92.3%.

Embodiment 2

[0064] A flue gas from a boiler in a power plant has a temperature of 1100°C and 700Nm 3 / h air volume, cooling treatment first, the concentration of sulfur dioxide is about 1500ppm, the concentration of nitrogen oxides is about 1300ppm, and the content of solid particles is about 350mg / m 3 , carried out according to the inventive process and device, and continued for 24 hours. Through the process and device of the present invention, using a three-stage vortex absorber, the alkaline absorbent flow rate is 5000kg / h, the sodium hydroxide content is 12%, the sodium hypochlorite content is 12%, the sulfur dioxide discharge after treatment is below 50ppm, and the nitrogen oxide discharge The amount is about 30ppm or less, and the solid particle emission is about 30mg / m 3 Below, in line with the "Comprehensive Emission Standards of Air Pollutants" (GB16297-1996), the absorption rate of sulfur dioxide is above 96.6%, the absorption rate of nitrogen oxides is above 97.6%, and the sepa...

Embodiment 3

[0066] Into the above-mentioned device, feed the sulfur dioxide with a concentration of 1000ppm, the nitrogen oxide with a concentration of 1000ppm, and the solid particle content is 500mg / m 3 The flue gas lasts for 24h; through the process and device of the present invention, a single-stage eddy current absorber is used, and the gas flow rate is 10m 3 / h, the flow rate of alkaline absorbent is 150L / h, the content of sodium hydroxide is 0.6%, the content of sodium hypochlorite is 0.6%, the discharge of sulfur dioxide after treatment is below 20ppm, the discharge of nitrogen oxide is below 20ppm, and the discharge of solid particles is about 20mg / m 3 Below, in line with the "Comprehensive Emission Standards of Air Pollutants" (GB16297-1996), the absorption rate of sulfur dioxide is above 98%, the absorption rate of nitrogen oxides is above 98%, and the separation efficiency of solid particles is above 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com