A crushing and refining device for reuse of concrete blocks

A concrete block and crushing box technology, applied in the field of construction machinery, can solve the problems of insufficient and thorough concrete crushing effect and insufficient refinement degree, and achieve the effect of improving the grinding effect, promoting the degree of refinement, and increasing the crushing range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

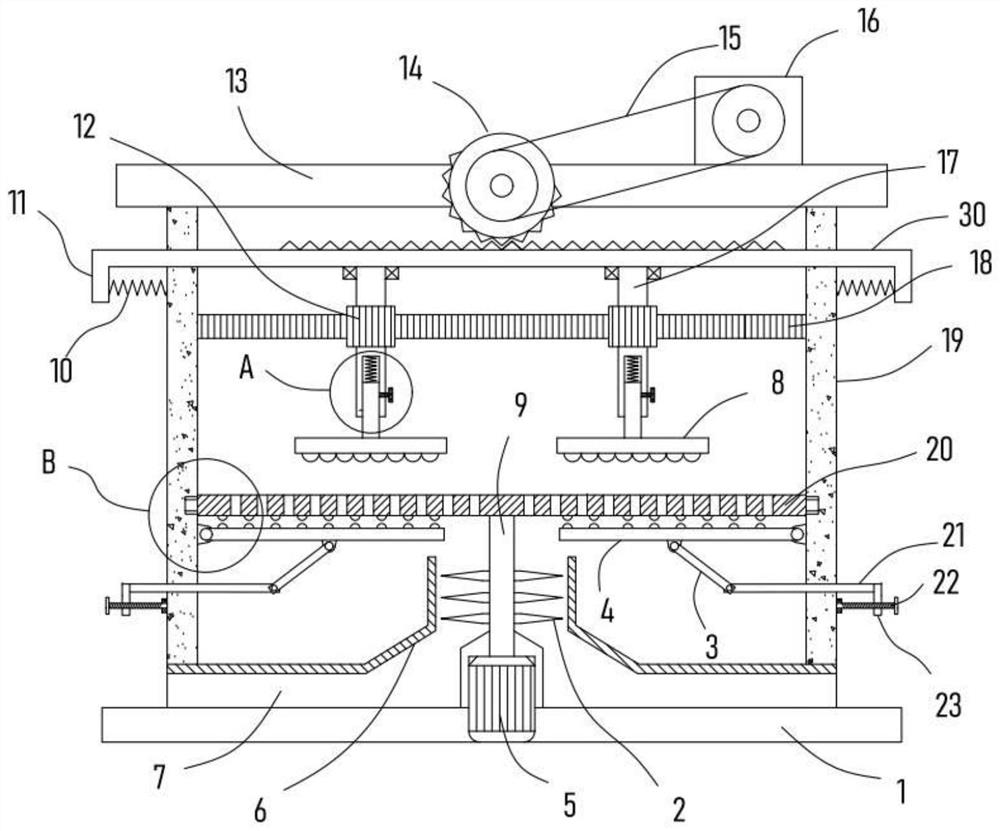

[0022] see Figure 1-3 , a crushing and refining device for reuse of concrete blocks, comprising a base 1 and a crushing box 19 fixed on the base 1, a top plate 13 is fixed on the crushing box 19, and a sieve tray 20 is horizontally rotated in the crushing box 19, Two crushing platens 8 are rotated above the sieve tray 20, and the crushing box 19 is an open structure, and the crushing box 19 is used as a container for crushing concrete blocks, and the concrete blocks placed in the crushing box 19 fall on the sieve tray 20.

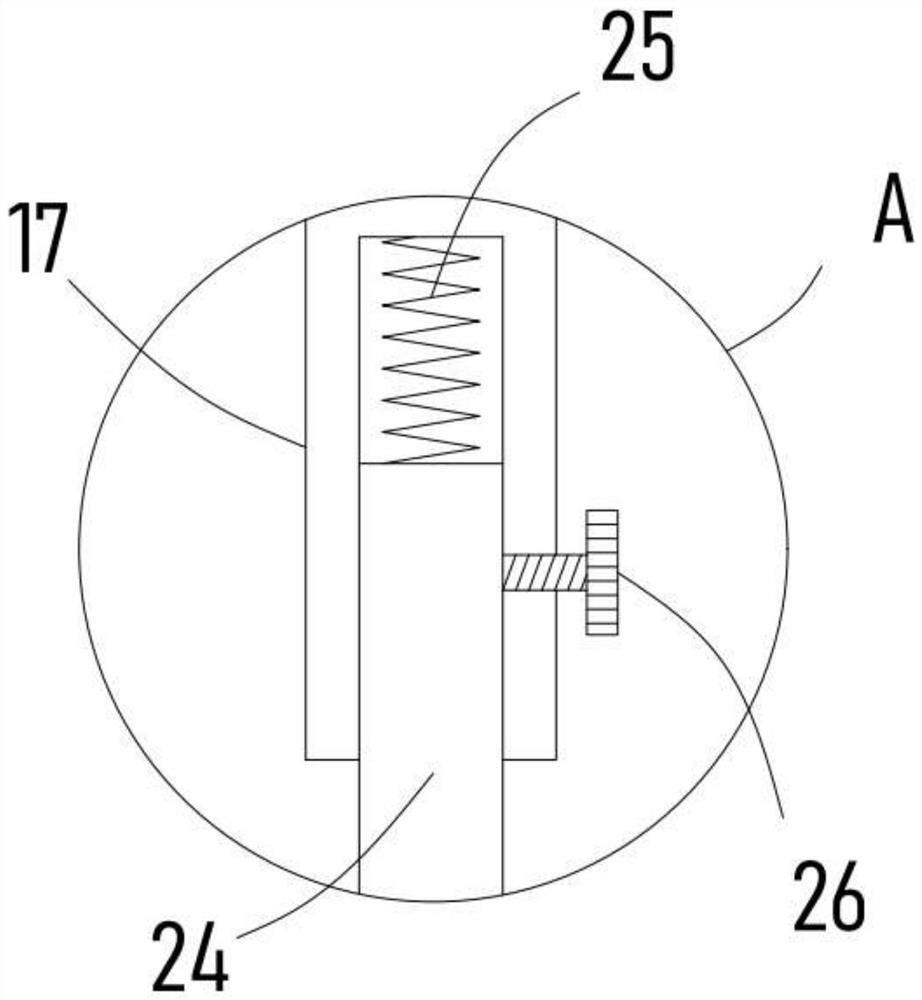

[0023] A spur rack II30 is installed horizontally in the crushing box 19, and the bottom of the spur rack II30 is pivotally connected with a transmission sleeve 17 fixedly connected with the crushing platen 8. The transmission sleeve 17 is sleeved and fixed with a cylindrical spur gear 12. 19 is horizontally fixed with a spur rack I18 meshing with the cylindrical spur gear 12, and a motor I5 is fixed on the base 1, and the output shaft of the motor I5 is c...

Embodiment 2

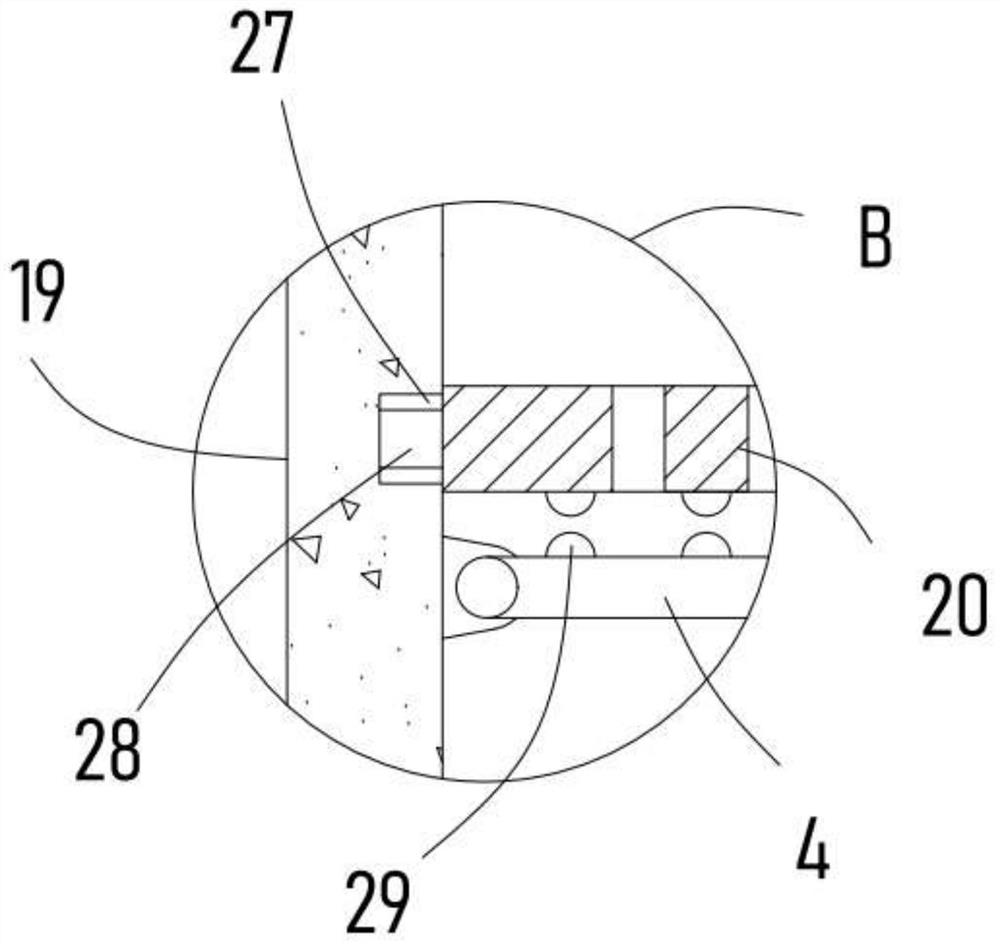

[0030] On the basis of Embodiment 1, in addition, the grinding bottom plate 4 located at the bottom of the sieve pan 20 is hinged on the inner wall of the crushing box 19, and several grinding projections 29 are fixed on the upper surface of the grinding bottom plate 4 and the bottom surface of the sieve pan 20.

[0031] During the rotation process of the sieve pan 20, the more fully ground concrete blocks pass through the sieve holes on the sieve pan 20 and fall on the grinding bottom plate 4, and the relative sliding between the sieve pan 20 and the grinding bottom plate 4 realizes further grinding of the concrete by the grinding projections 29. Grinding and refining greatly improves the degree of crushing.

[0032] Further, the inner side wall of the crushing box 19 is provided with a circumferential limit groove 27, and the side wall of the sieve tray 20 is fixed with a transmission ring plate 28 slidably embedded in the circumferential limit groove 27. During the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com