Cork wood concentrate production process

A production process and cork technology, applied in solid separation, sieves, grilles, etc., can solve the problems of low production efficiency, poor dustproof effect, and large environmental impact in the production process, and achieve good dustproof effect and high production efficiency. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

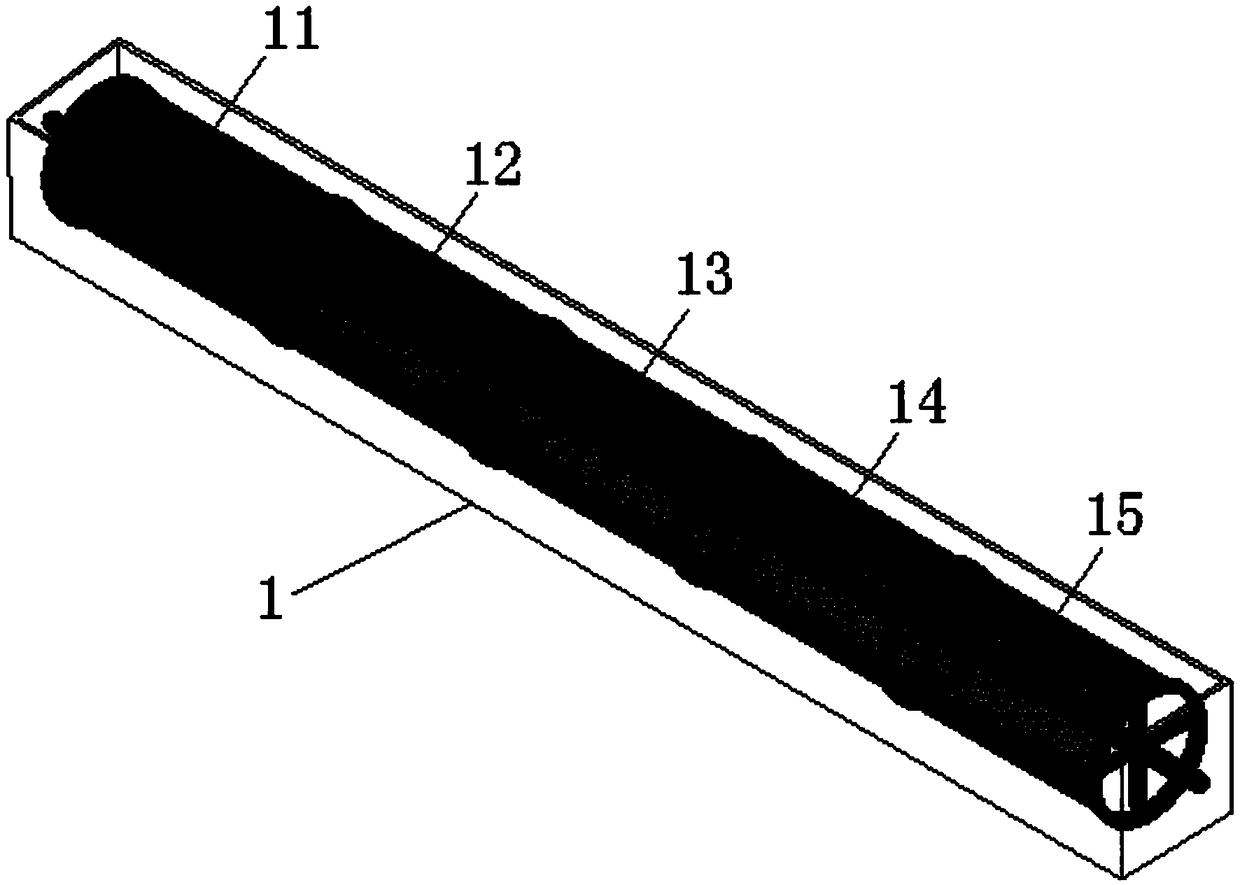

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and embodiment the invention is further described:

[0009] The production steps of the cork concentrate production process of the present invention include: selecting cork bark, pulverizing it into rough granules through a pulverizer, and then sending it into a disc mill to remove the old skin to obtain primary granules, and then entering the vibrating sieve for primary granules. Granular material sorting, further remove impurities, and obtain pure granular material, which is then sent to the cyclone separator for separation to obtain fine particles, and then sent to the grinder to grind into fine granular material, and then sent to the material bag for packaging.

[0010] Described cork bark is cork oak bark. The particle size of the hair particles is 1 mm-12 mm, and the particle size of the fine particles is 4 mesh to 32 mesh. The pulverizer is a chip pulverizer, the disc grinder is a conical disc grinder or a flat disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com