Rotary printing electrolytic machining liquid sealing device and method

A non-processing area, flushing technology, applied in electric processing equipment, electrochemical processing equipment, accessories, etc., can solve the problems of divergent flow field, poor flow field distribution, and small flow rate of electrolyte, and achieve increased flow rate, Improve the effect of flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Implementation of the present invention - "Spin Printing Electrolytic Machining Liquid Sealing Device and Method"

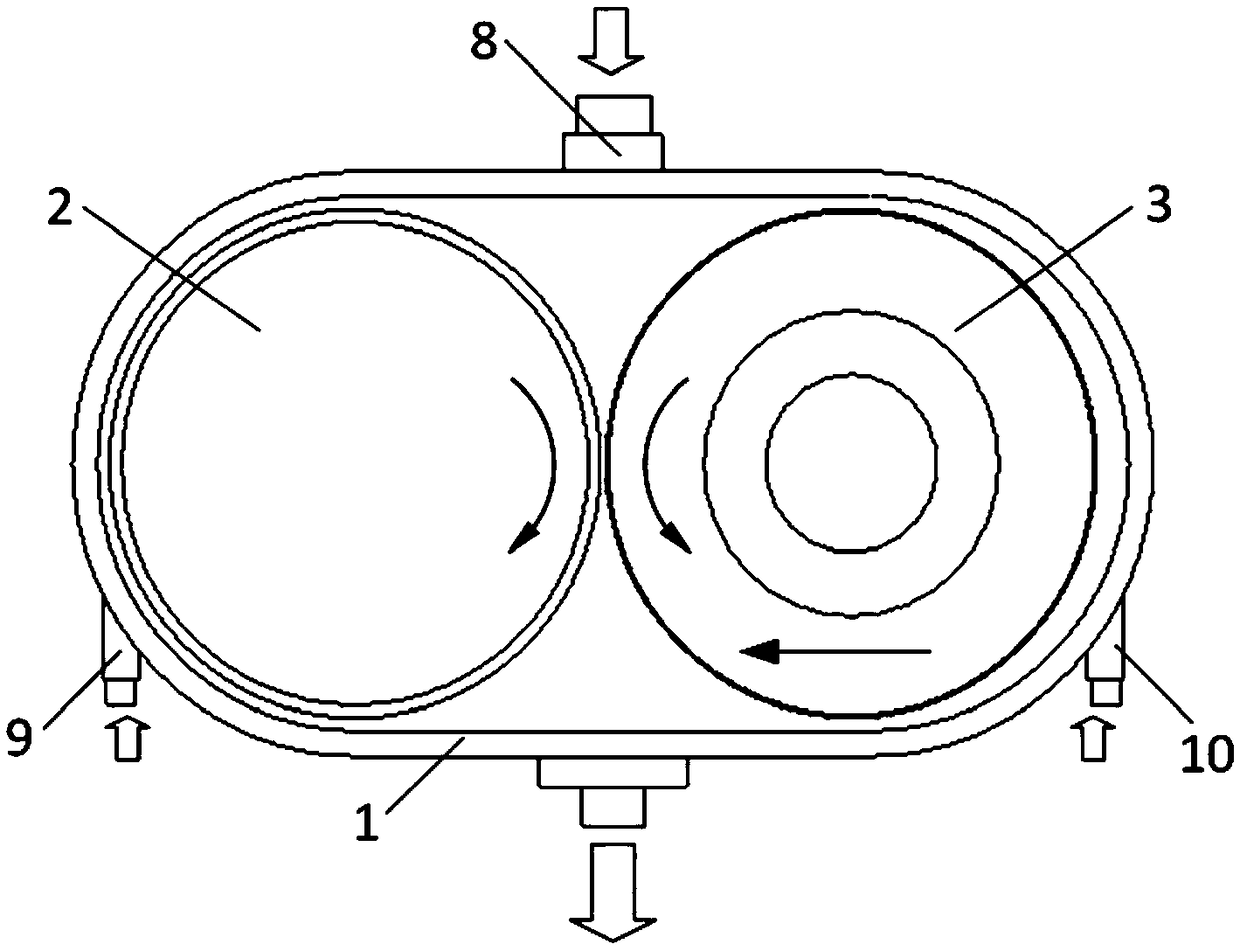

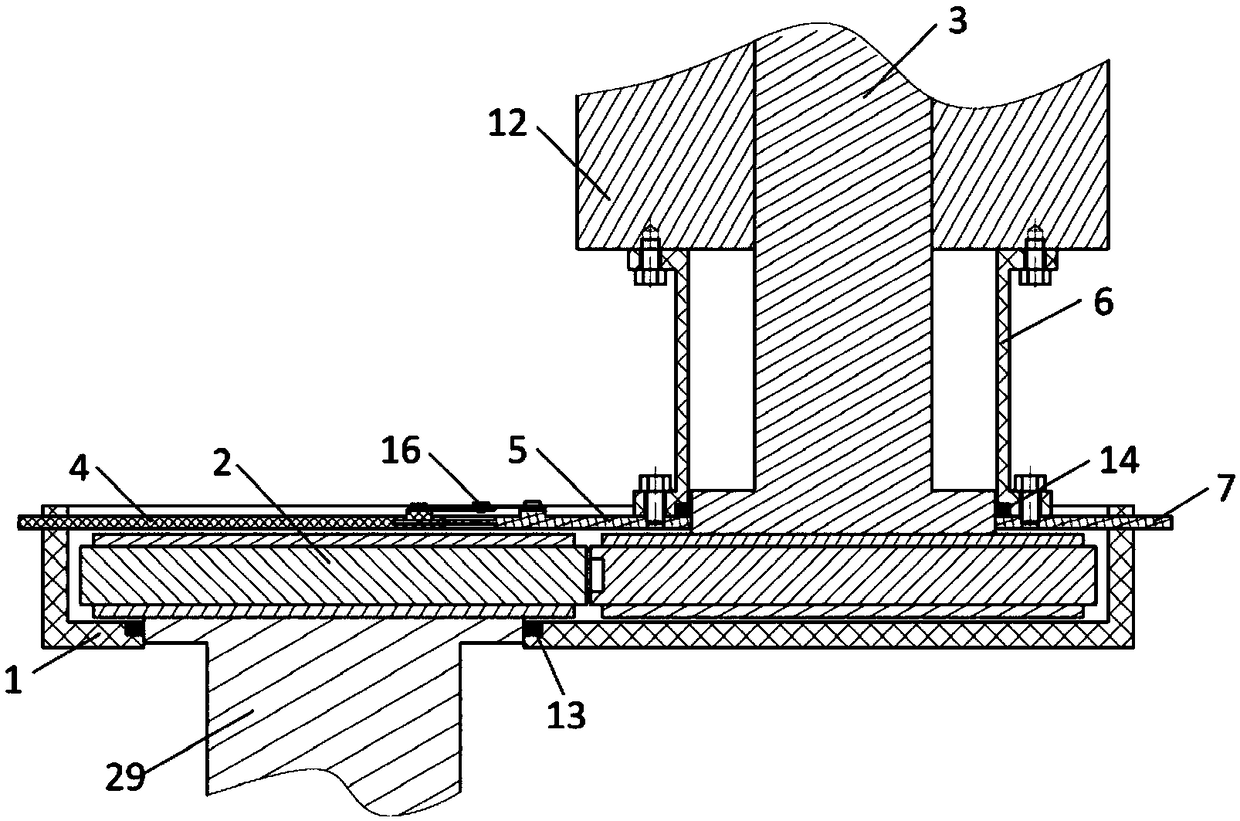

[0027] Such as figure 1 , 2 As shown, the device includes a flushing fixture seat, an auxiliary sealing sleeve, a fixed cover, a retractable cover, a follower cover, a tool cathode unit, a workpiece unit, and a workpiece rotating spindle.

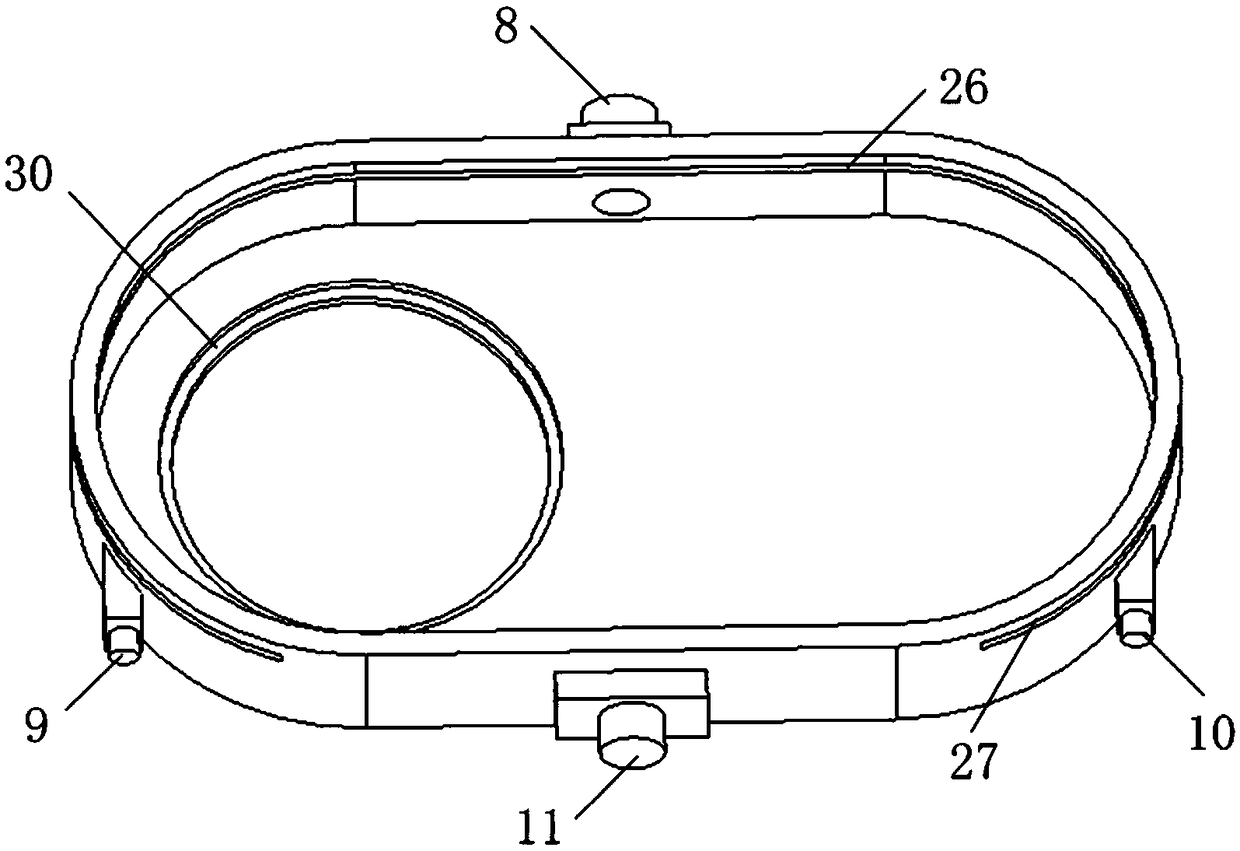

[0028] Such as image 3 As shown, the flushing fixture seat has a main flushing port, a left auxiliary flushing port, a right auxiliary flushing port and a liquid outlet. The main flushing port faces the processing area and flushes from back to front; the left auxiliary flushing port The flushing port and the right auxiliary flushing port are respectively facing the center of the left and right non-processing areas, flushing from front to back, and the flushing pressure of the auxiliary flushing port is not less than the flushing pressure of the main flushing port. The left and right side walls of the flushing fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com