Automatic packaging bottle perforating machine based on photoelectric detecting and positioning

A photoelectric detection and packaging bottle technology, which is applied in metal processing and other directions, can solve the problems of easy dislocation of bottle caps, poor discharge hole precision, and high labor intensity, so as to improve market competitiveness, high production efficiency, and low production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

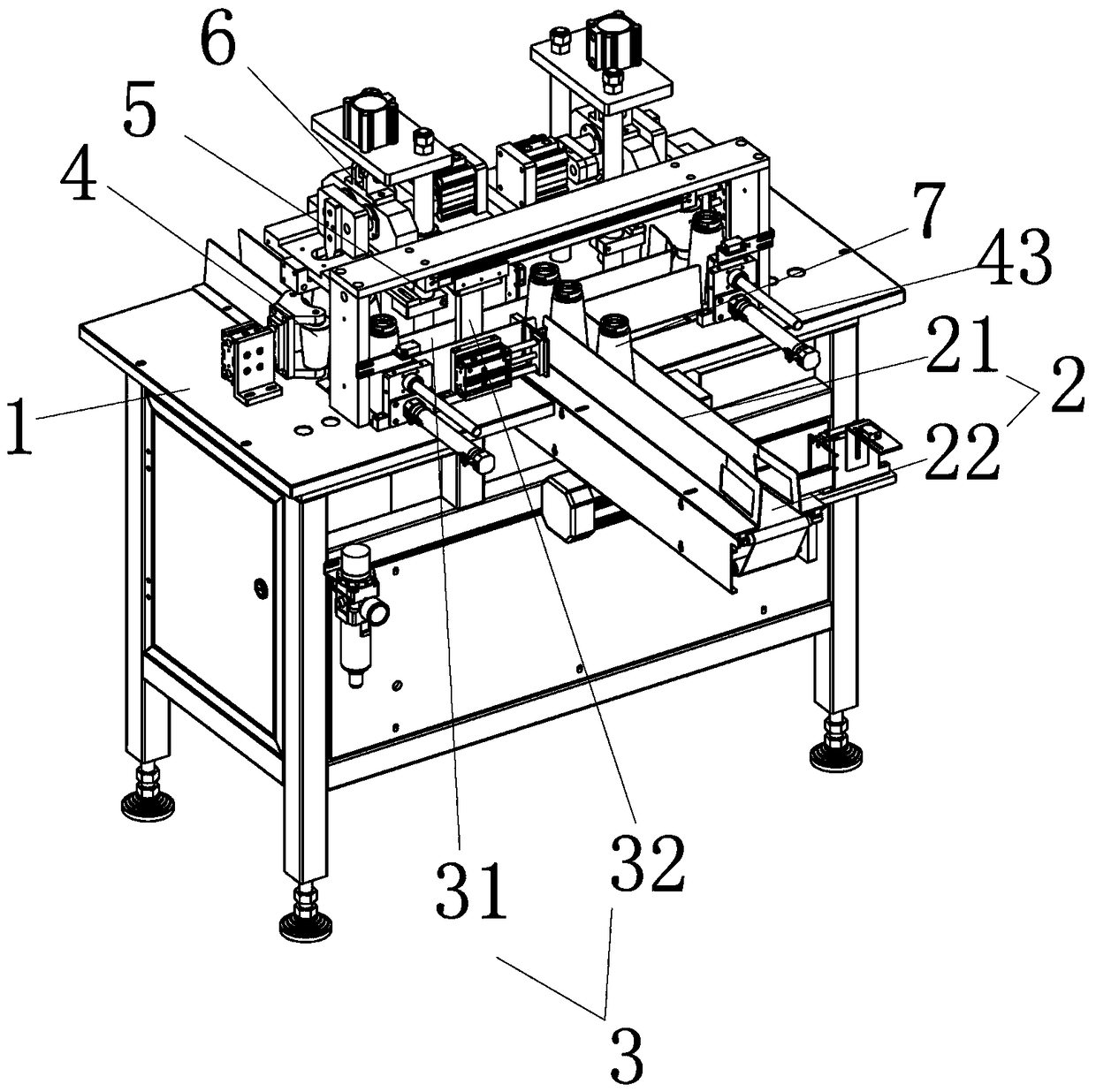

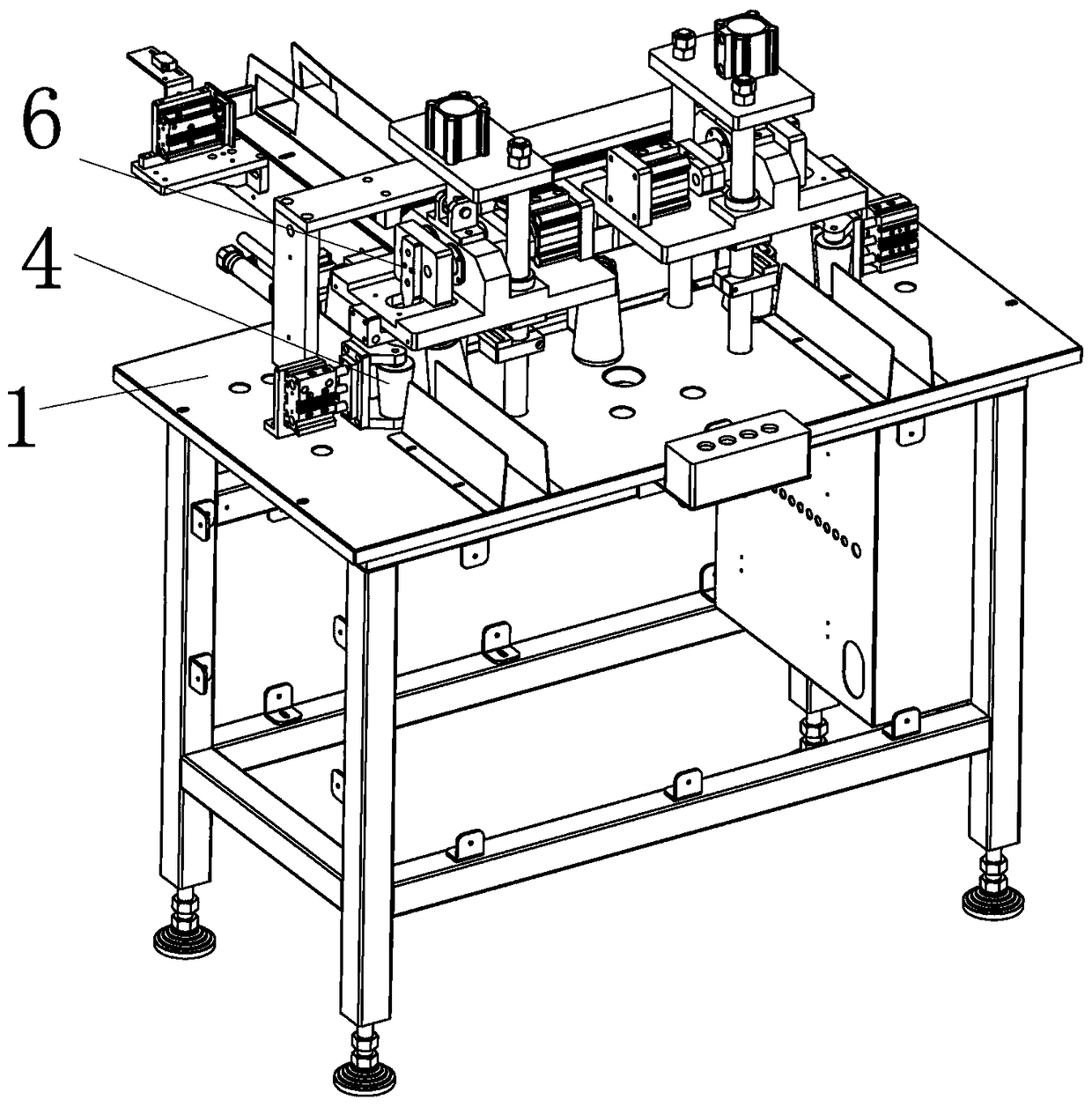

[0026] The present invention will be specifically and further described below in conjunction with the accompanying drawings. An automatic punching machine for packaging bottles based on photoelectric detection and positioning. Hole mechanism 6:

[0027] Wherein, the feeding mechanism 2 includes a material guide plate 21 and a conveyor belt 22 arranged at the bottom thereof, and the packaging bottle 7 is placed in the material guide plate 21 by manual or mechanized equipment, and is sent into the material guide plate 22 by the conveyor belt 22. Distributing mechanism 3;

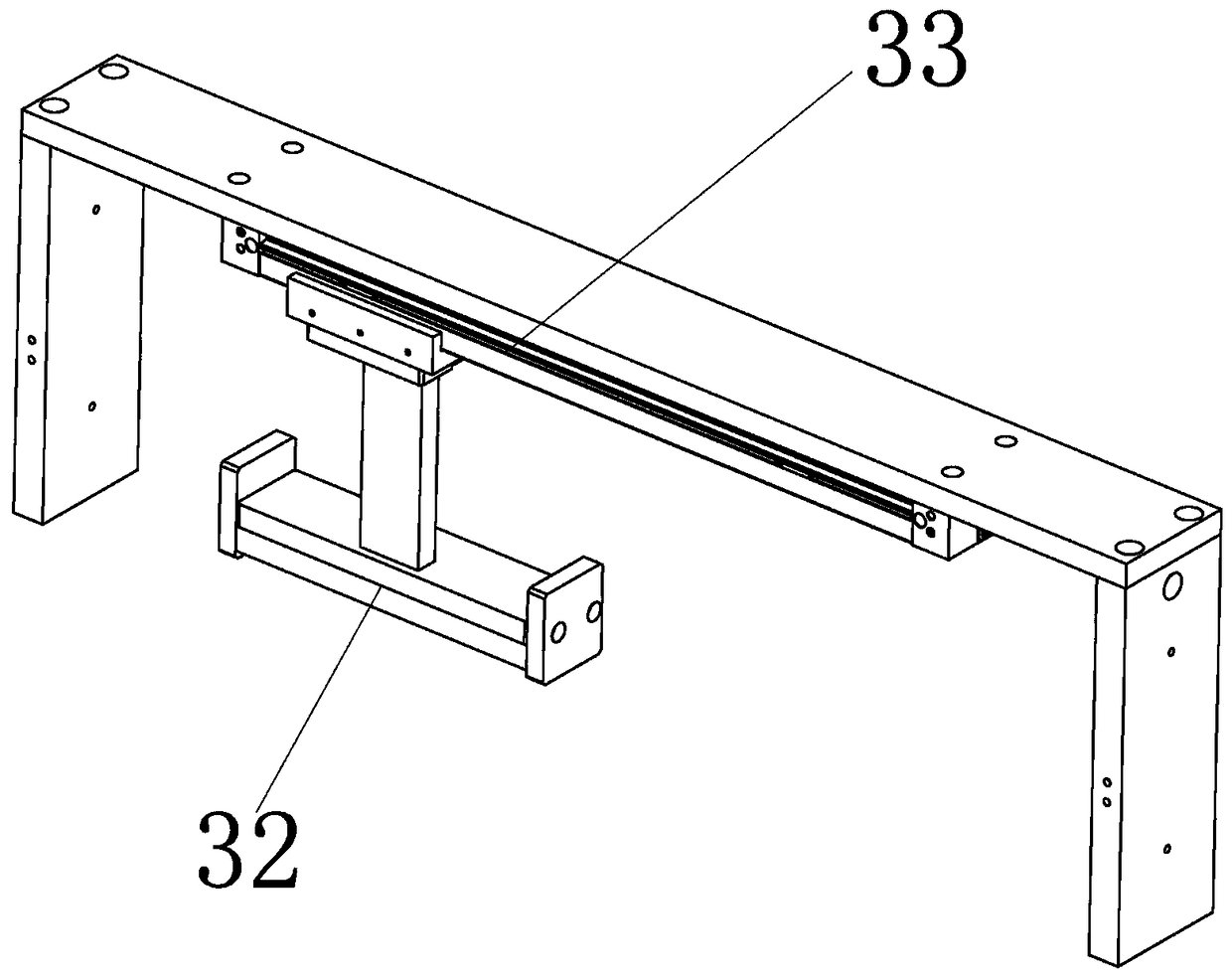

[0028] The material distributing mechanism 3 includes a material distributing slideway 31 and a push plate 32 arranged therein, and the push plate 32 is driven by a driving mechanism to slide left and right in the material distributing slideway 31 to push the packaging bottle 7 into position Rotary mechanism 4;

[0029] The positioning and rotating structure 4 includes a driving drive wheel 41 and a driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com