Multifunctional vulcanizer

A vulcanizing machine and multi-functional technology, which is applied to home appliances, belts, and other home appliances, etc., can solve the problems of difficult to achieve overall vulcanization, and cannot make ring-shaped non-interface conveyor belts, etc., to achieve complete functions, improve vulcanization efficiency, and structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

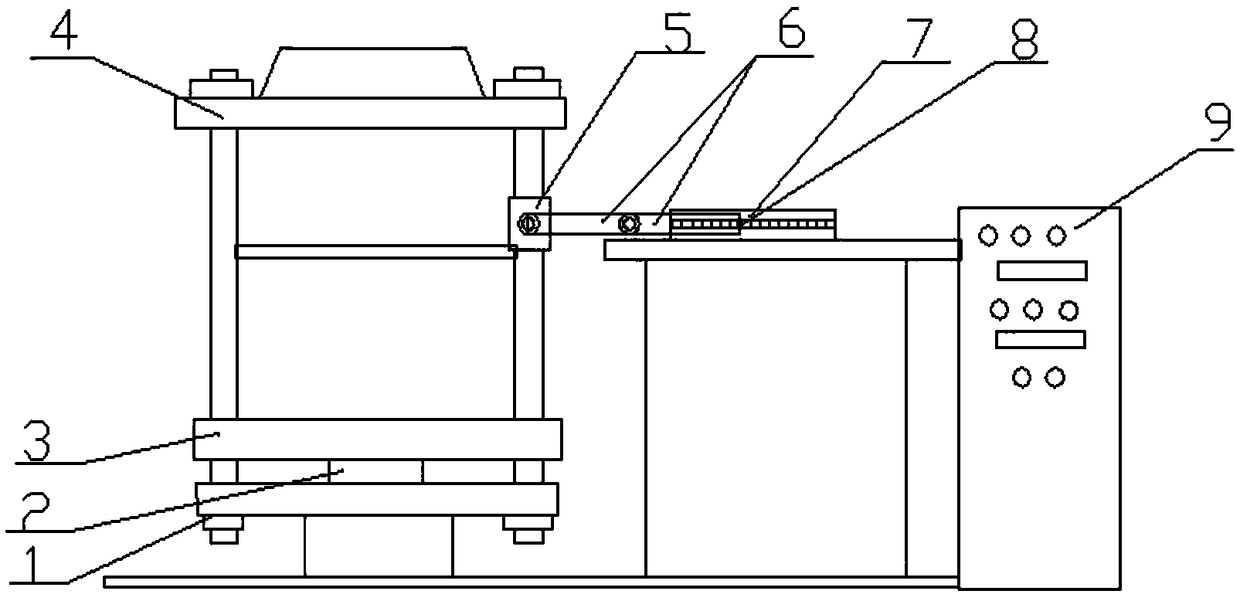

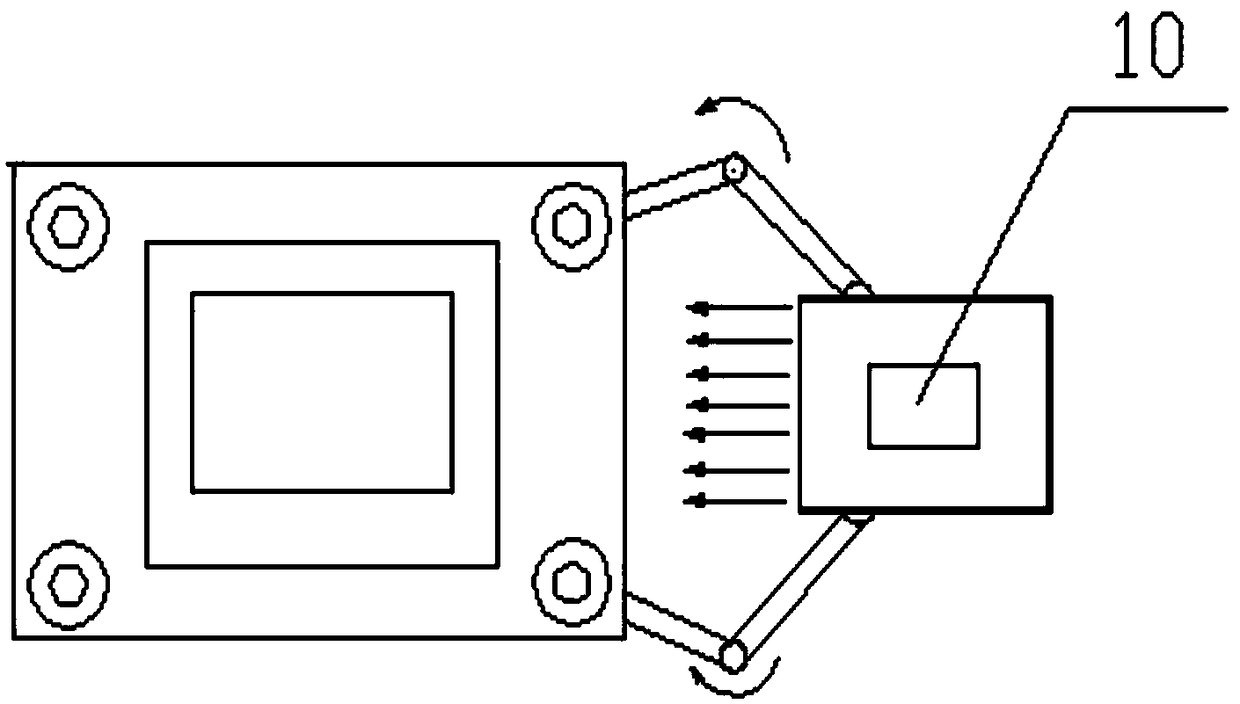

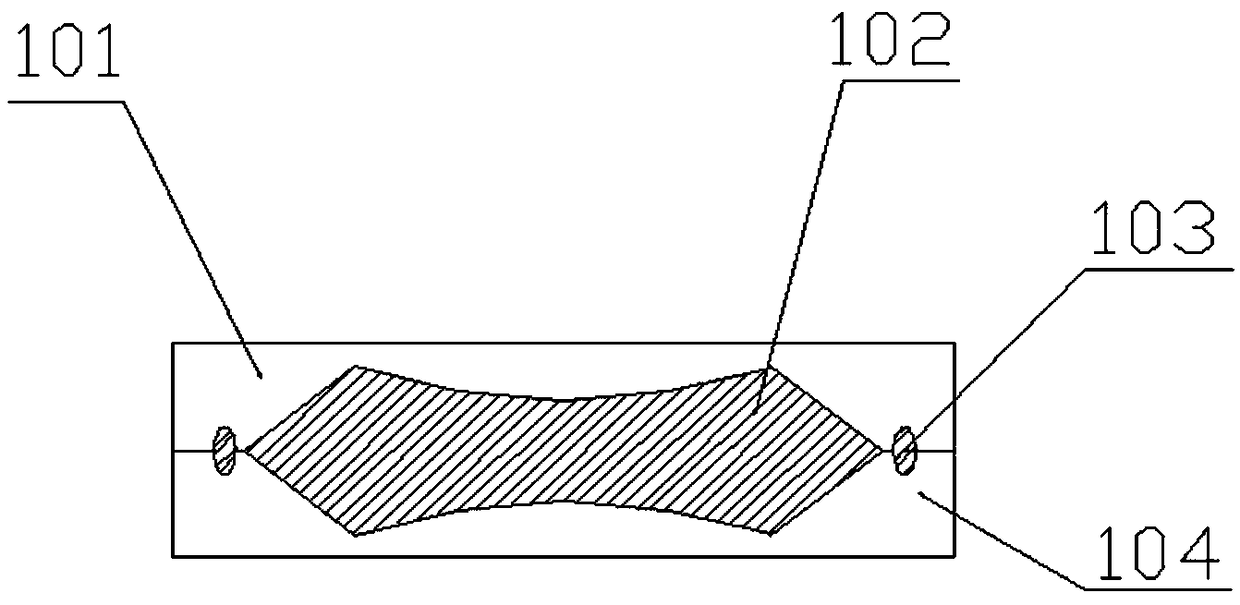

[0012] Such as figure 1 As shown, the column of the vulcanizer 1 is provided with 5 shaft sleeves, 6 connecting rods are connected to the 5 support columns, 7 formworks, and 8 sliders are installed on the 7 formworks.

[0013] In this example, in order to ensure the stability of No. 7 formwork during its movement, No. 7 formwork and No. 8 slider adopt hydraulic control.

[0014] In this example, the 5 rotating shaft sleeves are connected with 6 connecting rods, and the 6 connecting rods are connected with the 8 slide blocks through rotating pairs, and the movement of the 6 connecting rods is controlled by a hydraulic system.

[0015] In this example, the starting switch of the template heating wire in the 7th is connected with the 9th controller through a wire.

[0016] In this example, when the product is processed, the 8-slider is located at the limit position of the left end of the template in 7, and the 9-control box is controlled by the hydraulic system to control the 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com