Ultra-silence underwater propeller

A propeller, ultra-quiet technology, applied in the direction of underwater ships, underwater operation equipment, ships, etc., can solve the problems of difficult to overcome mechanical noise, unfavorable military underwater ships lurking, reconnaissance and attack, etc., to achieve the goal of overcoming mechanical noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

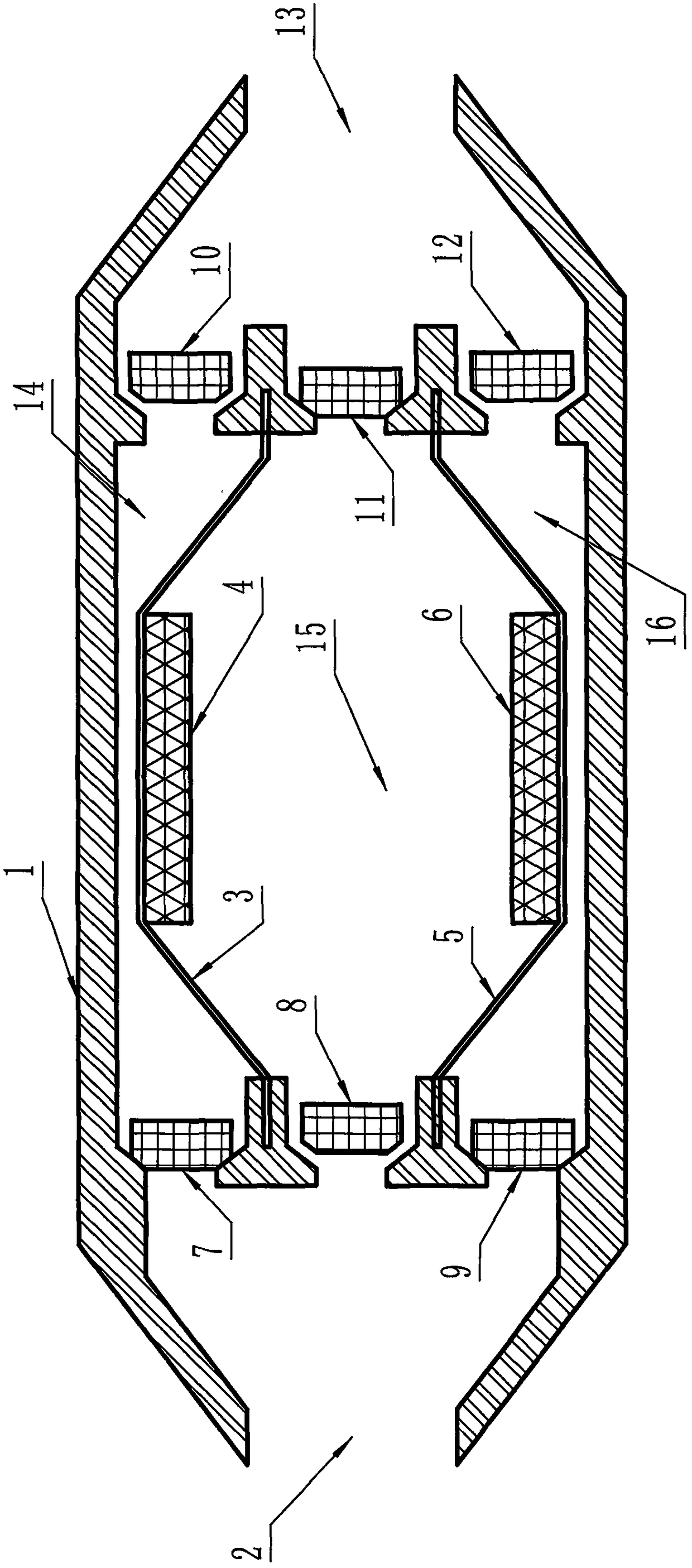

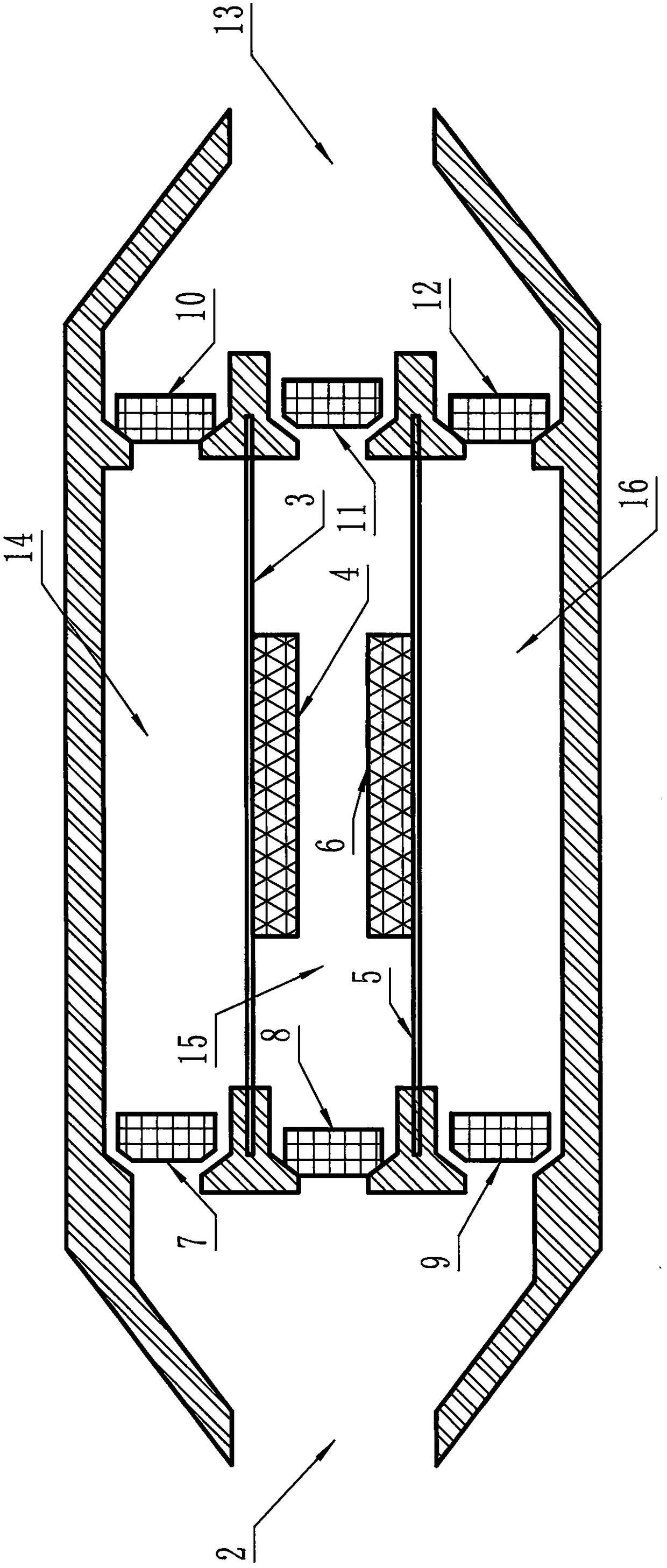

[0009] Such as figure 1 , figure 2 As shown, the present invention has a three-cavity structure and a one-way valve system that automatically controls the water flow in and out according to the movement of the cavities. There is a closed cavity between the water inlet 2 and the water outlet 13 of the shuttle-shaped housing 1, which is installed in the shuttle-shaped The rubber plate I 3 and the rubber plate II 5 on the shell 1 divide the cavity into three cavities: cavity I 14, cavity II 15 and cavity III 16, and a water inlet valve is installed at 2 water inlets of cavity I14 I 7, water outlet valve I 10 is installed at water outlet 13; water inlet valve II 8 is installed at the water inlet of cavity II 15, and water outlet valve II 11 is installed at the water outlet; water inlet valve III9 is installed at the water inlet of cavity 1II16, and water outlet Install the water outlet valve III12. Electromagnet I 4 is installed on the rubber plate I 3, and electromagnet II 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com