Synchronizing device, synchronizing device speed control system and vehicle

A technology of a synchronizing device and a vehicle, applied in the field of vehicles, can solve the problems that the synchronizing device does not have an energy recovery function, has a mechanical impact sound, and the speed regulation process is complicated, so as to improve the synchronization performance, reduce the secondary impact, and achieve good synchronization performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

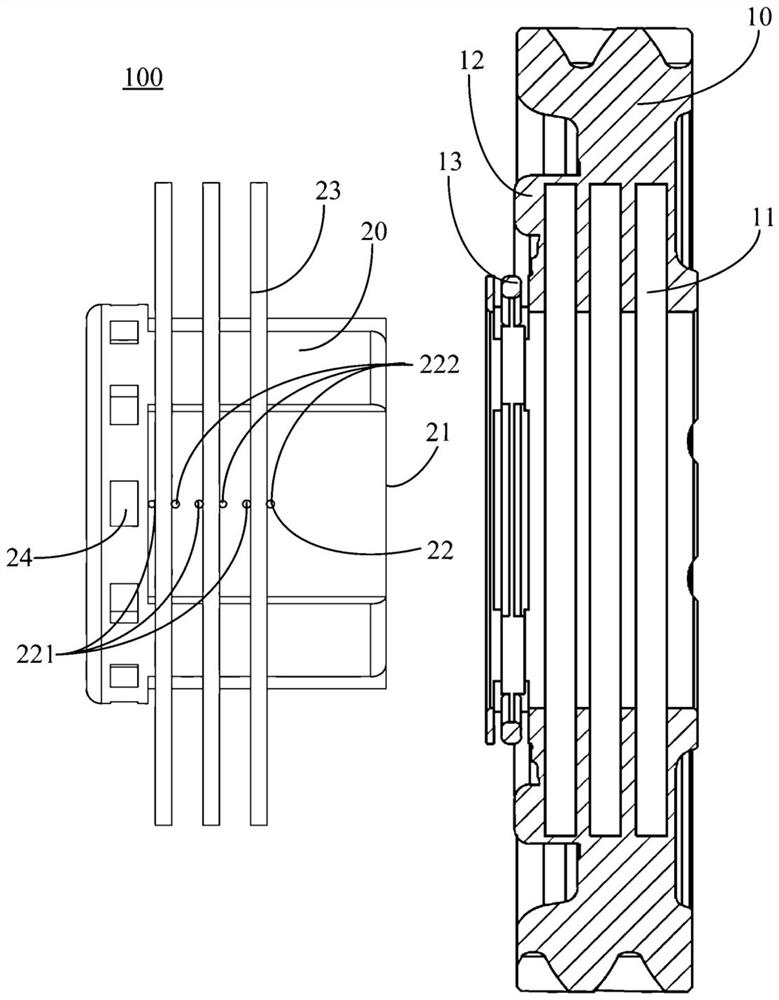

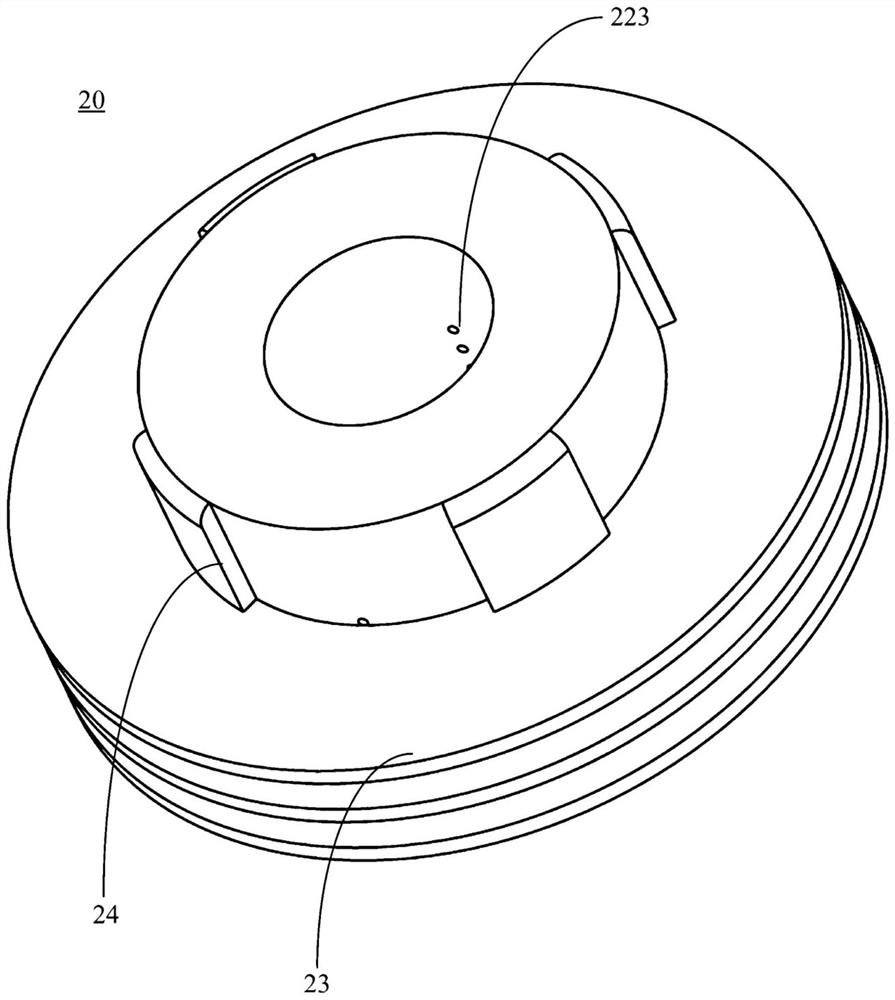

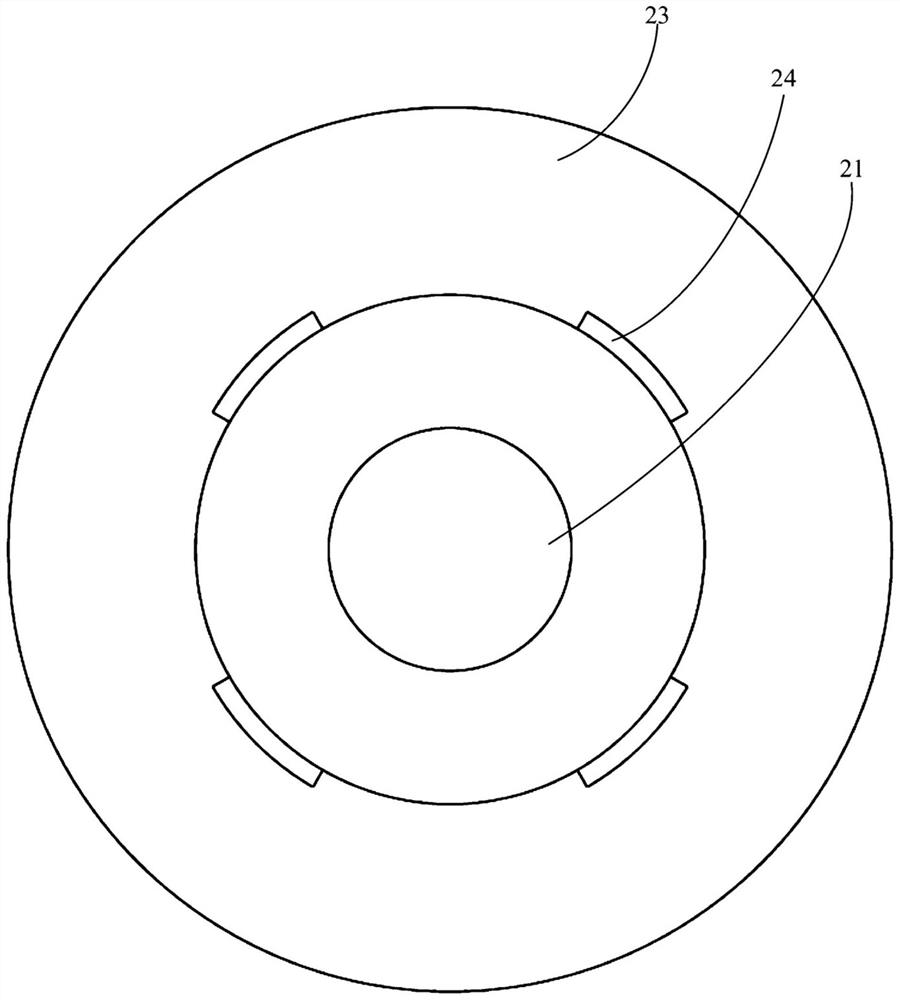

[0039] figure 1 It is a schematic structural diagram of the output shaft and the gear section of the synchronization device 100 according to an embodiment of the present invention. Specifically, the synchronization device 100 of this embodiment may include a gear 10 and an output shaft 20 . Wherein, the inner ring of the gear 10 is provided with a friction plate groove 11 . The output shaft 20 is provided with an oil inlet hole 21 with one end closed, and an oil outlet hole 22 communicating with the oil inlet hole 21 . A friction plate 23 is connected to the outer side of the output shaft 20 , and the oil outlet hole 22 can guide the hydraulic oil at the oil inlet hole 21 to the friction plate 23 . Wherein, the output shaft 20 is arranged on the inner ring of the gear 10, and the friction plate 23 is clamped at the groove 11 of the friction plate, and the hydraulic oil entering the output shaft 20 from the oil inlet hole 21 enters the groove of the friction plate from the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com