Device and method for reducing noise of microwave oven

A microwave oven, noise technology, applied in the field of microwave ovens, reducing noise during operation, can solve the problem of low heat dissipation efficiency, achieve the effect of improving heat dissipation efficiency, reducing noise, and solving mechanical noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

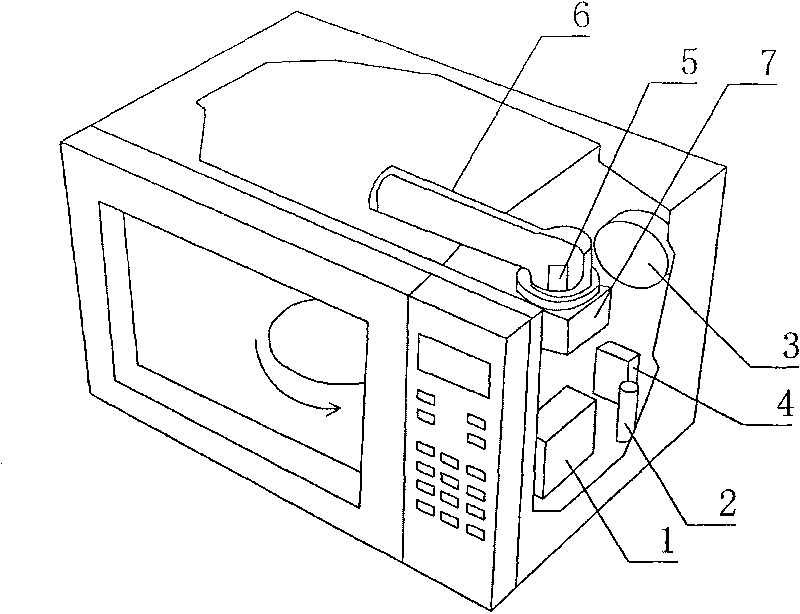

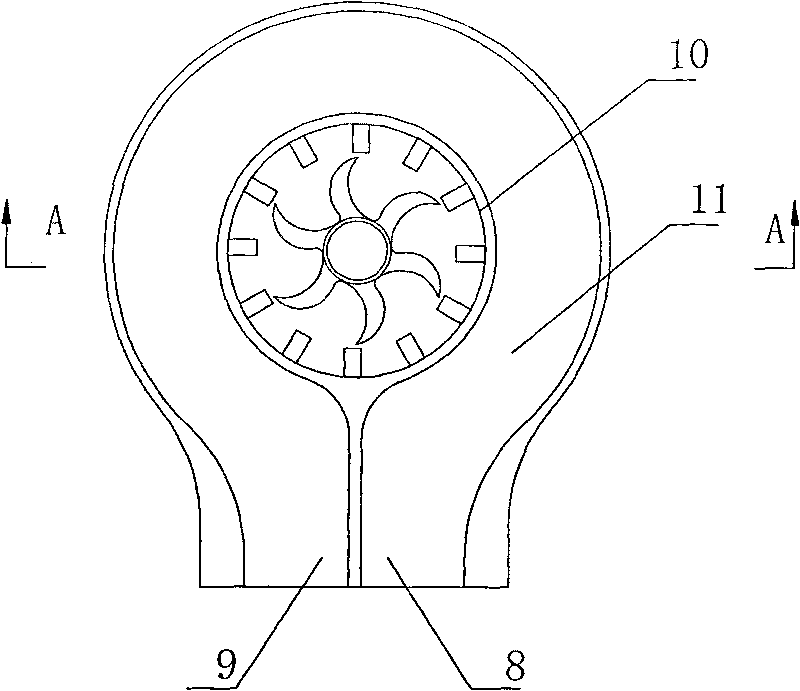

[0012] see Figure 1 to Figure 3 As shown, the cooling fan in the microwave oven is mainly designed for cooling the magnetron. When the microwave oven is working, the high-voltage electricity generated by the transformer is transmitted to the cathode filament of the magnetron. As the filament heats up, it emits electrons, which are attracted to the positively charged anode plate of the outer magnetron. A magnetic field exerted by some large magnet blocks spins the outwardly flowing electron cloud. As it spins, electron clouds form spokes that pass through each cavity between the anode plates. The moving electron cloud "spokes" transfer negative charges to the cavity, which then flows out of the cavity before the next "spoke" arrives. The repeated increase and decrease of negative charge creates an oscillating electromagnetic field at 2.45 gigahertz in the cavity. The antenna on the magnetron resonates at this frequency, emitting microwaves from its top tip. In this proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com