Composite multifunctional box bottom structure

A multi-functional and composite technology, applied in the direction of containers, packaging items, special packaging items, etc., can solve the problems of secondary damage to the items in the box, waste of resources, damaged items in the box, etc., to avoid excessive local temperature difference, The effect of preventing items from rotting and solving drainage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with specific embodiments.

[0038] The structural form of a kind of composite multifunctional box bottom structure in the present embodiment is:

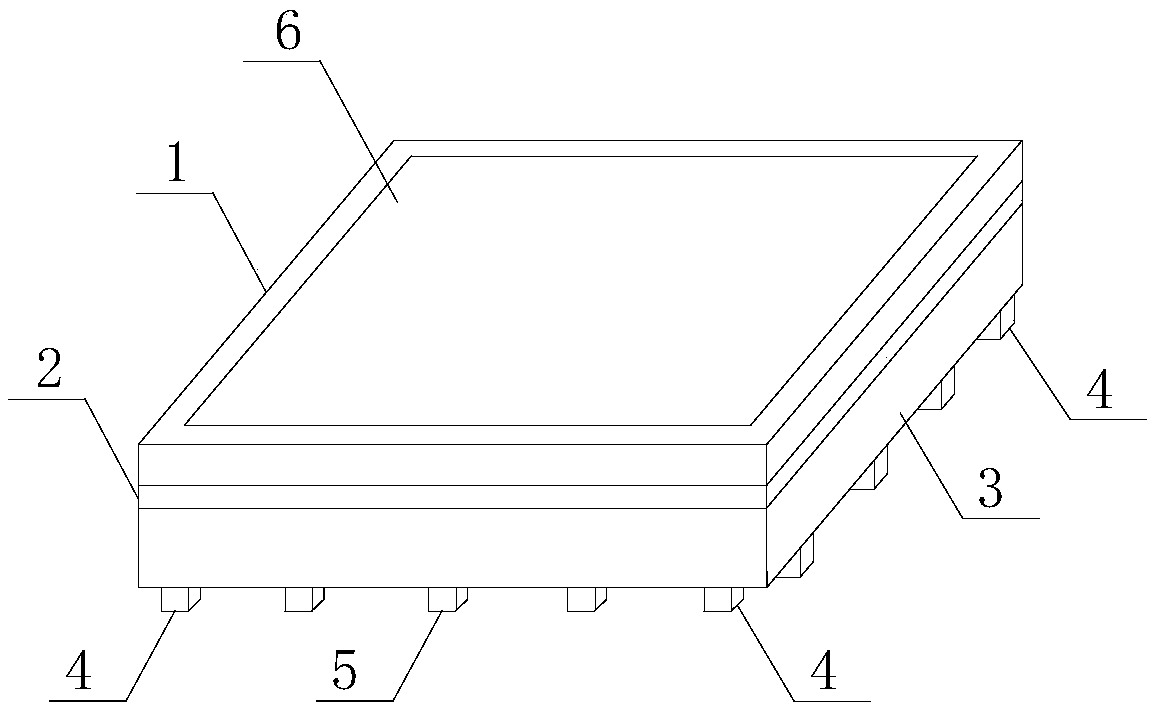

[0039] see figure 1 In this embodiment, the box bottom includes a functional layer 1 , a transition layer 2 , a buffer composite layer 3 , a corner connecting column 4 , a lattice pressure-bearing layer 5 and a grid leveling layer 6 .

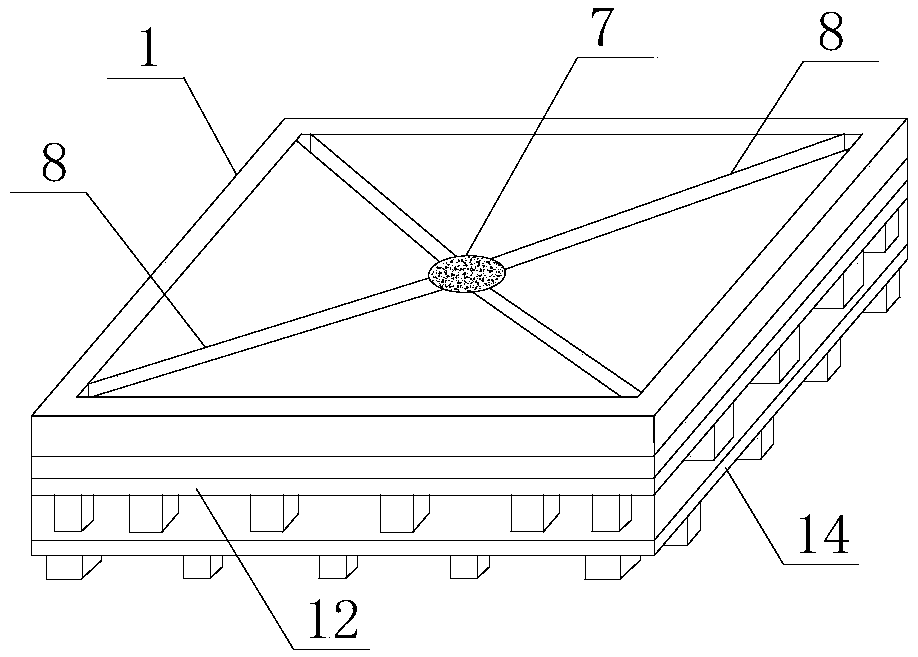

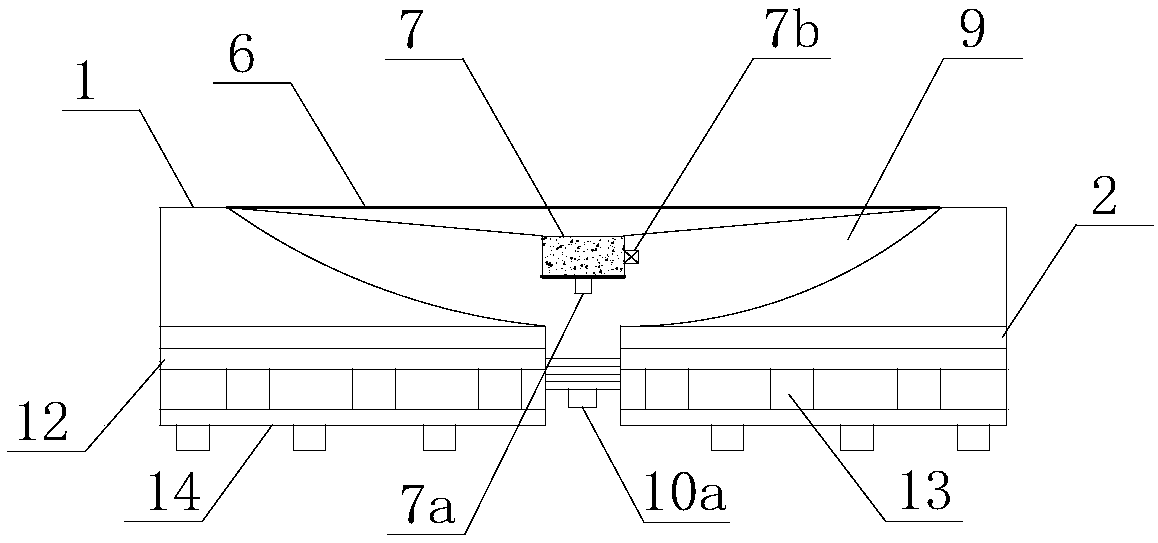

[0040] see Figure 2 to Figure 4 In this embodiment, a water collection filter hole 7 is provided in the center of the functional layer 1, and a diversion ditch 8 connected to the water collection filter hole 7 is provided on the functional layer 1. A functional chamber 9 connected to the water collection filter hole 7 is provided inside, a drip nozzle 7a is provided at the bottom of the water collection filter hole 7, and a water level monitoring device 7b is provided on one side of the water collection filter hole 7. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com