A method for preparing an electronic-grade hydrogen fluoride oxidation reaction device

An oxidation reaction, hydrogen fluoride technology, applied in hydrogen fluoride, fluorine/hydrogen fluoride, chemical/physical/physical-chemical stationary reactors, etc., can solve problems such as increasing the difficulty of treatment, cost, impact, non-compliance with technical specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

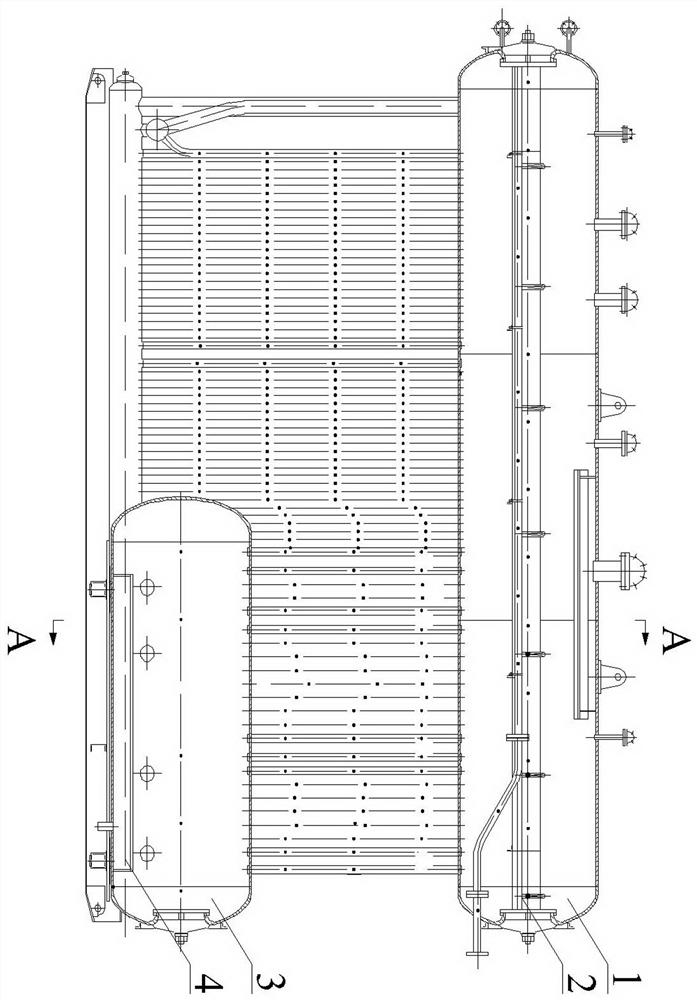

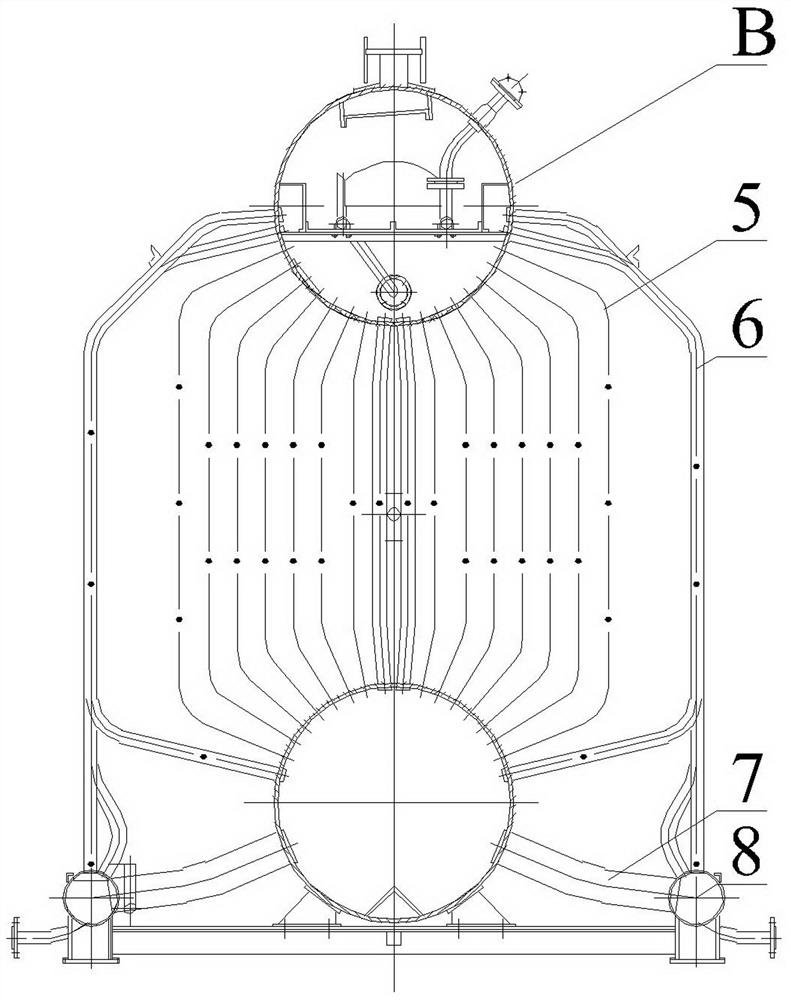

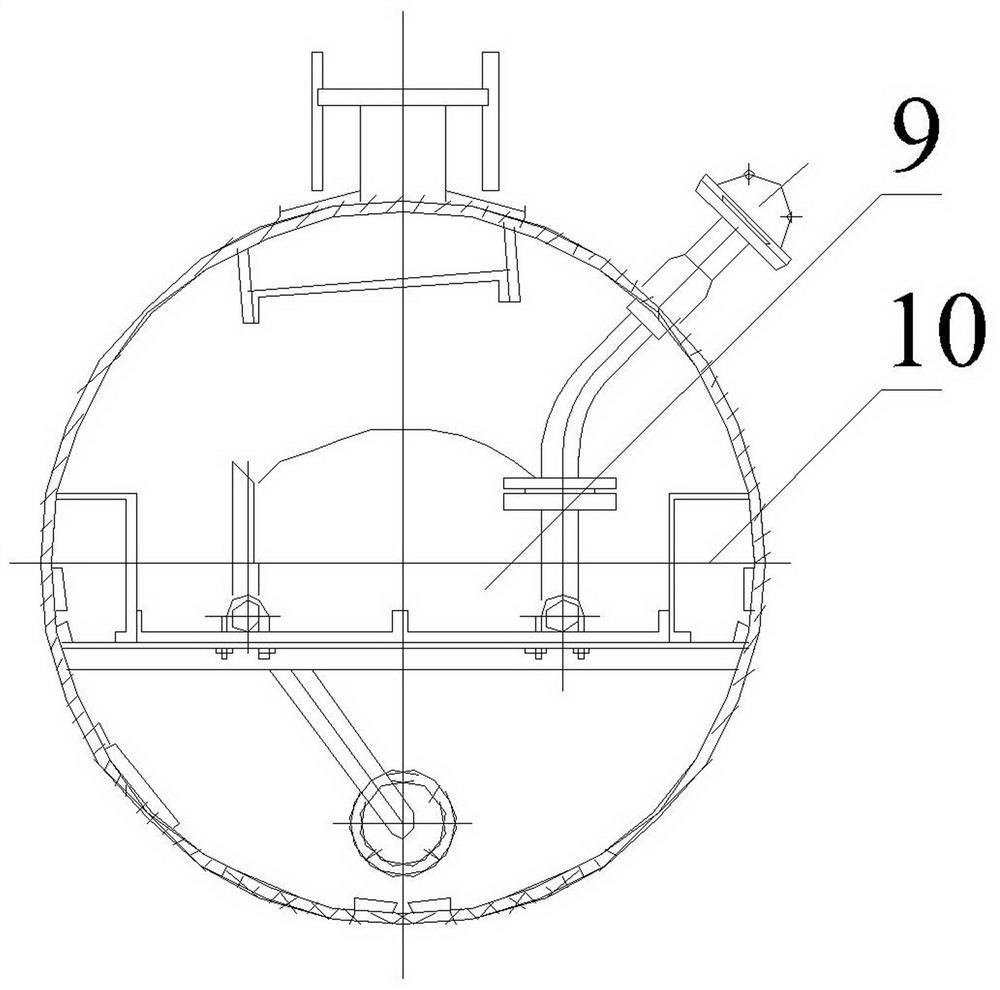

[0016] Such as figure 1 , figure 2 , image 3 As shown, a method for preparing an electronic-grade hydrogen fluoride oxidation reaction device is characterized in that:

[0017] Step 1: Inject anhydrous hydrogen fluoride into the circulation storage tank 3, observe through the sight glass, ensure that its liquid level is lower than the level of the gas-liquid separator 2 in the oxidation reaction kettle 1 by 3-5 cm, and feed fluorine gas into the oxidation reaction kettle 1, Keep the air pressure in the oxidation reactor 1 in balance with the ambient air pressure.

[0018]Step 2, the anhydrous hydrogen fluoride stored in the liquid collection tank 8 is heated and vaporized by the boiling exhaust pipe 6 and then sent to the oxidation reaction kettle 1, the heating temperature is 30-31°C, and the hydrogen fluoride in the boiling exhaust pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com