Low-temperature baking highlight high-performance coating and preparation method thereof

A low-temperature baking, high-performance technology, used in epoxy resin coatings, coatings, etc., can solve the problems of insufficient fullness of acrylic topcoats, inability to meet appearance requirements, slow drying speed of alkyd topcoats, etc., to improve the appearance , The paint film resistance is improved, and the paint liquid is in good condition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

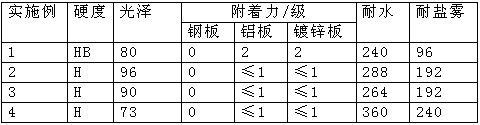

Examples

Embodiment 1

[0043] Water-based acrylic resin 50,

[0044] Waterborne epoxy resin 20,

[0045] Defoamer (Teco) 0.3,

[0046] Wetting agent (Teco) 0.3,

[0047] Dispersant (Teco) 1,

[0048] Leveling agent (Digo) 0.3,

[0049] Coalescing agent (alcohol ester twelve) 4,

[0050] Color paste (30% black paste) 8,

[0051] Functional filler water slurry (70% barium sulfate slurry) 10,

[0052] Deionized water 5.5,

[0053] Anti-flash rust agent (179) 0.5,

[0054] Thickener (299) 0.1,

[0055] In the dispersion equipment, ensure that the dispersion speed is maintained at 1000r / min, and then add water-based acrylic resin, water-based epoxy resin, conventional additives, film-forming additives, functional filler water slurry, anti-flash rust agent, and thickener in sequence , color paste, etc., disperse at high speed for 20-30 minutes, and disperse evenly. Then take the material and spray it on the board, level it for about 10 minutes, then transfer it to a 100°C oven, and keep it warm ...

Embodiment 2

[0057] Water-based acrylic resin 20,

[0058] Waterborne epoxy resin 50,

[0059] Defoamer (Teco) 0.3,

[0060] Wetting agent (Teco) 0.3,

[0061] Dispersant (Teco) 1,

[0062] Leveling agent (Digo) 0.3,

[0063] Coalescing agent (alcohol ester twelve) 4,

[0064] Color paste (30% black paste) 8,

[0065] Functional filler water slurry (70% barium sulfate slurry) 10,

[0066] Deionized water 5.2,

[0067] Anti-flash rust agent (179) 0.5,

[0068] Thickener (299) 0.4.

[0069] In the dispersion equipment, ensure that the dispersion speed is maintained at 1000r / min, and then add water-based acrylic resin, water-based epoxy resin, conventional additives, film-forming additives, functional filler water slurry, anti-flash rust agent, and thickener in sequence , color paste, etc., disperse at high speed for 20-30 minutes, and disperse evenly. Then take the material and spray it on the board, level it for about 10 minutes, then transfer it to a 100°C oven, and keep it warm ...

Embodiment 3

[0071] Water-based acrylic resin 35,

[0072] Waterborne epoxy resin 35,

[0073] Defoamer (Teco) 0.3,

[0074] Wetting agent (Teco) 0.3,

[0075] Dispersant (Teco) 1,

[0076] Leveling agent (Digo) 0.3,

[0077] Coalescing agent (alcohol ester twelve) 4,

[0078] Color paste (30% black paste) 8,

[0079] Functional filler water slurry (70% barium sulfate slurry) 10,

[0080] Deionized water 5.3,

[0081] Anti-flash rust agent (179) 0.5,

[0082] Thickener (299) 0.3.

[0083] In the dispersion equipment, ensure that the dispersion speed is maintained at 1000r / min, and then add water-based acrylic resin, water-based epoxy resin, conventional additives, film-forming additives, functional filler water slurry, anti-flash rust agent, and thickener in sequence Wait, disperse at high speed for 20-30 minutes, and disperse evenly. Then take the material and spray it on the board, level it for about 10 minutes, then transfer it to a 100°C oven, and keep it warm for 30-40 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com