Slope greening structure and method combined with high-strength pre-compressed anchor rod and prefabricated reinforced concrete slab

A technology for reinforced concrete slabs and slopes, which is applied in basic structural engineering, botanical equipment and methods, and excavation to achieve the effects of reducing slope sliding, reducing the probability of anchor rods contacting water and air, and reducing manual input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

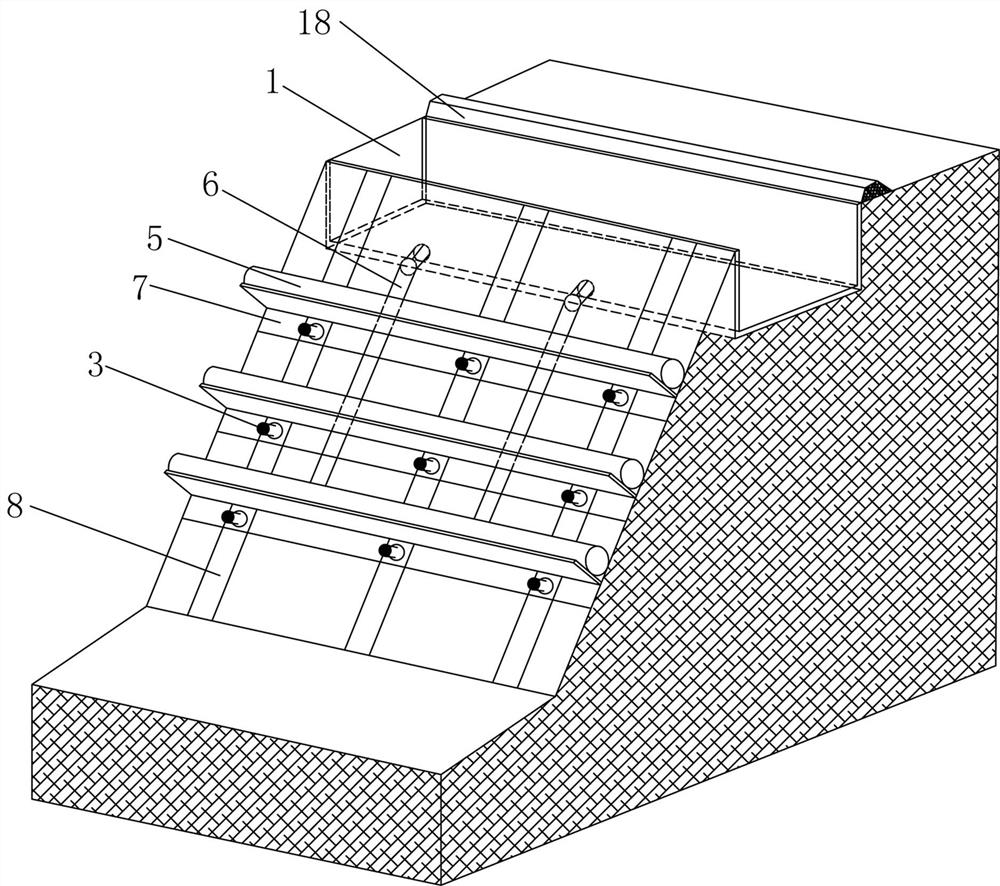

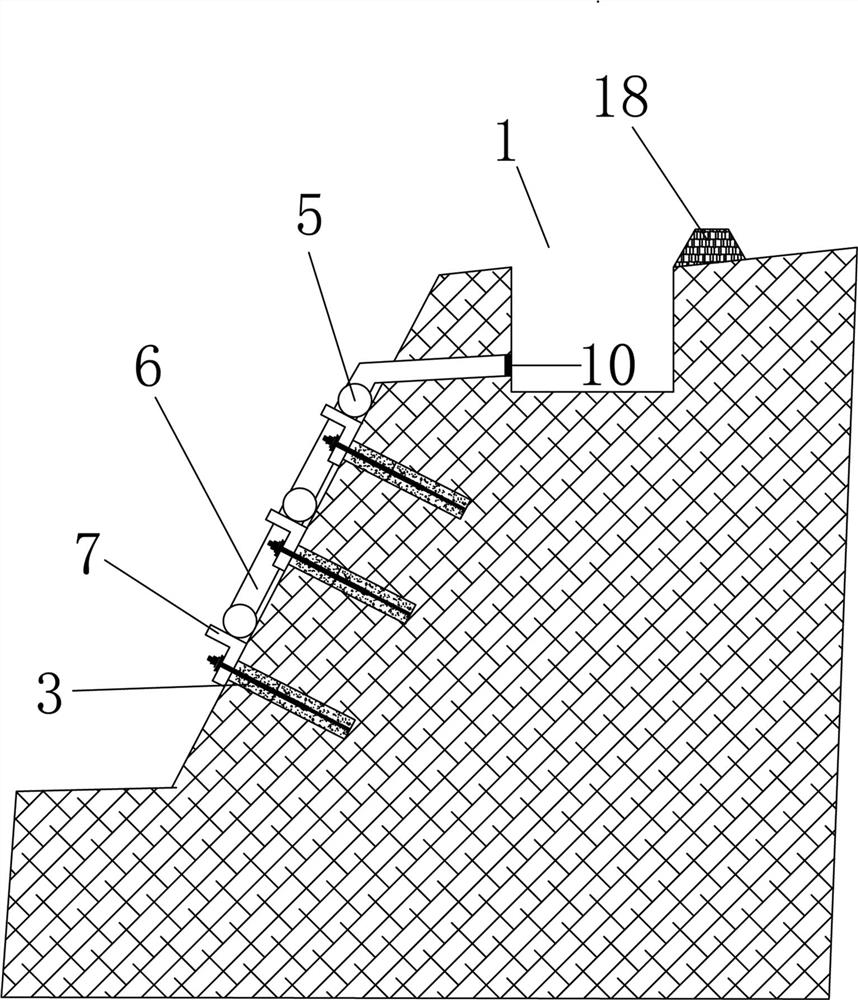

[0037] Such as Figure 1-Figure 5 As shown, a high-strength preloaded anchor rod and prefabricated reinforced concrete slab combined slope greening structure, including a water collection tank 1 set on the top of the slope, and a number of transverse prefabricated steel bars are evenly arranged on the slope surface from top to bottom The concrete slab 7 and the horizontal prefabricated reinforced concrete slab 7 are fixed and installed on the slope surface through a plurality of high-strength pre-stressed anchor rods 3, and each horizontal prefabricated reinforced concrete slab 7 is placed with a horizontal water supply pipe 5 with both ends closed, and the horizontal water supply pipe 5 is provided with a plurality of water outlet holes 9, and the outer surface of the horizontal water supply pipe 5 is wrapped with a dialysis membrane. Each horizontal water supply pipe 5 is connected with the water collection tank 1 through the vertical water supply pipe 6. concrete piles;

...

Embodiment 2

[0047] A method for slope greening using the above structure, the method includes the following steps:

[0048] Step 1: Clean up the side slope, using manual and simple machinery to remove gravel and sundries on the side slope, the order should be from top to bottom;

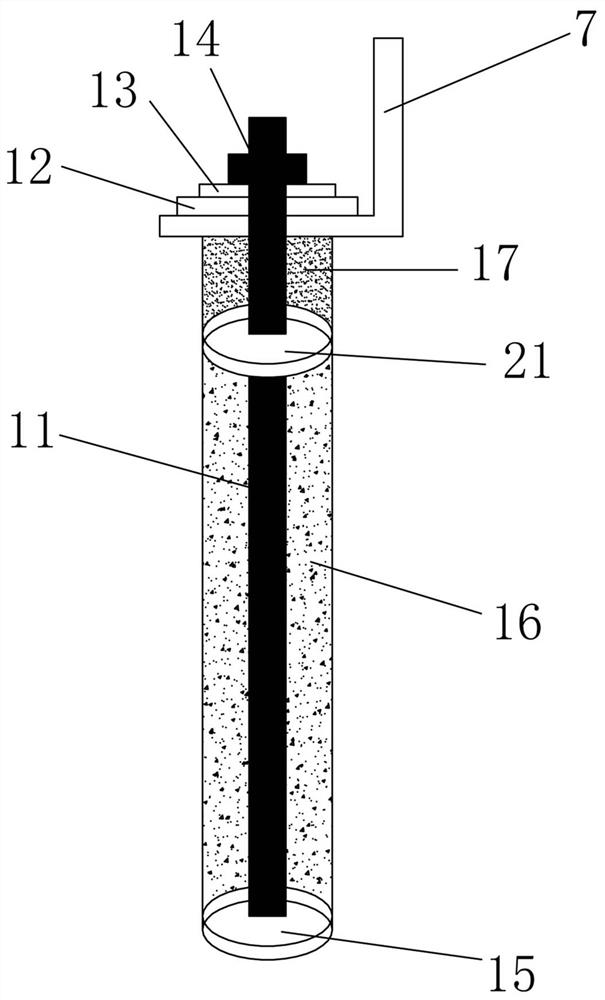

[0049]Step 2: Drill multiple anchor holes on the slope surface, insert the anchor rod 11 with the first rigid disc 15 into the anchor hole, add cement mortar with a mass content of 10-30% expansion agent into the anchor hole to solidify A high-strength preloaded anchor body 16 is prepared, and a second rigid disk 21 is arranged on the top of the high-strength preloaded anchor body 16, so that the axial pressure on the anchor rod 11 is converted into a lateral pressure, and the pullout resistance of the anchor rod is increased. Add cement mortar into the anchor hole and solidify to make ordinary mortar anchor body 17;

[0050] Step 3: Connect the horizontal prefabricated reinforced concrete slab 7 and the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com